P 5 f 24

Subject to modifications

User Manual

Operating Instructions

2.2EN-20001-J11

Regulations for Prevention of Accidents

To prevent accidents, observe all city, state and federal

safety regulations of the country in which the product will

be used.

Avoid the operation with

- unapproved parts.

- insufficient or contaminated lubricants.

Operation, Repair and Maintenance

Authorized and instructed personnel who are familiar with the

centralized lubrication systems should only perform repair.

Appropriate Use

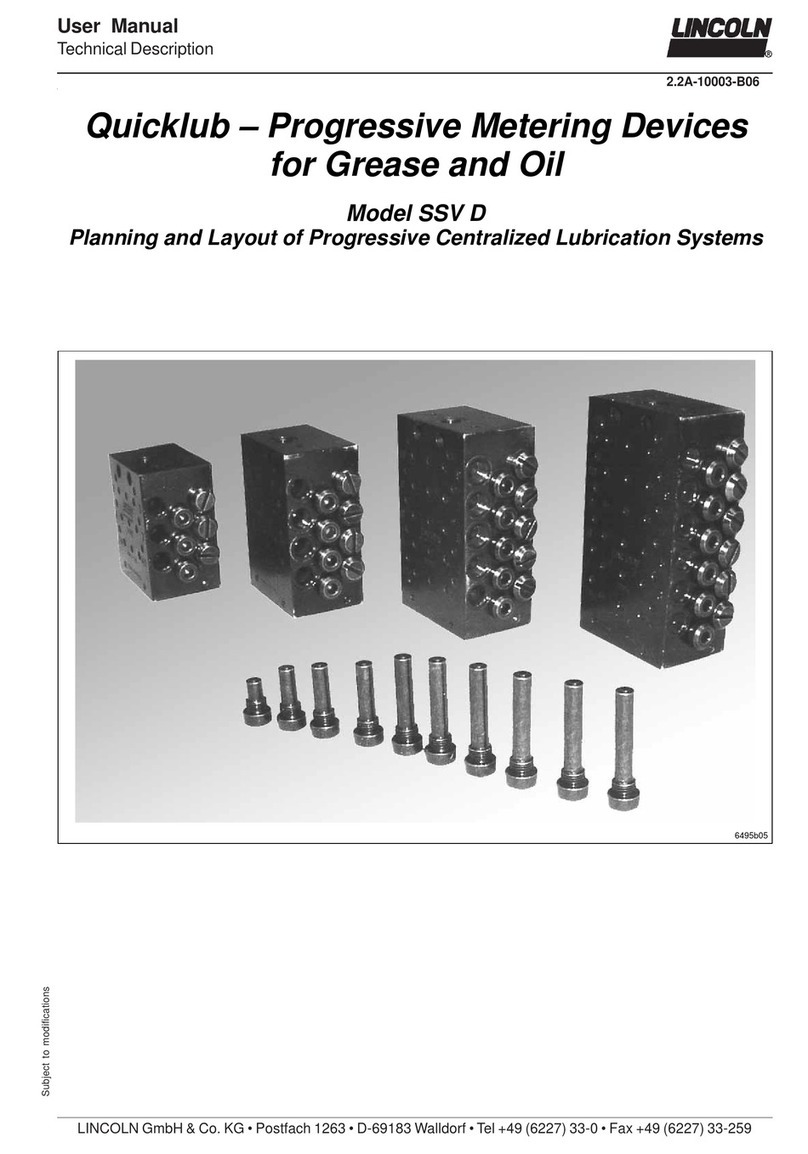

Use the SSV, SSV-E and SSV M lubricant metering devices

only for dispensing lubricants in centralized lubrication sys-

tems.

Suitable Lubricants

The progressive metering devices model SSV can be used

for dispensing

- mineral oils of at least 40 mm2/s (cST) or

- greases up to the penetration class NLGI 2

6001a02

IMPORTANT

It must nevertheless be ensured that the

oils or greases used do not alter their con-

sistency significantly in the course of time or

under the influence of temperature or

pressure.

General Safety Instructions

The progressive centralized lubrication system connected

to the Quicklub pump model 203 must always be secured

with a pressure relief valve.

Lincoln SSV, SSV-E and SSV M lubricant metering devices

are state of the art.

Incorrect use may result in bearing damage caused by

poor or over-lubrication.

Each outlet which will be used must be equipped with a

check valve.

In the case of the metering devices model SSV 6 to 12 or

SSV6-E to 12-E and SSVM 6 to 12 the outlets 1 and/or 2

must never be closed.

Unauthorized modifications or changes to an installed

system are not admissible. Any modification must be

subject to prior consultation with the manufacturer of the

lubrication system.

Use only original Lincoln spare parts (see Parts Catalogue)

or the parts approved by

Installation

Install the metering devices at a suitable location in ac-

cordance with the lubrication diagram.

It is recommended that the metering devices be installed in

such a way that the outlets are not close to the chassis or

the attaching plate. This will facilitate troubleshooting in the

case the system is blocked.

The main metering devices with indicator pin must be

installed in such a way that the indicator pin is easily visible.

When the push-in type fittings are used, note the follow-

ing:

For the metering device inlet use only push-in type

fittings (R 1/8) with reinforced collar and sealing ring.

For the outlet tube fittings of the SSV divider valve

(M 10x1) depending on the design of the lubricant line, for

example

- high-pressure plastic hose (Ø 4.1 x 2.3) use valve bodies

with reinforced collar only, or,

- pressure plastic tube (Ø 6 x 1.5) use valve bodies with

knurled collar only

For the outlet fittings of the SSV M divider divider valve

(M 8x1) pressure plastic tube (Ø 4 x 1) use valve bodies

with knurled collar only.

6001a02

NOTE

In the case of construction machines or

agricultural machines use high pressure

plastic hoses for the lubricant feet lines. In

such cases the outlet fittings of the sec-

ondary metering devices and the connec-

tion fittings to the lubricant points must

have a reinforced collet.

8VHRQO\WKHPDLQDQGIHHGOLQHVVSHFLILHGE\6.)DQG

DGKHUHWRWKHVSHFLILHGV\VWHPSUHVVXUHV.

1013A94

CAUTION!

Danger of injury in the case of serious

corrosion of metering device surfaces:

An increasing corrosion of the surfaces will

cause the balls pressed in to lose their hold.

Under pressure, they may suddenly burst

out and cause injuries.

For applications in corrosive environments,

use metering devices in stainless steel

version only.

Safety Instructions