Multi-Wavelength Pattern Scanning System - LightLas 532 / 670 - Service Manual Page 6 Rev. No 01

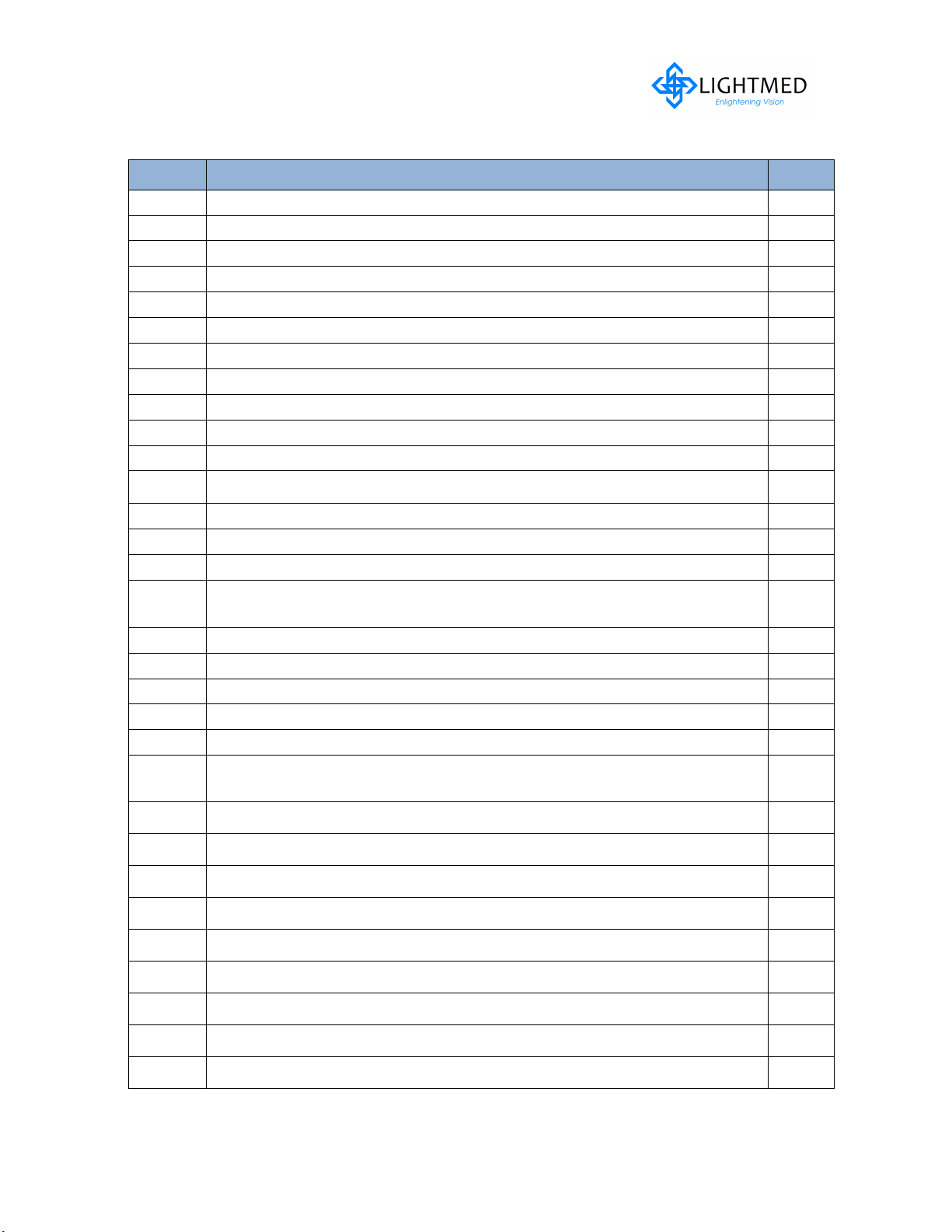

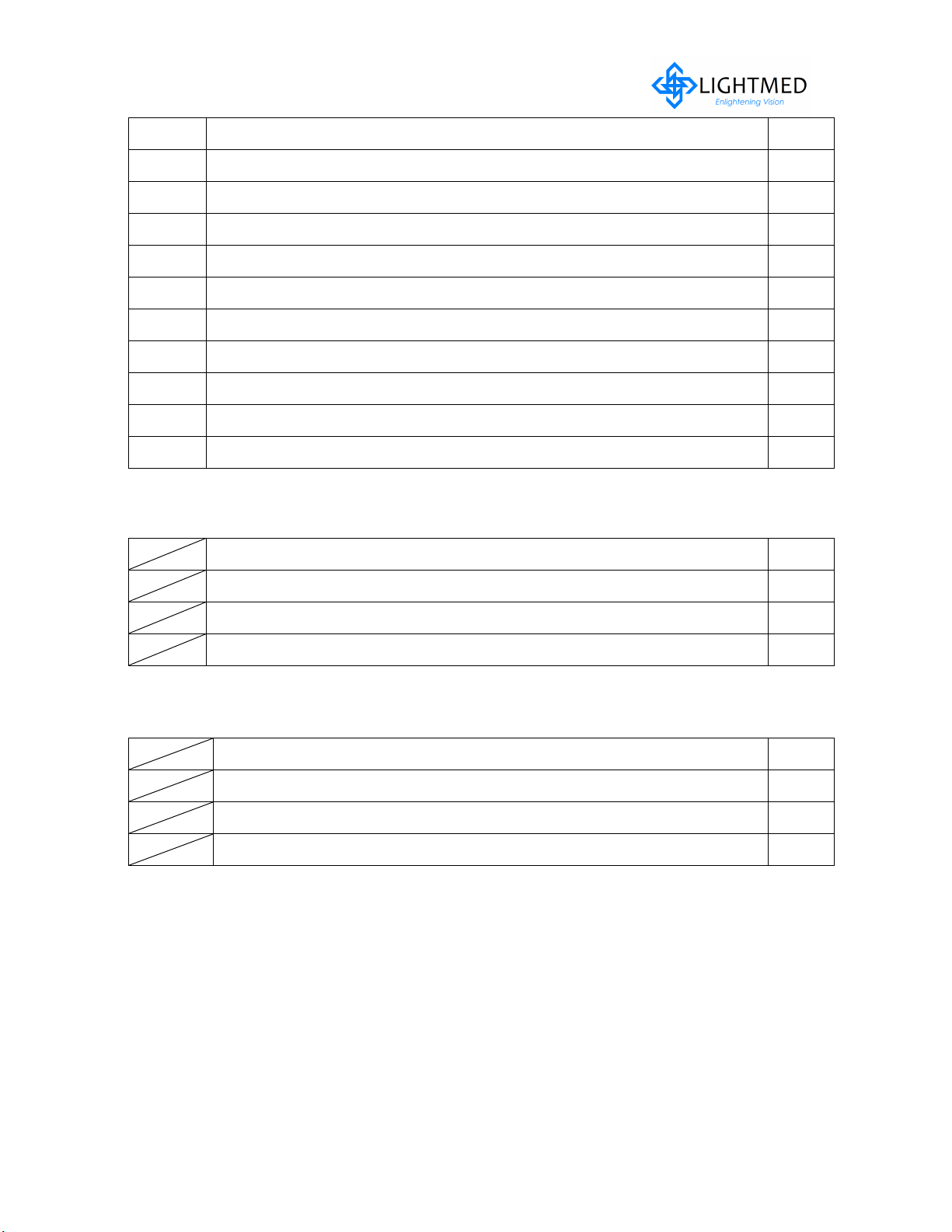

A. Microprocessor PCB Replacement .........................................................71

B. DC / DC Main PCB Replacement .............................................................72

C. DC Power Supply Module Replacement ...............................................73

Section 7 CALIBRATION / ALIGNMENT PROCEDURES ................................................74

7.1 Truscan Laser Power and Detector Calibration Procedures ........................74

A. 532nm Power Calibration Procedures (Port 1 / Port 2) .........................75

B. Software Calibration for All Different Power Range (100 - 2000mW) .78

C. 532nm Power Display Calibration Procedures (Port 1 / 2) ...................80

D. Software Calibration for All Different Power Range (50 - 2000mW) ...82

E. 670nm Power Calibration Procedures (Port 1) .....................................83

F. Software Calibration for All Different Power Range (100 - 700mW) ...86

G. 670nm Power Detector Procedures (Port 1) ........................................88

H. Software Calibration for All Different Power Range (50 - 700mW) for

Port 1 ...................................................................................................90

7.2 Aiming Spot Position Realignment Procedures ..........................................93

A. Fine Tuning ..............................................................................93

B. Coarse Tuning ......................................................................................95

C. Aiming Spot Stability Realignment Procedures (X / Y Axis) .................99

D. Spot Size Realignment Procedures (50 - 1000um) ..............................101

7.3 Slit Lamp Realignment Procedures ...........................................................102

7.4 Aiming Intensity Realignment Procedures .................................................103

A. Aiming VR Intensity Adjustment .........................................................103

B. Aiming Realignment Procedures .........................................................103

Section 8 MAINTENANCE ...........................................................................................106

8.1 Operator / User Maintenance …………………………………………….106

8.2 Laser Beam Alignment Check …………………………………………….107

8.3 System Output Power Checking Procedure ……………………………..108

8.4 Transmission Rechecking Process ..............................................................109

Section 9 TROUBLESHOOTING ...................................................................................109

9.1 Symptom …………………………………………………………………..111

9.2 Warning …………………………………………………………………...113

A. LCD Warning ..........................................................................................113

B. Remote Control Warning .....................................................................119

9.3 Error Codes ……………………………………………………………..120

Section 10 SOFTWAR UPGRADING PROCEDURES …………………………….124

10.1 Introduction ................................................................................................124

10.2 Preparation .................................................................................................124

10.3 Driver Software Downloading Procedures ................................................124

10.4 Software Installation Procedures ................................................................126

A. Window 7.0 or Above ..........................................................................126

B. Window XP ...........................................................................................131