THE LINC LN ELECTRIC C MPANY®

22801 St. Clair Ave., Cleveland, H 44117-1199 • 216.481.8100 • www.lincolnelectric.com

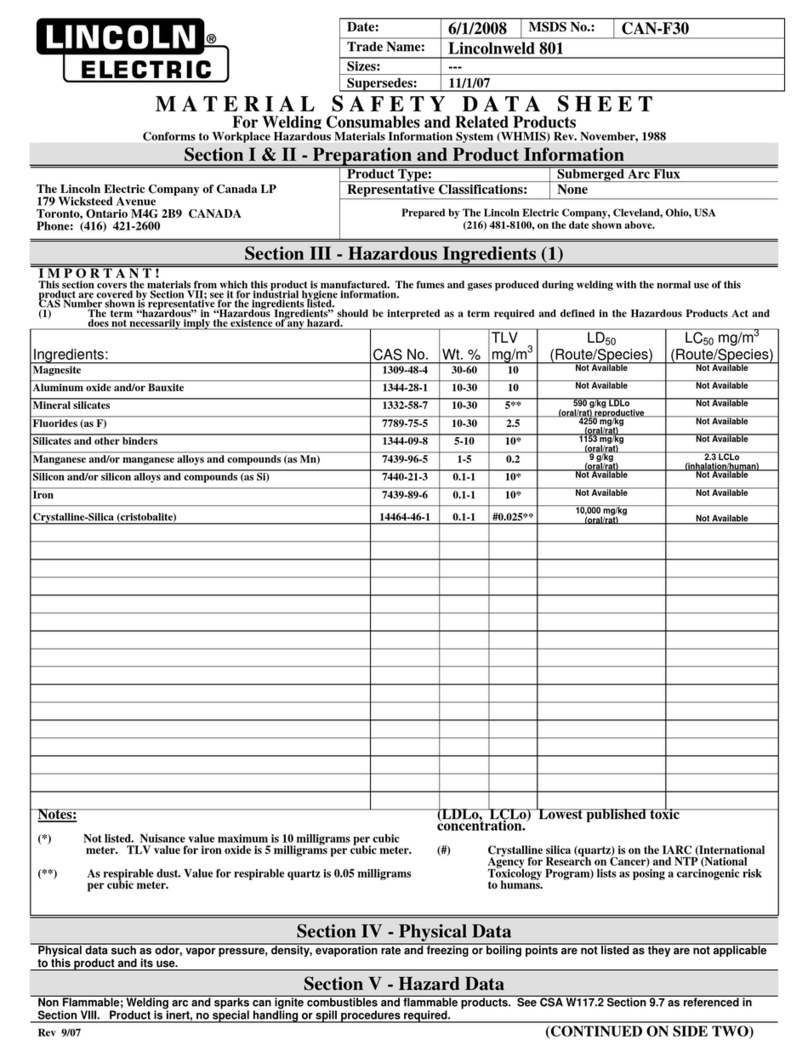

RECOMMENDED OPTIONS

GENERAL OPTIONS

Welding Cart

Full-featured cart is designed to

store and transport a welder, 80

cubic foot gas cylinder, welding

cables and accessories. Includes

an angled top shelf for easy

access to welder controls, a lower

tray for added storage space, a

sturdy handle and a convenient

cable wrap hanger.

rder K2275-1

Utility Cart

Heavy duty cart stores and trans-

ports welder, 150 cubic foot

shielding gas cylinder, welding

cables and accessories. Includes

stable platforms for welder and

gas bottle platform, lower tray for

added storage capacity and

adjustable height handle.

rder K520

Small Canvas Cover

Protect your welder when not in

use. Made from attractive red

canvas that is flame retardant,

mildew resistant and water repel-

lent. Includes a convenient side

pocket to hold your welding torch

or gun.

rder K2377-1

Spot Timer Kit

This timer allows you to set a

fixed weld time of up to 10 sec-

onds that is initiated when you

pull the gun trigger. Ideal for

making consistent spot welds on

thin sheet metal.

rder K2525-1

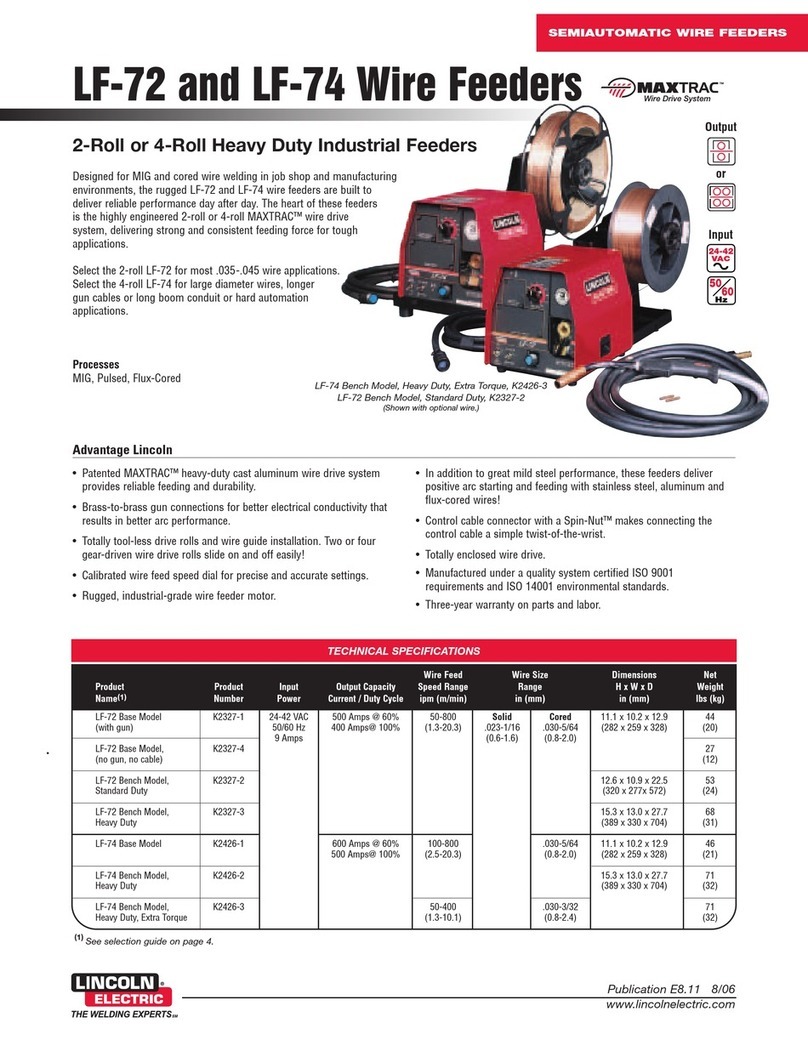

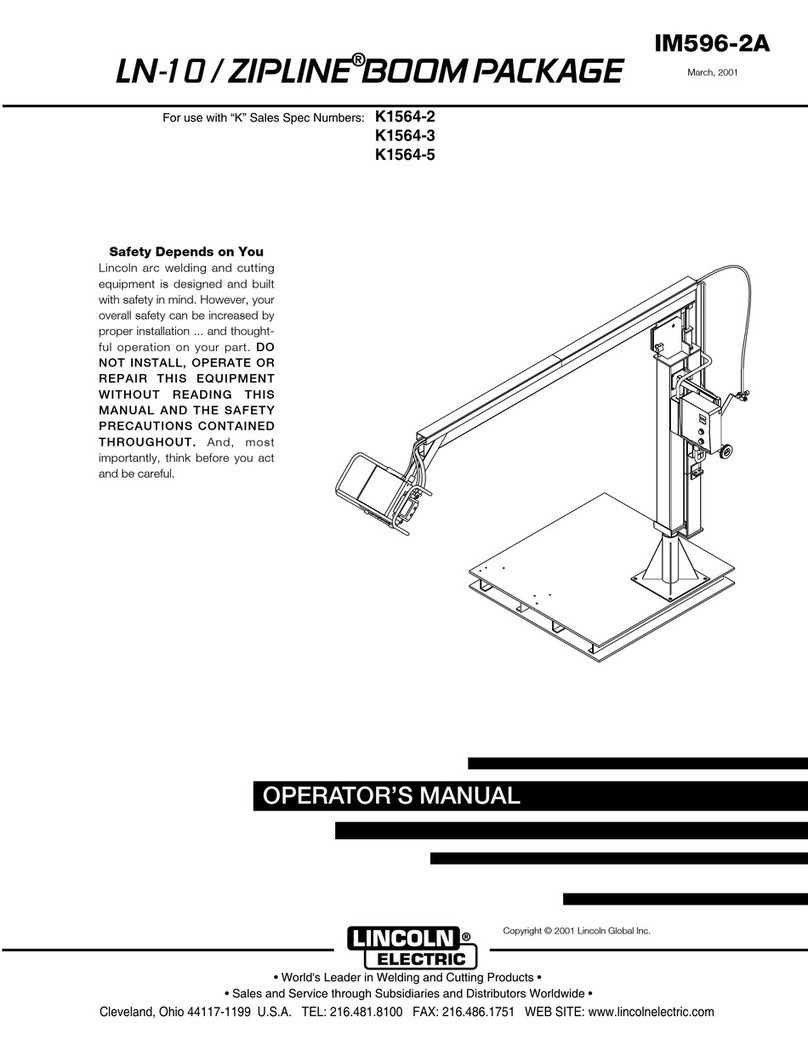

WIRE FEEDER OPTIONS

Magnum®100SG Spool Gun

Designed to easily feed 4" (102

mm) diameter 1 lb. (0.45 kg)

spools of .030" (0.8 mm) or .035"

(0.9 mm) diameter SuperGlaze®

aluminum MIG wire. Includes gun,

adapter kit, .035" (0.9 mm) contact

tips (qty. 3), gas nozzle, and a 1 lb.

(0.45 kg) spool of SuperGlaze®

4043 .035" (0.9 mm) MIG wire.

Packaged in a convenient carrying

case.

rder K2532-1

.045" (1.1 mm) Innershield®Kit

Includes everything required to

weld with .045" (1.1 mm)

Innershield®self-shielded flux-

cored wire. Includes an .035"-

.045" (0.9-1.1 mm) Magnum®100L

gun liner, a .045" (1.1 mm) contact

tip, a gasless nozzle, knurled drive

roll, .045" (1.1 mm) inner wire

guide and a 10 lb. (4.5 kg) spool

of .045" (1.1 mm) Innershield®

NR®-212 wire.

rder K2528-1

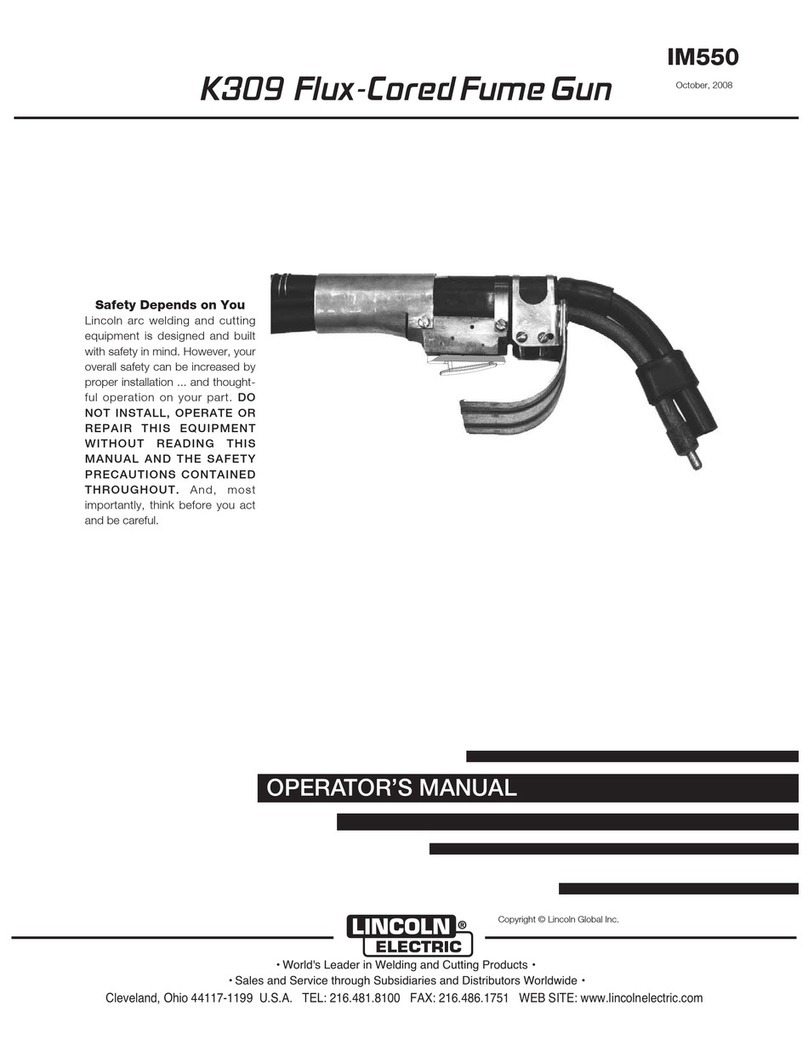

Welding Fume Extractors

Lincoln offers a wide variety

of welding fume extraction

environmental system solutions,

ranging from portable systems

easily wheeled around the shop

to shop-wide central systems

servicing many dedicated welding

stations.

Request Publication E13.40

C U S T O M E R A S S I S T A N C E P O L I C Y

The business of The Lincoln Electric Company®is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. ur challenge is to meet the needs of our customers and to exceed

their expectations. n occasion, purchasers may ask Lincoln Electric®for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time.

Lincoln Electric®is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of

fitness for any customer’s particular purpose, with respect to such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information

or advice once it has been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric®is a responsible manufacturer, but the selection and use of specific products sold by Lincoln Electric®is solely within the control of, and remains the sole responsibility of the customer. Many variables

beyond the control of Lincoln Electric®affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

PR DUCT DESCRIPTI N RDER NUMBER QUANTITY PRICE

P WER MIG®180C – 208-230/1/60 K2473-1

Recommended General ptions

2-Year Extended Warranty - Power MIG®180C X2473

Welding Cart K2275-1

Utility Cart K520

Small Canvas Cover K2377-1

Fume Extraction System See Bulletin E13.40

Recommended Wire Feeder ptions

Magnum®100SG Spool Gun K2532-1

.045" (1.1 mm) Innershield®Kit K2528-1

Spot Timer Kit K2525-1

T TAL:

POWER MIG®180C ORDER FORM