Page 8 of 16

User Manual

Operating Instructions

Subject to modifications

4.2EN-18005-C10

LINCOLN GmbH • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Installation

Safety Instructions

1 013A94

CAUTION!

Never exceed the centralized lubrication

system’s maximum operat ing pressure of

300 bar.

Make sure to disconnect the

pump/machine or system from the pow er

supply before carrying out any mainte-

nance or disassembly works.

Check compatibility of synthetic lubricants

with the material of the metering devices

and other system components before use.

Required Tools

For the installation o f the injectors ring wrenches (SW 24)

are required.

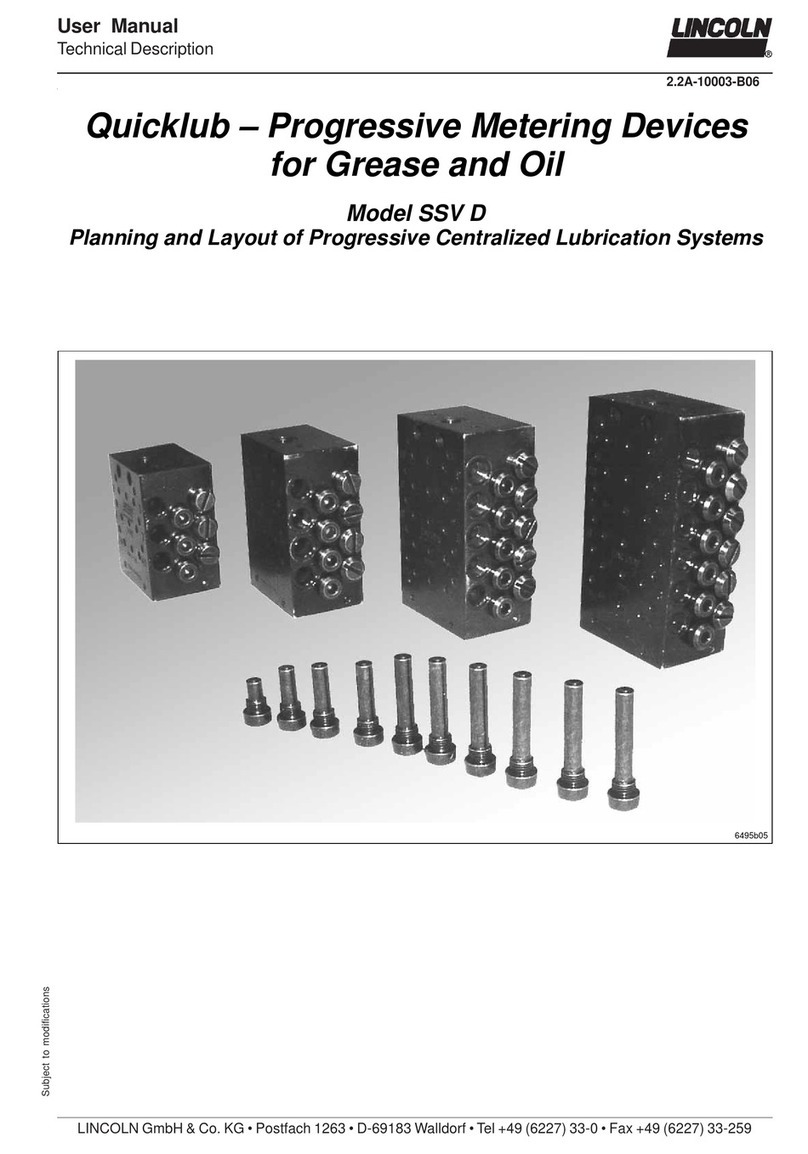

Attachment of Injectors to Divider Bar

For connection to the divider bar the injectors are pro-

vided with a conne ction thre ad G 3/8“.

If a lube point requires an increased amount o f lubricant,

the outlets of two or more injecto rs of a subassembly (di-

vider bar) can be combined externally by means of tube

adapters.

Each connection re quires one tube adapter.

On both faces the divider bars dispose of a female thread

of G3/8“.

If required, fittings for connection of the injectors must be

ordered separately.

The divider bars dispose of faste ning bores Ø 10. 5mm

(see Fig. 2).

The QSL metering devices can be at tached in any posi-

tion. However, make sure to provide free access to the

visu al f unction control.

6445b 05

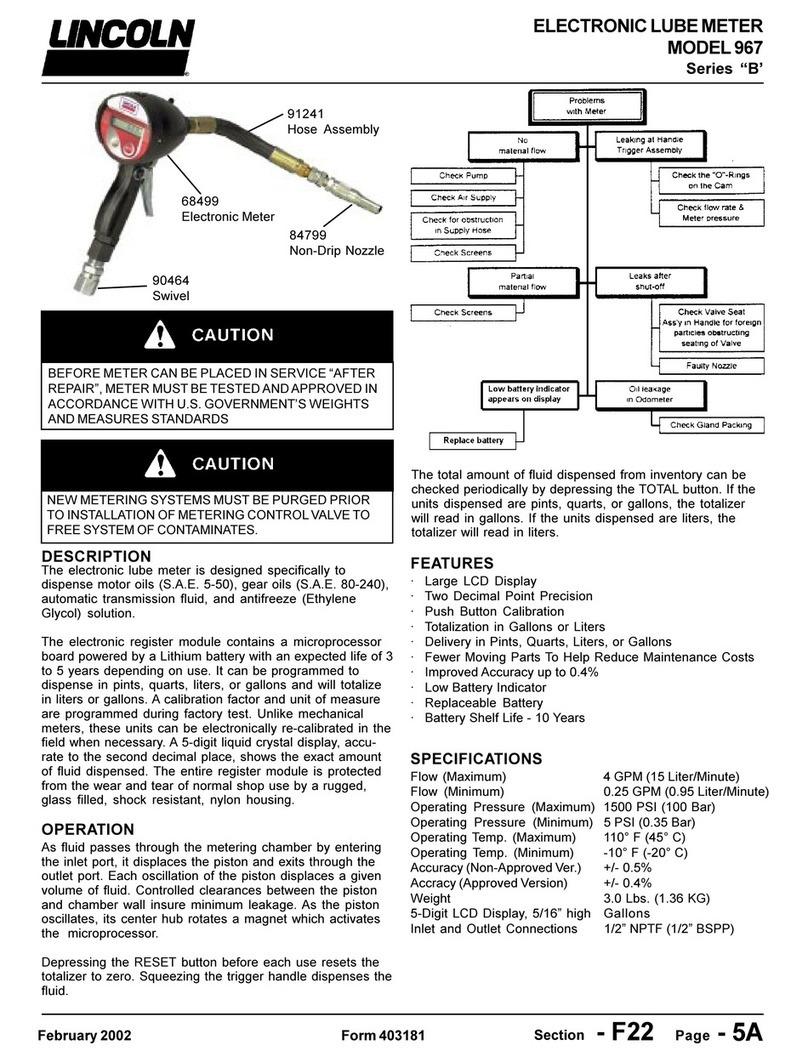

CAUTION – DANGER OF SQUEEZING!

During the metering procedure, the control

pin is pressed out of the injector for func-

tion control purposes 1.1 (fig. 4).

Between the extracting control pin and the

cover provided by the owner of the system

there exists the danger of squeezing!

Make sure to provide sufficient space

between the cover and the injector.

For counterpressures exceeding ≥100 bar check valves

must be used.

Place of attachment

(see plan & instructions by the machine m anufacturer)

Assignm ent of lube points to the injectors

(see plan & instructions by the machine m anufacturer)

Furt her make sure th at the place of attachment of the

QSL metering device allows for routing the lines (main re-

spectively feed lines) in such way that they cannot be

damaged and do not disturb the function of the machin e.

Consid er the m aximum ambient temperature f or machines

with heat emission.

Assembly and Disassembly of Injectors

A injector is screwed to the divider bar wit h a tigh tening

torque o f 40 Nm.

When reassembling, consider the tightening torque of the

hollow screw and make sure the sealing rings are seated

correctly on the divider bar.

After replacing of an injector:

- Ve nt QSL metering device an d respective section of line

(see chapter "Start-up", page 12)

6 001a0 2

IMPORTANT NOTE

Observe tightening torques of single com-

ponents during installation (see Fig. 2).

Also observe installation instructions for

the tubing and fastening material of the

centralized lubrication system (see ma-

chine manufacturer’s plan and parts list).

The centralized lubrication lines have to comply with the

individual o peration requirements as regards material

quality, pressure resistance, nominal width and length,

and have to be adap ted to the centralize d lubrication sys-

tem.

- Route and mount lines pro fessionally.

- Mount tube fittings firmly and leak-proof.

Observe installation instruction of th e manufacturer of

the fittings.

- Be fore installing tube lines an d hoses, make sure that

inside they are free fro m foreign particles. Steel tubes

mu st b e rust-f re e.

- Cut steel tubes to size with pipe cutter. Tube must be

cut rectangular and free of burrs.

- Observe bending radius of ste el pipes a nd flexible lines.

- Mount pipes with clamps vibration-free and safe against

break-off.

Acces sories

6 001a0 2

NOTE

Instead of the planned inje ctors a divider

bar can also be equipped with a closure kit.

(Part no. 554-34387-1).