IS585 ECN 3858 Page 8 of 20

SITING

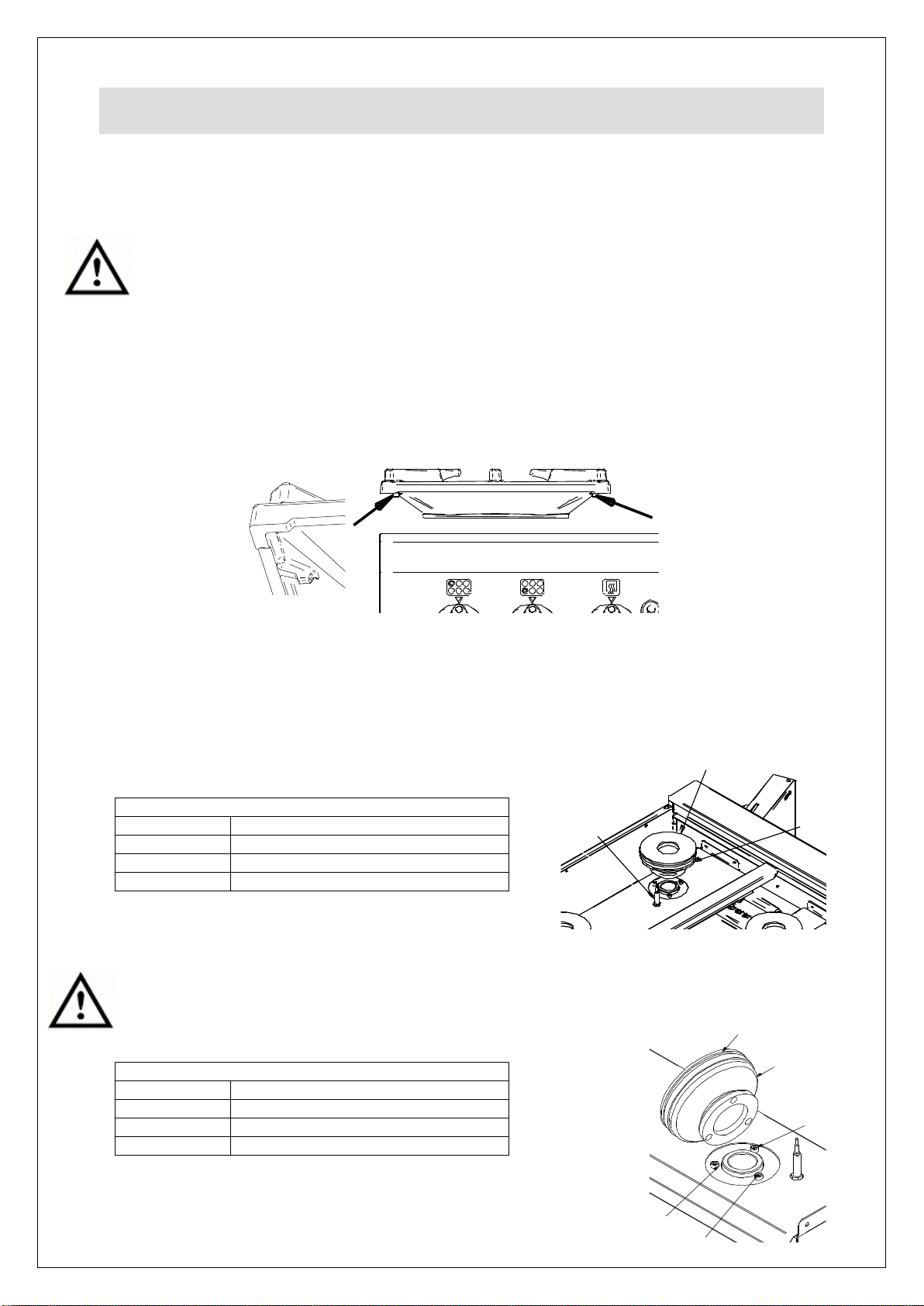

The installer must ensure that all regulations are met and that there is an unobstructed

minimum distance of 1000mm from the top of the flue to the ceiling, which must be of

non-combustible material.

The appliance should be installed on a level surface ensuring the unit is stable and

firmly located.

Any partitions, walls or kitchen furniture in close proximity must be of non-combustible

materials and not be closer than 50mm from the sides and rear of the flue.

The Installer shall pay particular attention, in order not to disturb the air combustion

admission nor the combustion products evacuation of appliances fitted with open burners.

GAS SUPPLY AND CONNECTION

The gas inlet connection is at the rear of the appliance. The pipe work should be of

adequate size but not smaller than the gas inlet connection at the rear of the appliance,

i.e. Rp ½” BSP (OG8001) & Rp ¾” BSP (OG8002).

The gas supply tubing or hose shall comply with national requirements in force and shall

be periodically inspected and replaced as necessary.

All joints made must be leak free.

Final gas connection to the appliance and gas supply shall comply with local regulations.

When making the connection to the appliance an isolating cock should be fitted into the

supply line close to the unit, for emergency shutdown or servicing purposes.

SUPPLY PRESSURES

The appliance is connected directly to the gas supply where the gas supply pressure

is controlled at the source of inlet in the building or via the governor attached to the

bottle gases. See Technical Data for the supply pressures.

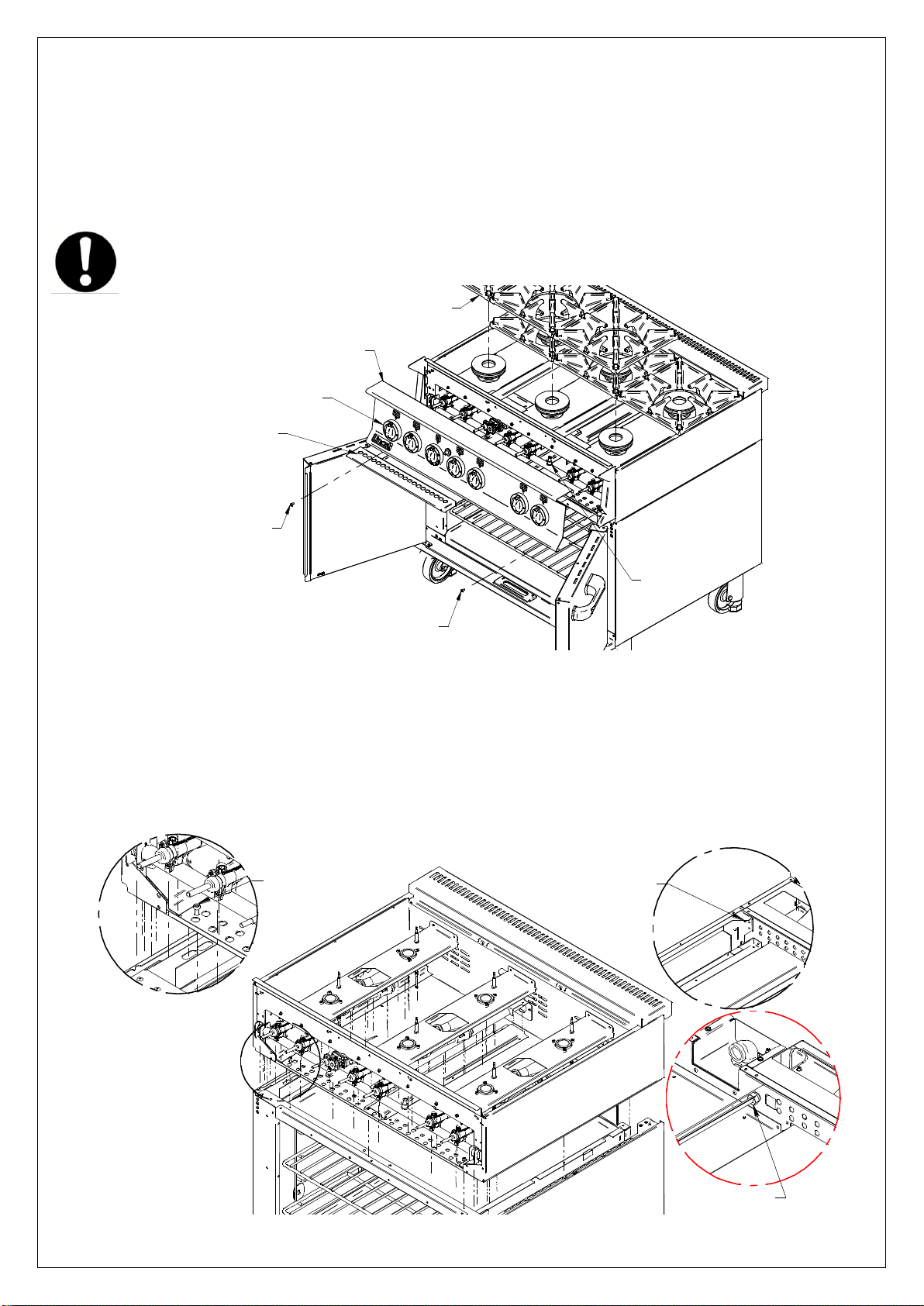

To gain access to the gas pressure test nipple the fascia panel requires removal.

The test nipple is situated in the centre of the manifold rail.

Remove the blanking screw and attach a pressure gauge to the boss of the test nipple.

Light the oven burner and set thermostat to the highest setting and check the pressure.

For Propane with a 50mbar supply pressure a govenor is required for

adjustment to 37mbar.

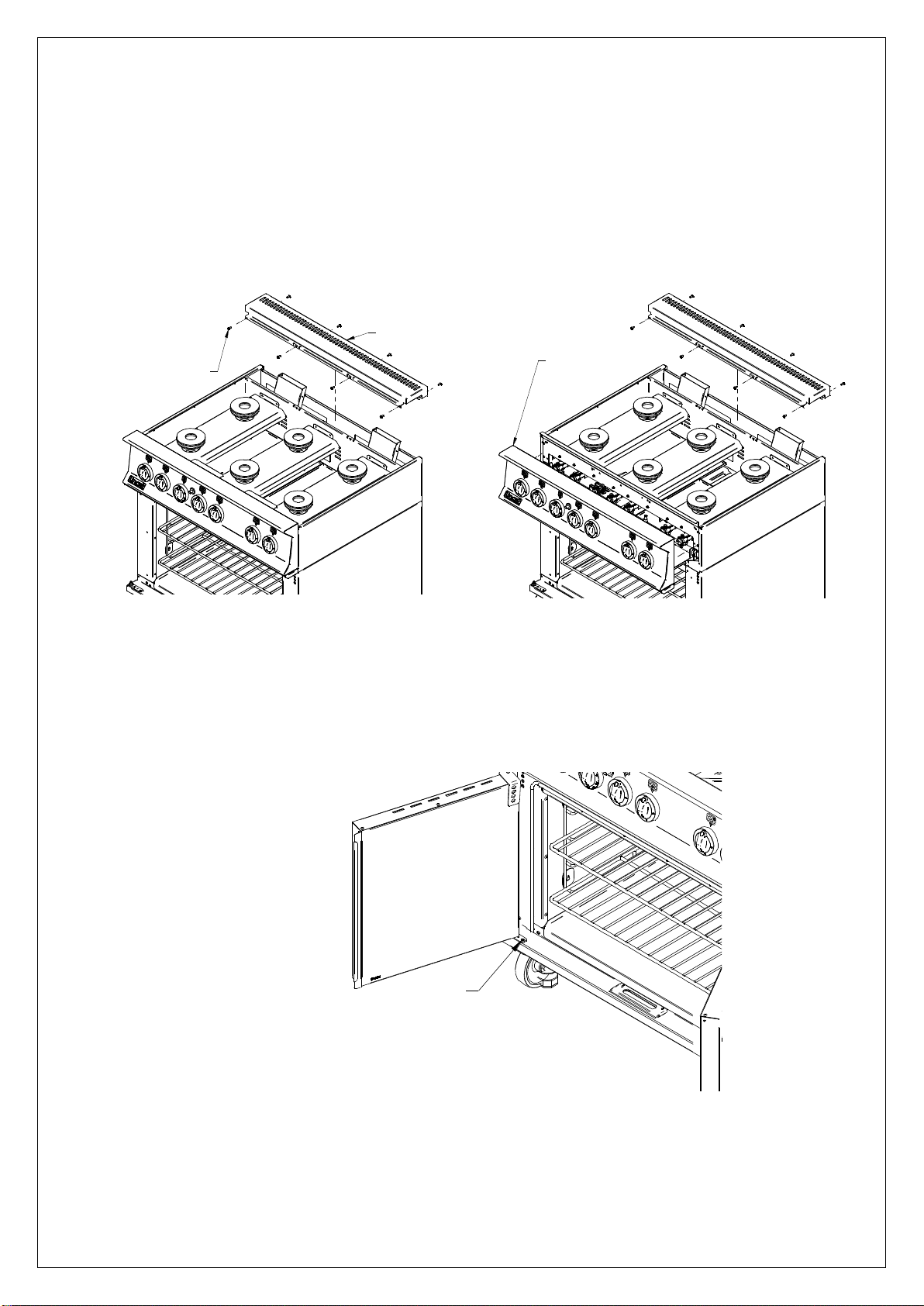

LOCKING OF WHEELS

When the appliance has been installed in its intended position the front casters should

be locked by depressing the locking tabs on the castors.

Locks should only be released for the intention of moving the appliance

for cleaning purposes and or routine servicing of the appliance.