10

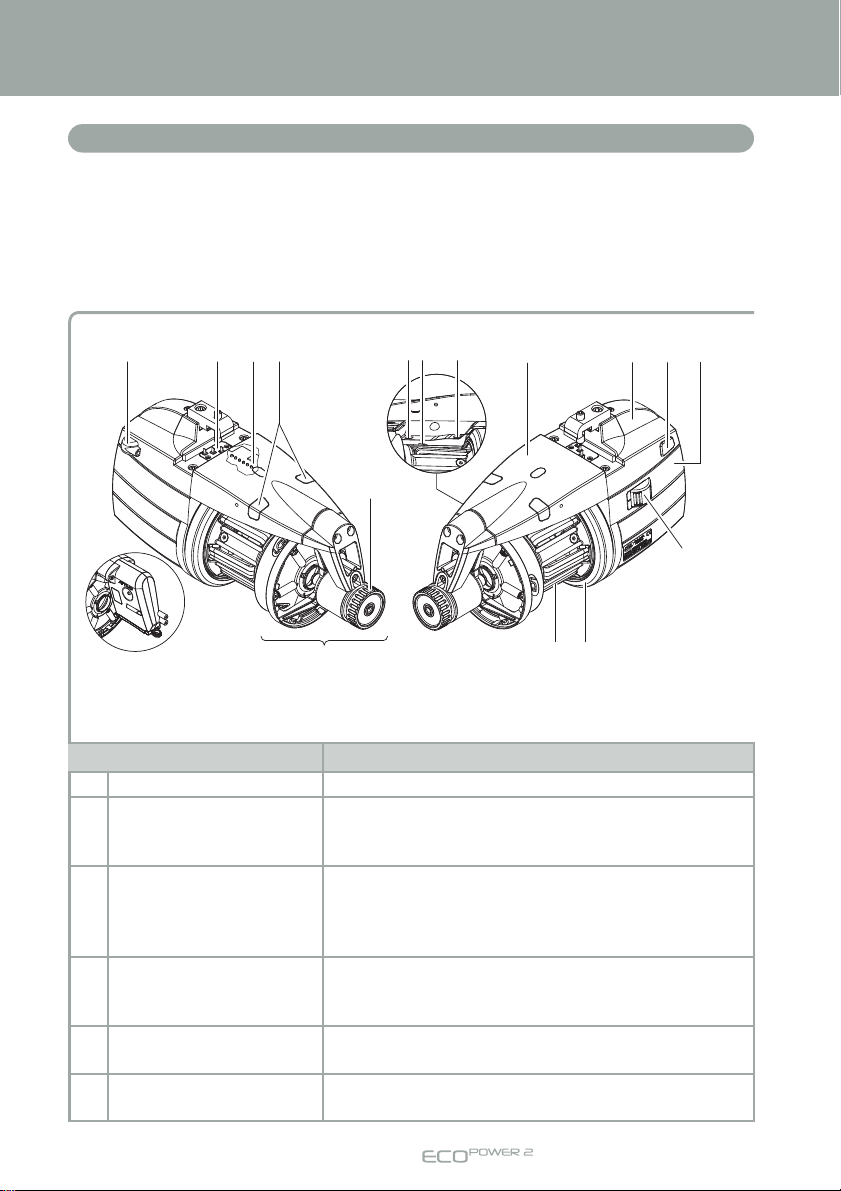

1 GENERAL FEATURES

Intended Use:

The ECOPOWER2 is a yarn feeder featuring separate coils, suitable for all types of

knitting machines or for textile machines requiring yarn feed-in with constant tension.

Optimised operation is provided with yarn counts ranging from 800 den (the thicker yarn

counts) down to 5 den (fine yarn counts).

IMPROPER uses

Improper uses are all those uses which are not expressly indicated among the design uses, namely:

- Working of yarns other than those specified

- Power supply of the machine not matching the specified value

- Use of the machine in an explosive atmosphere.

Operational features:

•Automatic speed adjustment designed to cover the machine’s yarn quantity requirements.

•Spool body winding reserve control by means of a magnetic feeler system.

•Yarn feeder and machine stop function if no yarn is detected at the feeder’s yarn input

(broken yarn or empty yarn bobbin).

•Kit KLS:

Feeder and machine stop function when no yarn is found on feeder outlet without using

mechanical sensors (yarn broken or out of the needles).

•The option of being able to fit on various tensioning devices based on the type of yarn

actually being used, at both the feeder’s inlet and outlet.

•Either vertical set-up or horizontal set-up assembly option, selectable based on requirements.

•Real-time detection and display function of the yarn consumption related to each machine feed

•ATTIVO electronic tensioner (optional). The operator sets the desired output tension, and

the system will maintain it, to avoid all tension changes depending on the yarn, the bobbin

and the like issues.

Technical specifications:

•Power supply by means of a direct connection with the machine, or through a power

supply box that is supplied separately by L.G.L. Electronics.

Power supply voltage data: V = 42-48 VAC three-phase Hz = 50/60 (AC version)

V = 57 VDC (DC version)

•Automatic yarn input speed control provided up to a maximum of 1000 m/min.

•Coil separation feature fixed at 1 mm (STD); 2 mm (Z1).

•Permanent magnet synchronous motor.

•Motor data:

Maximum power: 35 W

•Equivalent continuous A-weighted sound pressure level at maximum speed: <70 dB (A)

•Operation and storage conditions:

- Room temperature: from +10 to +40 °C

- Maximum humidity: 80%

1.3 INTENDED USE TECHNICAL AND OPERATIONAL FEATURES

1 GENERAL FEATURES