2

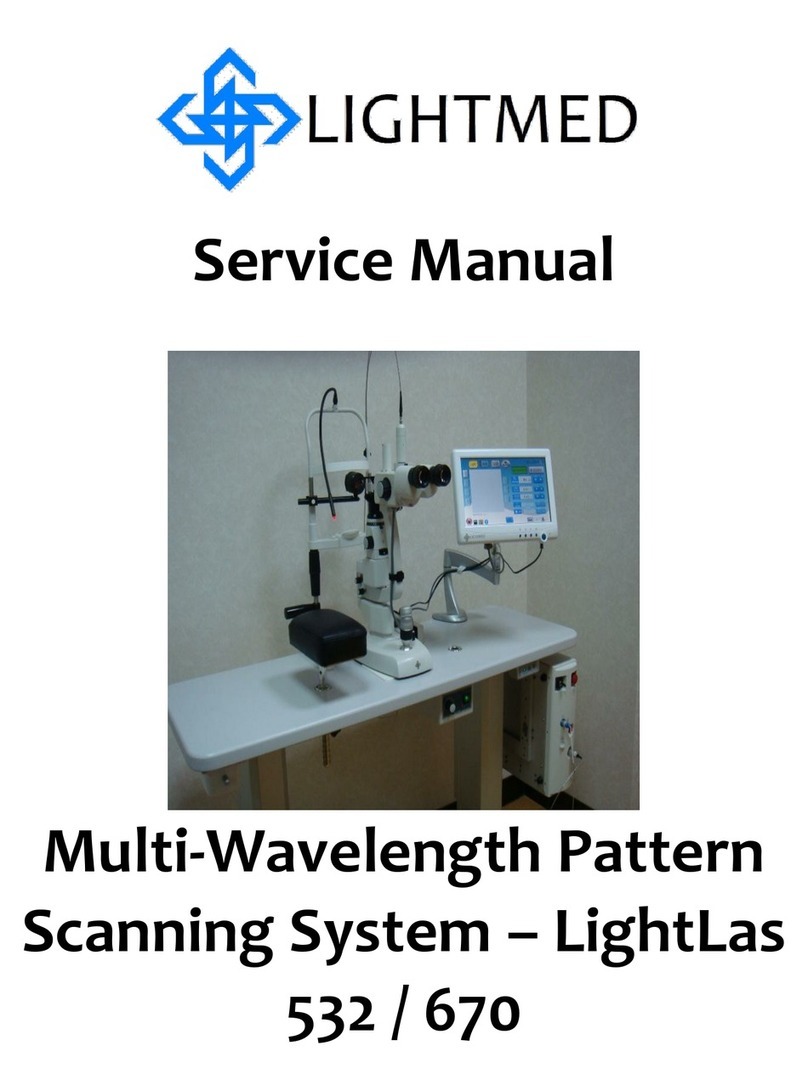

Service Manual for the LightLas 532 Medical Frequency

Doubled YAG Laser

Only authorized Service personnel should attempt to perform the procedures contained within

this Service Manual. The manufacturer can organise detailed Service Training for authorized

agents.

The manufacturer will under no account accept any responsibility for any conditions arising as

a result of unauthorized maintenance or adjustments to the LightLas 532 Medical Frequency

Doubled YAG Laser.

This Service Manual should be fully studied and understood before proceeding to operate or

service the equipment. For further details relating to the operation of the LightLas 532 Medical

Frequency Doubled YAG Laser the Service Manual should be referred to.

CAUTIONS - Use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

Any modification to the LightLas 532 Medical Laser will result in the necessity for it to be

reclassified.

CAUTIONS - US Law restricts this device to sale by or on the order of a physician.

This Service Manual contains confidential and proprietary information of the

manufacturer.

Manufactured by: LightMed Corporation, No.1-1, Ln. 1, Pao-An St.

Sec. 3,Shulin Dist., New Taipei City 23861, Taiwan

USA Address: 1030 Calle Cordillera, Suite 101, San Clemente, CA 92673

Tel No.: 949-218-9555 Fax No.: 949-218-9556

Copyright ©LightMed Corporation

EU Representative: Medical Device Safety Service GmbH

Schiffgraben 41, 30175 Hannover, Germany

Document Title: Service Manual for the LightLas 532 Medical Frequency Doubled YAG

Laser.

Document Number: DC2000-532

Document Revision History:

October 2001 - Draft prepared

March 2002 - Second version updated information

May 2002 - Third version with new Installation section, new drawings,

CE Mark information, Change to Revision 01

March 2003 - Rev.02 Modify drawings

February 2004 - Rev. 03 Safety Glasses description change; Delete Warranty

Statement

January 2005 - Rev. 04 Change EU Representative to ALF in ITALY