English English

6

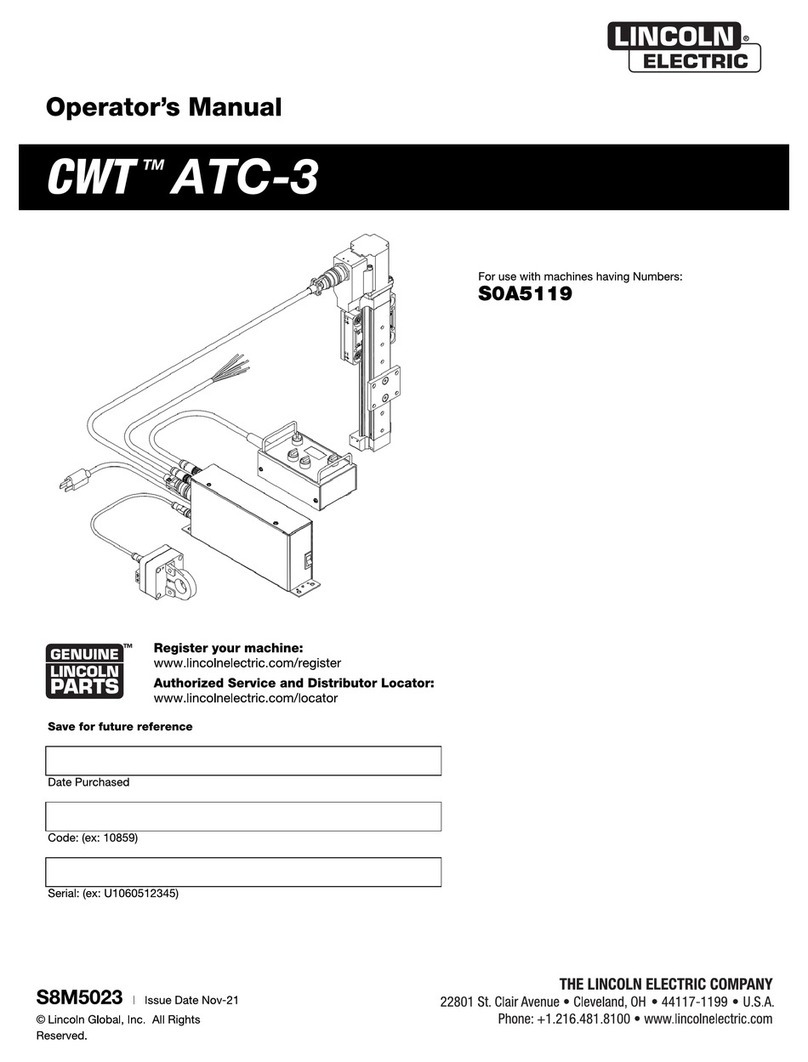

DESIGN FEATURES

HARDWARE OVERVIEW:

Virtual Welding Machine, including:

Monitor

Coupon Drawer (back drawer)

VR GMAW/FCAW Gun

VR SMAW Device

VR GMAW/FCAW Gun Holder

VR SMAW Device Holder

VR Helmet w/Face Mounted Display (FMD)

Arm

Speakers

Five VR Coupons Flat Plate

T-Joint

Groove Joint

2” Pipe XXS

6” Pipe Schedule 40

Stand, including:

Post

Table

Pins

Base

Weights

HARDWARE UNCRATING:

TOOLS NEEDED

3/8” (9.5 mm) Wrench

3/16” (4.8 mm) Allen Wrench

Phillips Screwdriver

1. Decide on a location for your unit.

NOTE: The system requires approximately 8’ L x 8’ D

x 8’ H (2.4 m L x 2.4 m D x 2.4 m H) of space.

Keep at least 3 feet in all directions of both the

stand and VR weld machine free from

obstruction. In addition, be conscious of where

you are placing the unit to avoid magnetic fields,

conductive, and high frequency objects and

processes.

NOTE: Avoid setting up the VRTEX®360 near high

frequency TIG machines and power sources.

Having these types of objects in the area can

cause interference and result in increased jitter

and/or distortion in the motion tracking.

For best results, do not install VRTEX®360

machine in the welding lab. Electrical

interference from power lines, though generally

small, can be present. Therefore all electrical

power or lighting wiring within 50 feet of the

welding area shall be enclosed in grounded

rigid metallic conduit. In the event the VRTEX®

360 is affected by interference, it is the user's

responsibility to take steps to isolate and/or

eliminate the interference.

An uninterruptible power supply (UPS) may be

required for the protection of the system from

power irregularities or disruption.

It is strongly recommended that a single or

Multi-Outlet surge protector be used to protect

the machine from any unwanted voltages above

a safe threshold.

MULTIPLE SYSTEM INSTALLATIONS

If multiple systems are required to operate together in

one location, a unique frequency transmitter can be

installed during the manufacturing process at Lincoln

Electric to reduce potential interference between

systems. K3962-1 systems have a standard frequency

source installed. K3962-2 systems have an alternate

frequency source installed. For multiple system

installations, alternate the K3962-1 and K3962-2

systems for best operation:

For Example: If 8 systems are to be installed in the VR

welding lab, the standard and alternate frequencies

should be positioned as seen below.

K3962-1 K3962-2 K3962-1 K3962-2

K3962-2 K3962-1 K3962-2 K3962-1

2. Using the 3/8” (9.5 mm) wrench, remove the screws

from the upper and lower front panels on the

shipping crate.