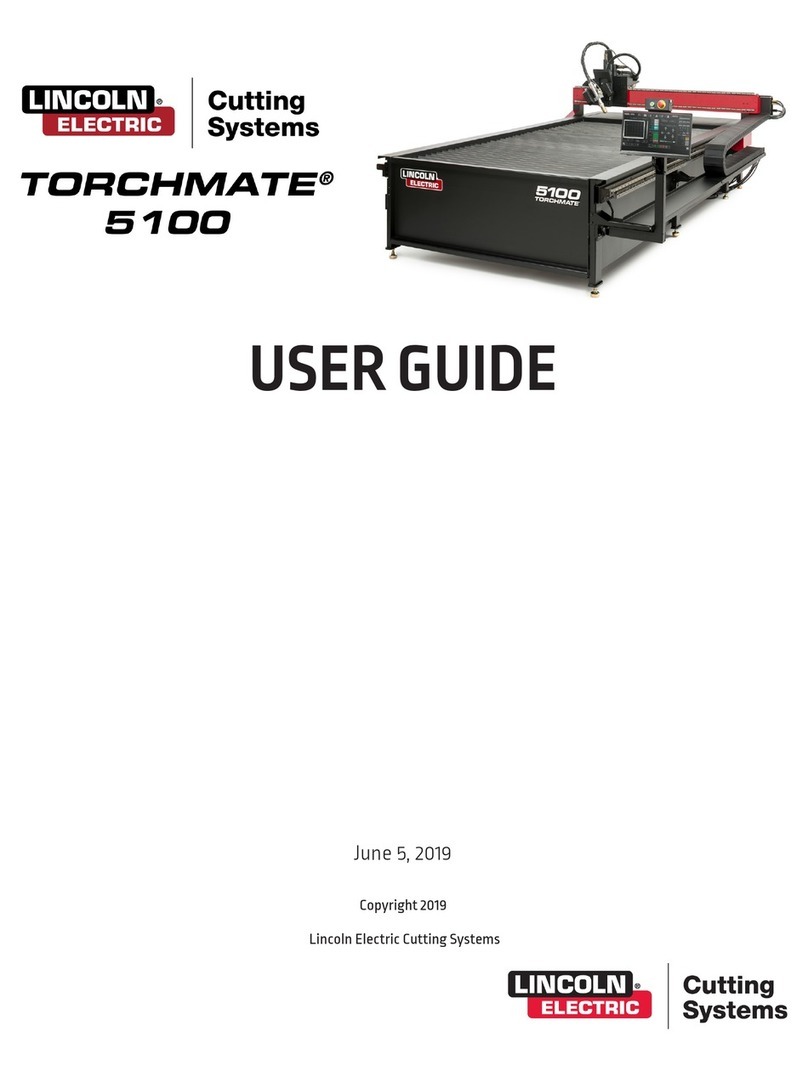

7Site Preparation Guide

Input Power

• 120V / 1Ph / 15A / 60Hz (table and computer)

• 380-600V / 3Ph / 50-60Hz (Plasma Power Supply specic)

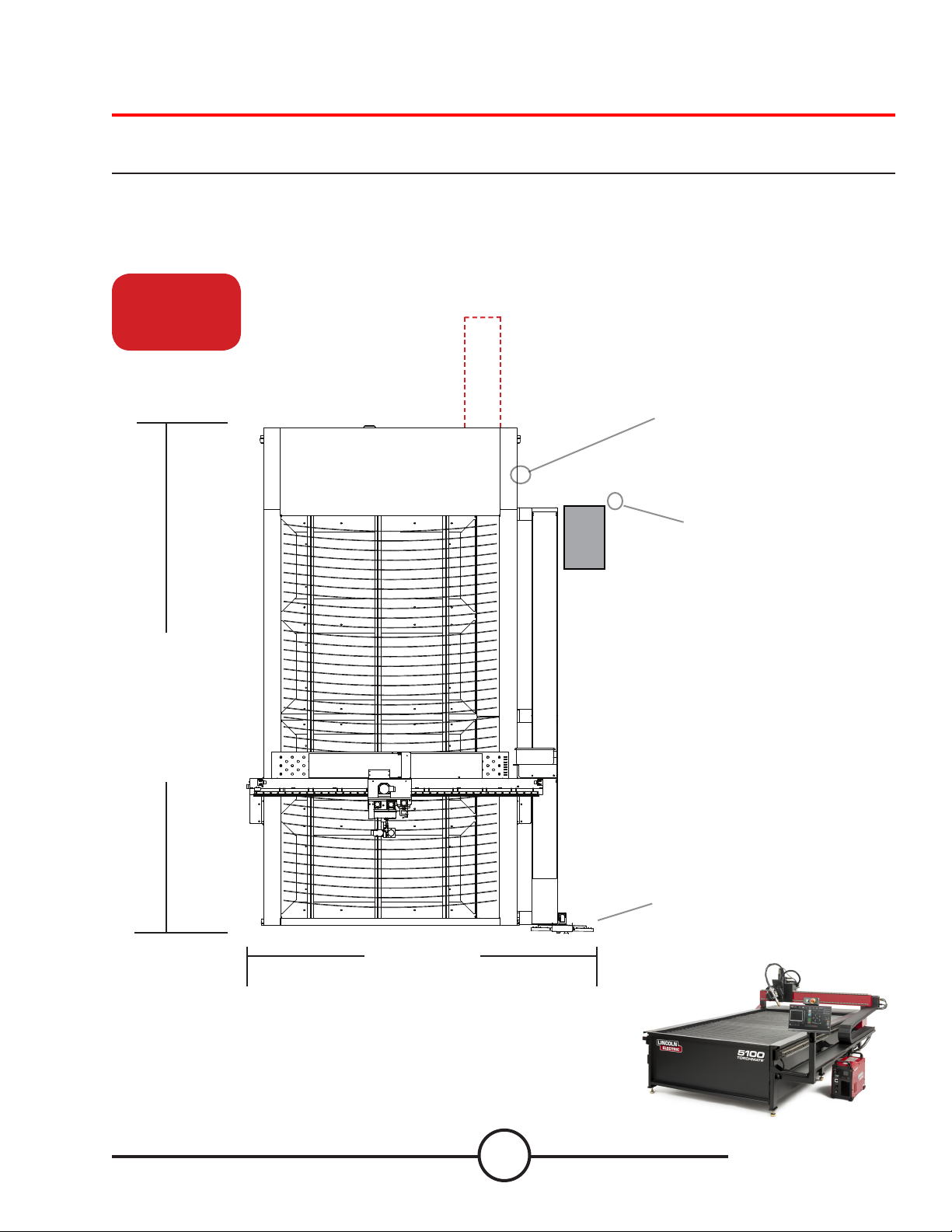

Machine Size

• 60˝ x 120” (1524mm x 3048mm) Cutting Area

• 113.5˝ x 167” (2895.6mm x 4241.8mm) Footprint

Traverse Speed

• 1,500 ipm (0.635 mps)

Cut Speed

• Up to 1500 ipm

Plate Capacity

• Holds Up To 4” (102mm) 5’x10’ (1524mm x 3048mm) Mild Steel

Weight

• 6,600 lbs

Operating Temperature

• 32-104° Fahrenheit (0-40° Celsius)

Motors

• Servo Motors Fitted with Rotary Glass Encoders

Drive System

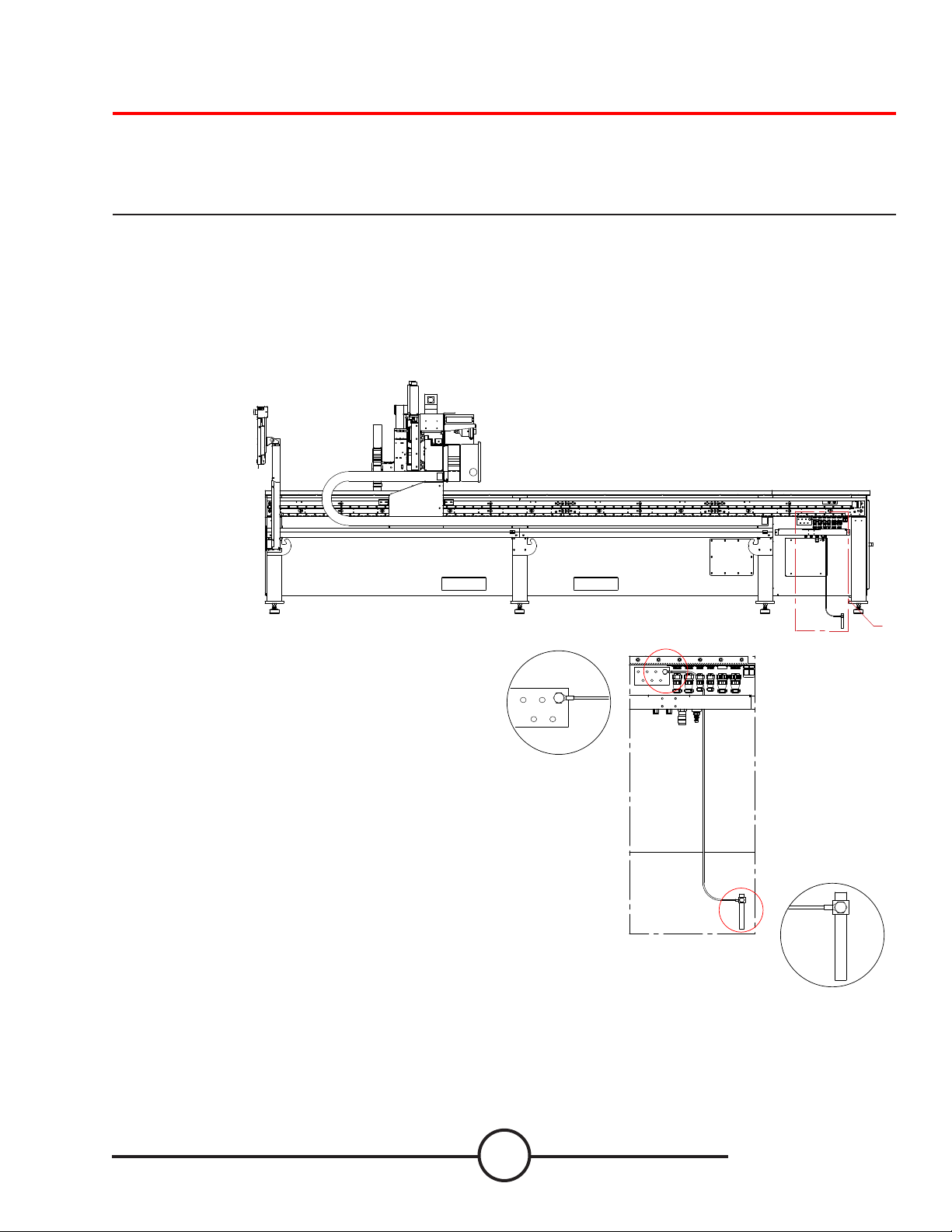

• Helical Gear Rack and Hardened Pinion with Lubrication

System

Linear Guidance

• Prole Linear Rail

Acceleration Rate

• 0.08g (0.06g Bevel)

Deceleration Rate

• 0.08g (0.06g Bevel)

Input Pneumatics

• Minimum 115PSI Supply Pressure

• Volume - 7 SCFM (420 SCFH) @ 90PSI

Height Control

• Ohmic Sensing

• Automatic Torch Height Control

• 6.75” Z-axis Travel

Bevel Capabilities

• +/-45° Rotation (dependent on material thickness and power

supply conguration)

Software

• Easy-To-Use Lincoln Electric User Interface

• CAM with Irregular Part Nesting

• Popular Shape Library

Fume Extraction (Optional Accessory)

• 61,801 ft3/hr or 1,750 m3/hr minimum

• Automatic Filter Cleaning, Pressure Controlled

Downdraft Conguration

• Multiple Zones Controlled By Motion Controller

Safety

• Dual-Channel Safety System Supporting Emergency Stop

Switch

• Safety System Extended To External Peripherals

• External Drive Power On Switch

Warranty

• *1 Year Warranty

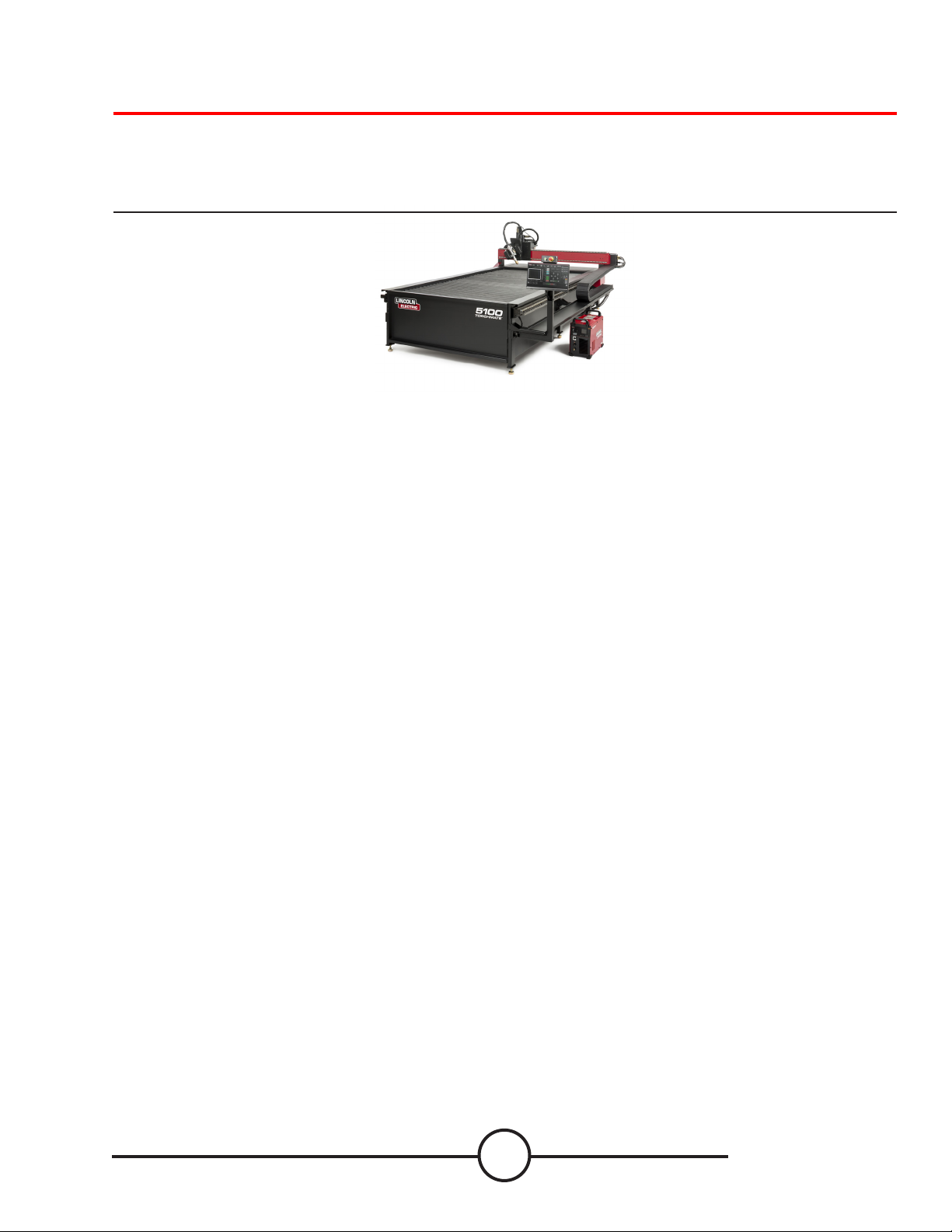

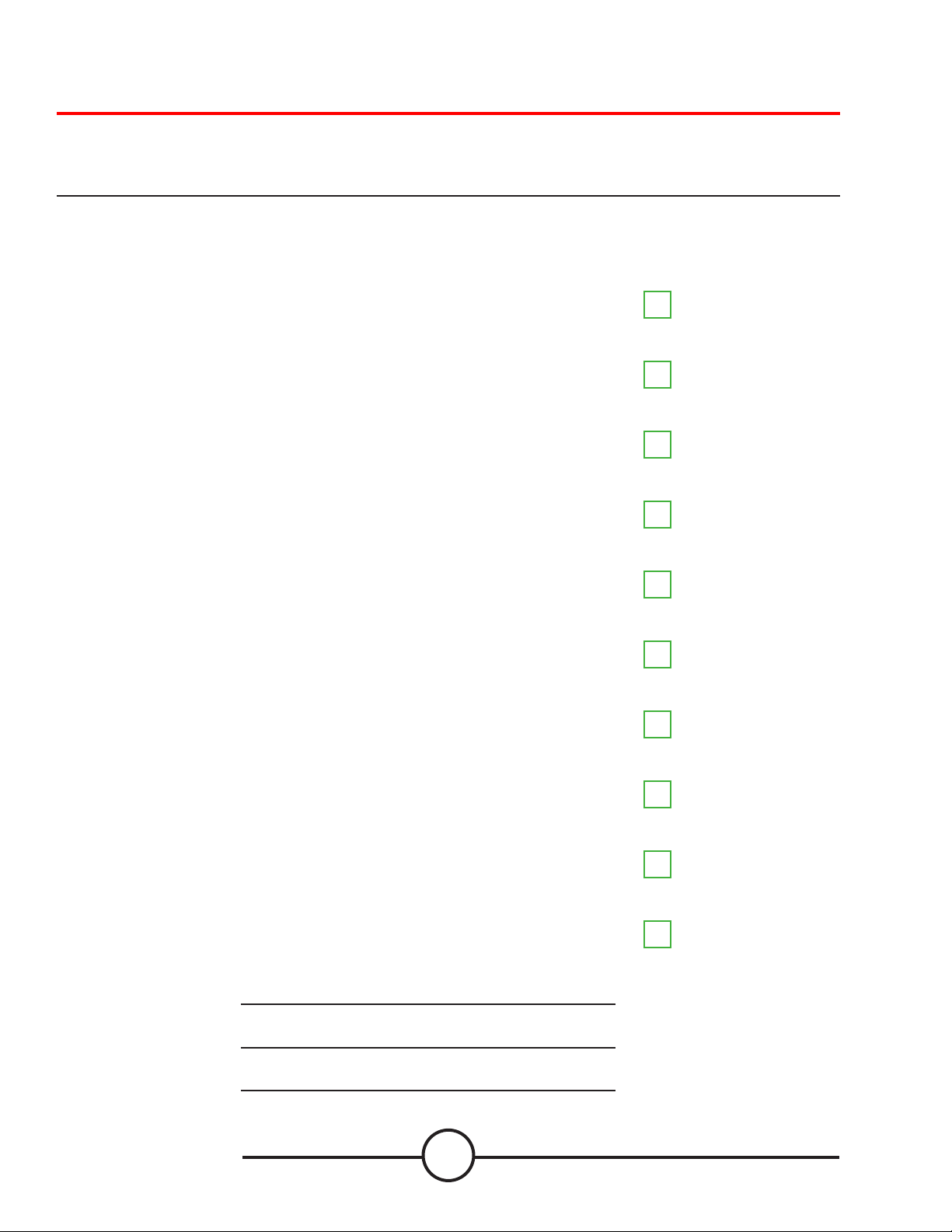

TORCHMATE 5100 CNC PLASMA SYSTEMS FlexCut 125 FlexCut 200 Spirit ii 275 Spirit ii 400

PRODUCTION CUTTING CAPACITY

Mild Steel 1” (25mm) 1.25” 1.5” (38mm) 2” (50mm)

Stainless Steel 3/4”(20mm) 3/4”(20mm) 1” (25mm) 1.5” (38mm)

Aluminum 5/8”(16mm) 3/4”(20mm) 3/4” (20mm) 1.5” (38mm)

CUTTING SPEED @ RATED OUTPUT CURRENT

1/4” MS 210 ipm @125A 200 ipm @200A 230 ipm @200A 230 ipm @ 200A

1/2” MS 88 ipm @125A 110 ipm @200A 125 ipm @ 275A 160 ipm @ 400A

1” MS 32 ipm @125A 40 ipm @200A 65 ipm @275A 85 ipm @ 400A

PROCESS AMPS 20A - 125A 15A - 200A 30A - 275A 30A - 400A

CUTTING GAS

Mild Steel Air / Air Air / Air Oxygen / Air Oxygen / Air Oxygen / Oxygen

Stainless Steel Air / Air Nitrogen Air / Air Nitrogen Air / Air - Nitrogen H17 / Nitrogen Nitrogen / Air

Aluminum Air / Air Air / Air Air / Nitrogen Nitrogen Air

INPUT VOLTAGE 380/400/415V3Ph50/60Hz 380/460/575V3Ph50/60Hz 380V 3Ph 50/60Hz | 400V 3Ph 50/60 Hz

460V 3Ph 50/60Hz 400V3Ph 50Hz (CE) 415V 3Ph 50/60Hz | 440V 3Ph 50/60Hz

575V 3Ph 50/60Hz 480V 3Ph 50/60Hz | 600V 3Ph 50/60 Hz

Table Specications