DEVICE DESCRIPTION

The UV-FLOW .... C-NX is a controlled unidirectional flow device, with a powerful UV lamp inside and a narrow emission

peak at wavelength of 235.7 nm. (nanometers), which has a strong germicidal effect against all micro-organisms (molds,

bacteria and viruses).

There is also a parabolic, mirror bright aluminum surface, which generates UV ray parallel beams by reflection. These

beams pass through a black honeycomb laminated grid that directs UV rays to form a unidirectional flow ("blade UV").

When installed according to the instructions, this device can be used in the presence of people for intensive and

continuous air disinfection.

OPERATION

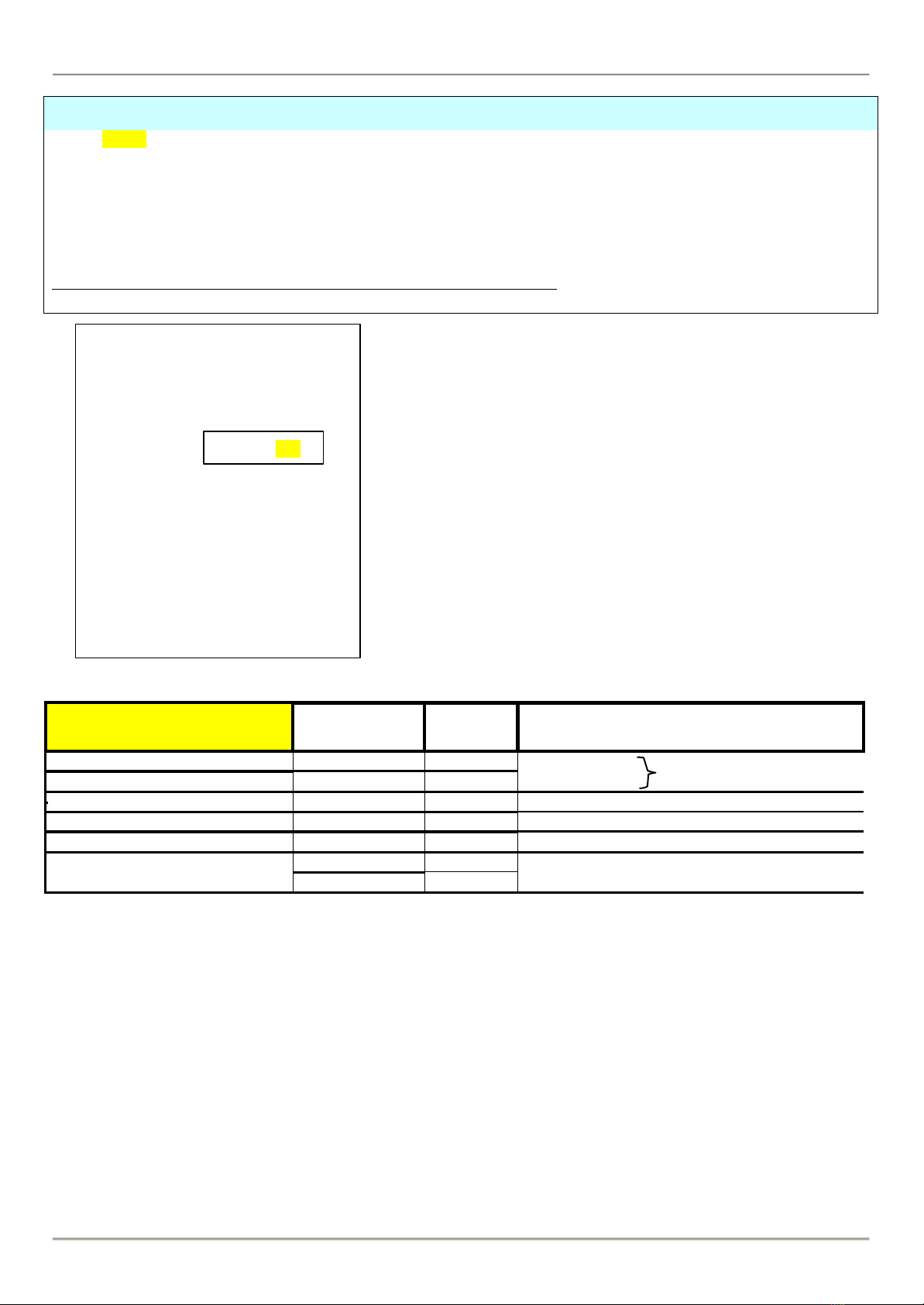

The UV-FLOW .... C-NX must be anchored at the wall and can be oriented so to generate a horizontal flow or a vertical

downward flow.

HORIZONTAL FLOW:

This arrangement will create a "zone of intense radiation" below the ceiling, which destroys all airborne microorganisms,

due to natural convection of air (see pic. 1)

The air, rich in microbes, is continuously treated and disinfected by the ultraviolet rays; a progressive decontamination

of bacteria, viruses and molds is made, decreasing the possibility of bacterial, viral transmissions and contaminations

in general.

Continuous operation ensures a permanent progressive healthy environment, especially in hospitals, schools,

restaurants, indoor workplaces such as offices, laboratories, etc. An extremely important disinfection activity can be done

in hospital intensive cares units, to prevent the spread of diseases such as TB and other transmissible pathologies through

air.

VERTICAL FLOW:

This arrangement is positioned above the doors of controlled contamination rooms (clean rooms), with air flow directed

downwards. This arrangement generates a vertical air flow which produces a barrier against germs (pic. 2).

For proper use you should create a decontamination area between two adjoining rooms, to be kept under microbiological

and hygienic control. This zone can be made simply by a double opening, door and Avant-door, just over the front door

wide and about 1.5 to 2 meters deep.

The use of the UV-C-FLOW .... NX allows intense disinfection of that contaminated air entering microbiologically con-

trolled rooms when doors are opened. It is necessary in healthcare where transmission of bacteria, viruses, and airborne

spores is highly probable.

The application is also needed for food production areas, where it is necessary to work in very good microbiological

conditions.

BENEFITS AND ADVANTAGES

BLOCK OF GERMS

Blocking the spread of germs from one place to another (in case of using VERTICAL flow). Then you can keep at

consistently low levels the entry of germs into "controlled contamination" rooms.

PHYSICAL ACTION AND ENVIRONMENTAL PROTECTION.

Treatment by UV-C rays is purely physical, and always achieves the same effect; Also, there are no problems of over-

dose and rooms are safe and practicable (when devices are off). Rather, many methods of chemical treatment involve

the use of dangerous products for the environment, and difficult to biodegrade, as well as the risk of contamination of

foodstuffs. Whereas, the use of chemicals it is likely to develop resistant microbial forms with consequent danger to

human health.

DEEP AND ONGOING DISINFECTION

UV-FLOW can work 24 hours over 24 in the presence of people, thus allowing to maintain a consistently low level of

microbial environment.

PRACTICABILITY AND SAVINGS.

The treatment is immediate and ready for use. The maintenance is minimal with low costs of both energy consumption

and repairs.