8695 4788

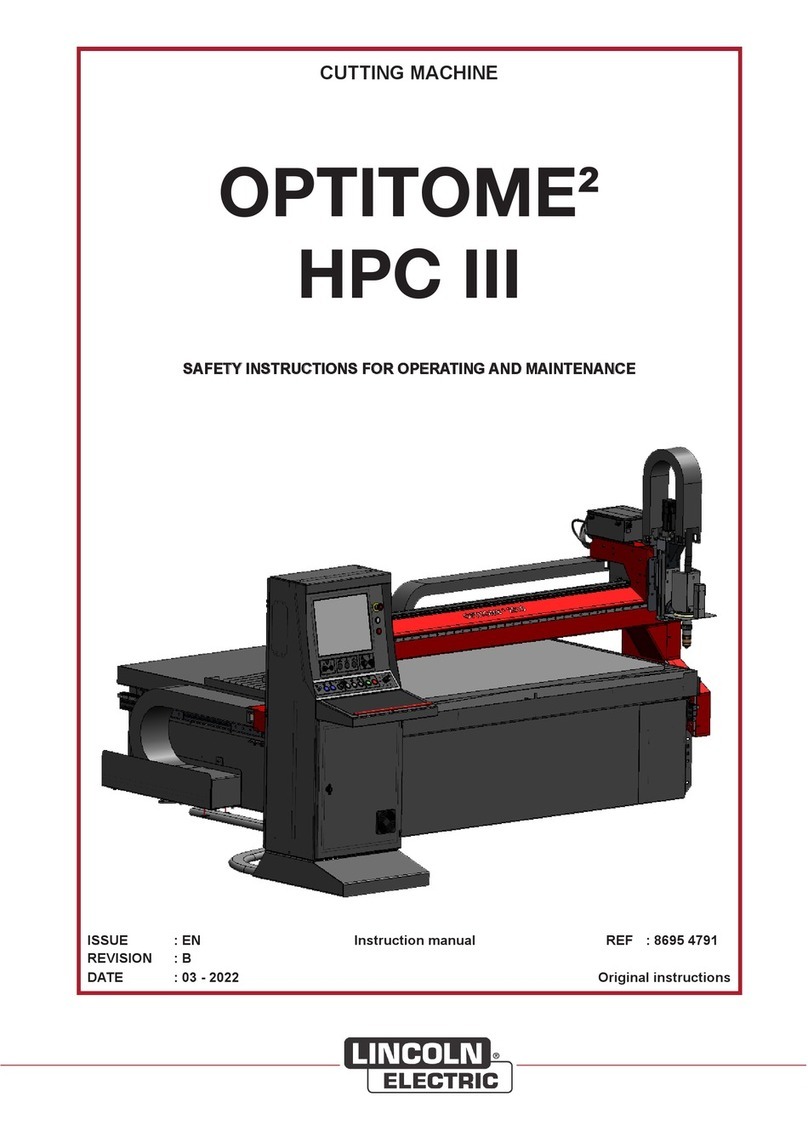

OPTITOME HPC 2 I

CONTENTS

A - IDENTIFICATION.........................................................................................................................1

B - SAFETY INSTRUCTIONS............................................................................................................2

1 - AIRBORNE NOISE .............................................................................................................2

2 - CONSIGNES PARTICULIERES DE SECURITE................................................................3

3 - LAYOUT..............................................................................................................................6

C - DESCRIPTION .............................................................................................................................8

1 - DESCRIPTION....................................................................................................................8

2 - GENERAL...........................................................................................................................9

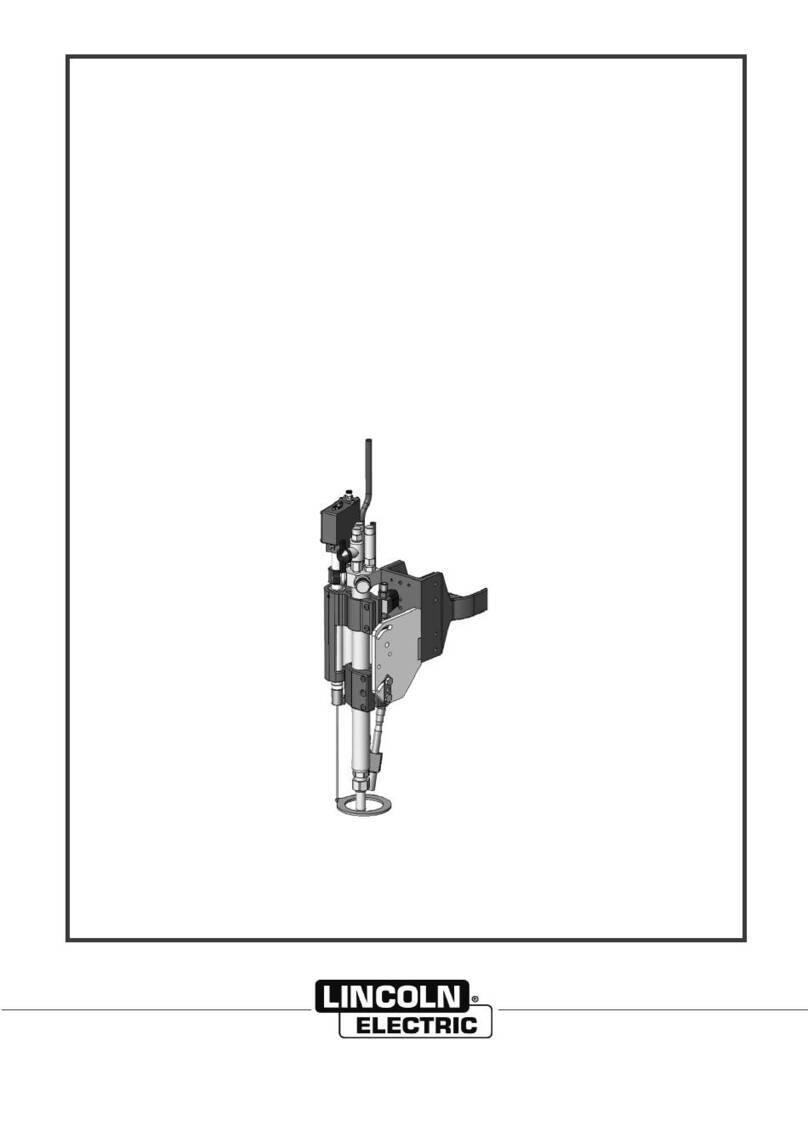

3 - MECHANICAL ASSEMBLY................................................................................................10

4 - CUTTING TABLE................................................................................................................11

5 - TRANSVERSE CARRIAGE................................................................................................12

6 - POWER SYSTEMS ............................................................................................................12

7 - CONSOLE...........................................................................................................................13

8 - LIMIT OF SUPPLY..............................................................................................................14

D - ASSEMBLY AND INSTALLATION..............................................................................................15

1 - CONDITIONS OF INSTALLATION.....................................................................................15

2 - FLOOR PREPARATION.....................................................................................................16

3 - PUTTING IN PLACE OPTITOME 2040...............................................................................16

4 - PUTTING IN PLACE OPTITOME 1530...............................................................................23

5 - CONNECTING THE ENERGY SUPPLIES.........................................................................25

E - OPERATOR MANUAL.................................................................................................................27

1 - DESCRIPTION OF CONTROLS.........................................................................................27

2 - STARTING UP THE MACHINE..........................................................................................28

3 - STOPPING THE MACHINE................................................................................................30

F - MAINTENANCE............................................................................................................................31

1 - SERVICING.........................................................................................................................31

2 - TROUBLESHOOTING........................................................................................................33

3 - SPARE PARTS...................................................................................................................36

PERSONAL NOTES ..........................................................................................................................42