Lifetime 65027 User manual

Other Lifetime Outdoor Cart manuals

Lifetime

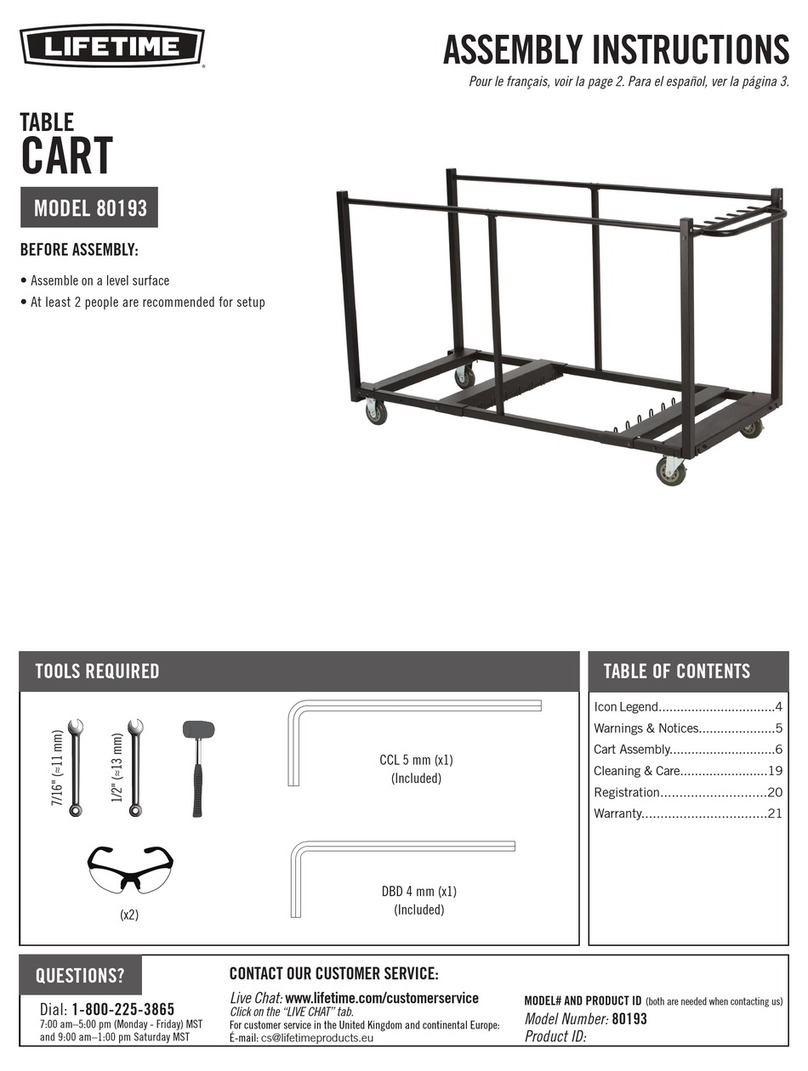

Lifetime 80193 User manual

Lifetime

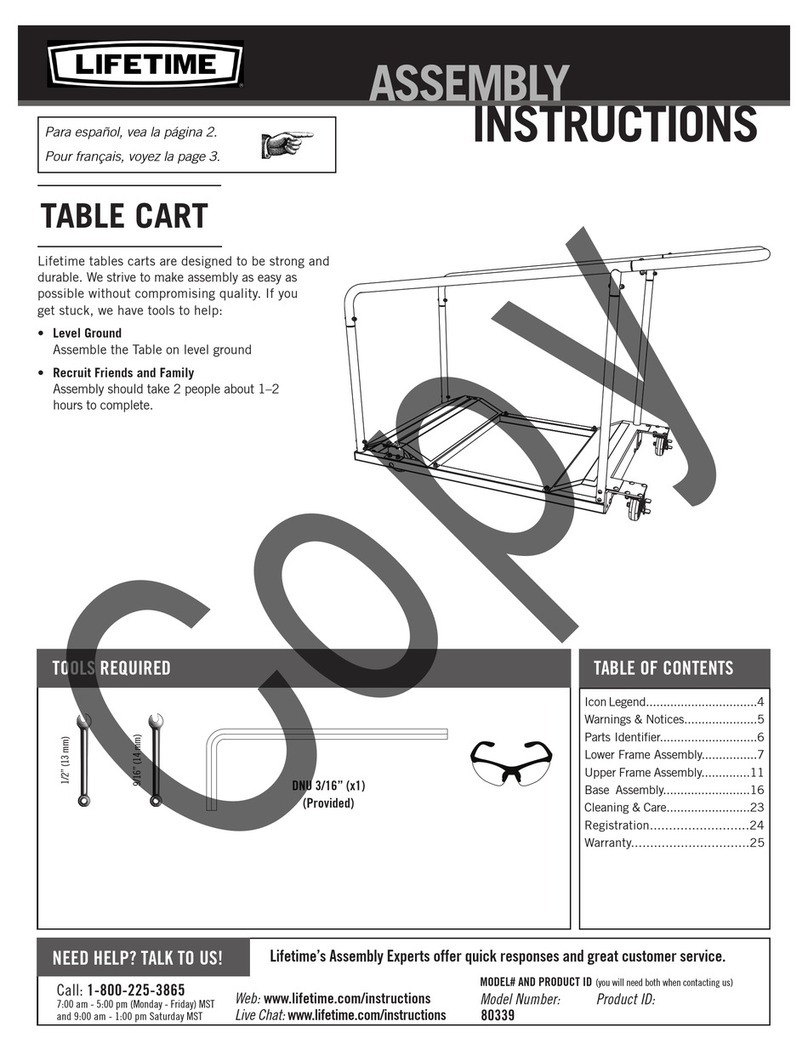

Lifetime 80339 User manual

Lifetime

Lifetime 6520 Quick start guide

Lifetime

Lifetime 90790 User manual

Lifetime

Lifetime 80669 User manual

Lifetime

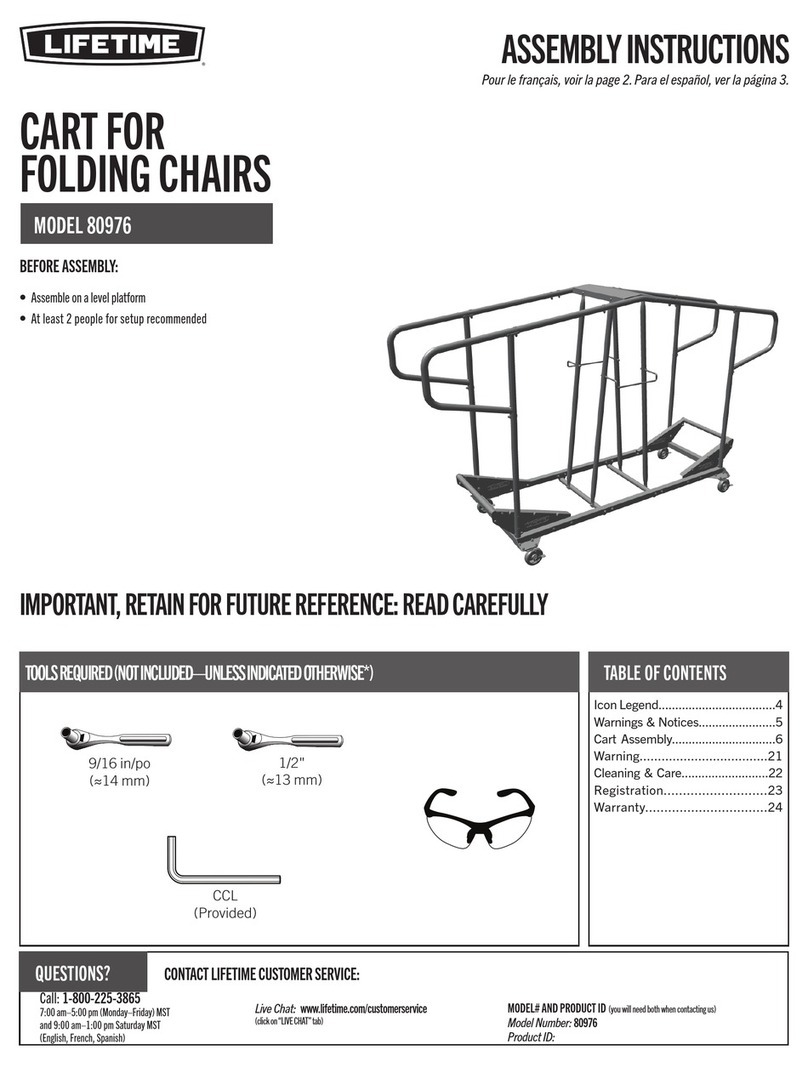

Lifetime 80976 User manual

Lifetime

Lifetime 80193 User manual

Lifetime

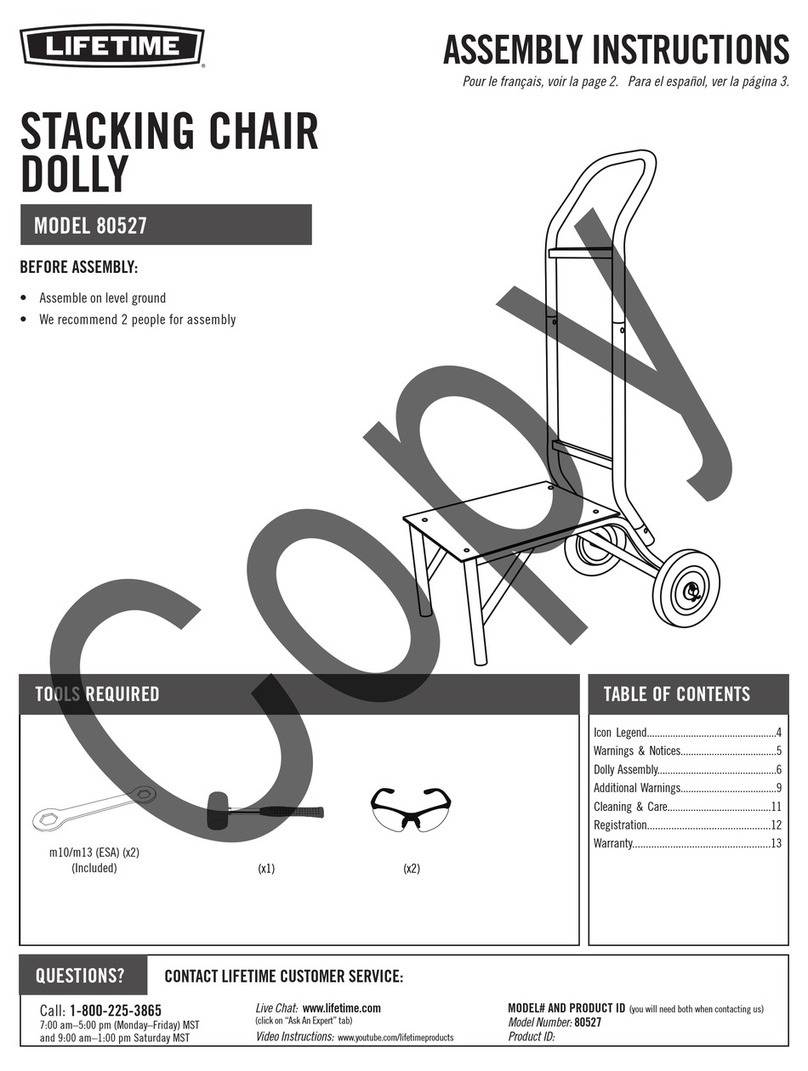

Lifetime 80527 User manual

Lifetime

Lifetime 80279 User manual

Lifetime

Lifetime 90367 User manual