SDGx50 Flow meter compressed air

2

Contents

1 Preliminary note ............................................................. 4

1.1 Symbols used.......................................................... 4

1.2 Warnings used ......................................................... 4

2 Safety instructions............................................................ 5

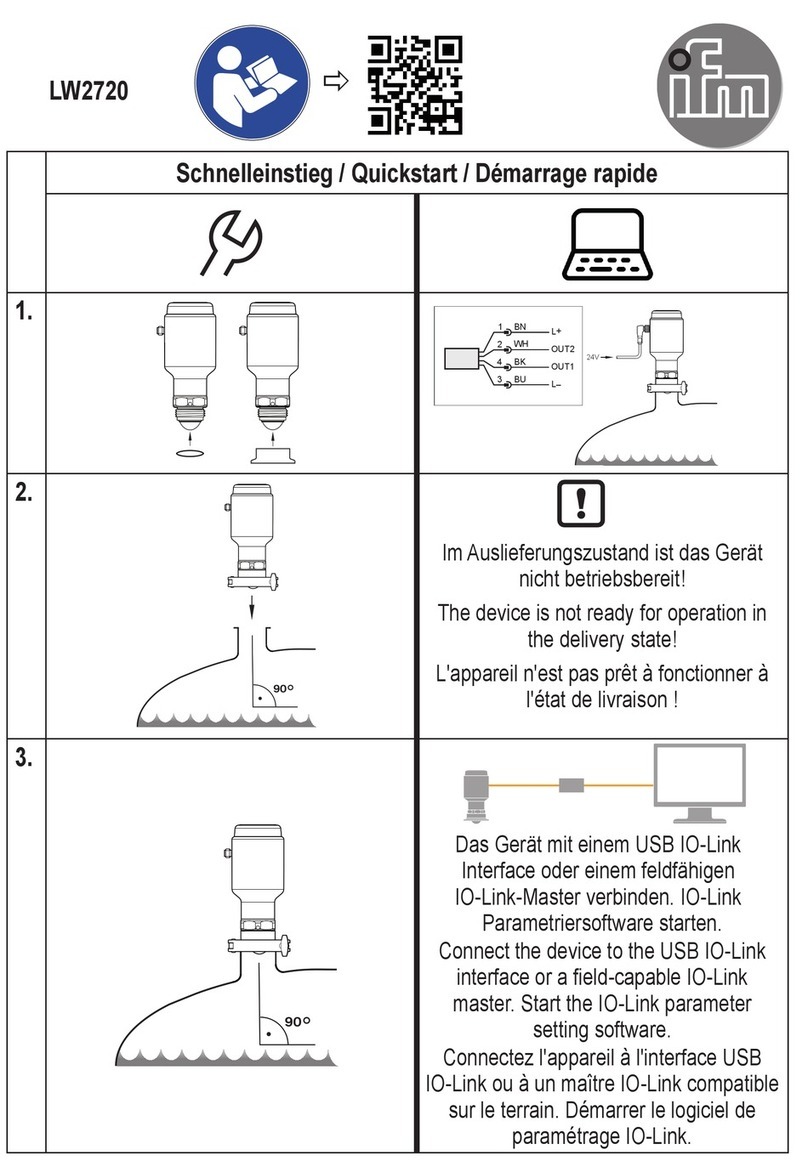

3 Getting started .............................................................. 6

3.1 Device function with factory setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Intended use................................................................ 7

4.1 Application area ........................................................ 7

5 Function ................................................................... 8

5.1 Output OUT1 selection options............................................. 8

5.2 Output OUT2 selection options............................................. 8

5.3 Switching output........................................................ 8

5.4 Analogue output........................................................ 9

5.5 Consumed quantity monitoring (totaliser function). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.5.1 Totaliser reset...................................................... 10

5.5.2 Consumed quantity monitoring via pulse signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.5.3 Consumed quantity monitoring via switching signal . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.6 Measured value damping................................................. 11

5.7 Low flow cut-off......................................................... 11

5.8 Simulation............................................................. 11

5.9 Display colour setting .................................................... 12

5.10 IO-Link ............................................................... 12

5.10.1 Additional functions via IO-Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Mounting................................................................... 14

6.1 Installation location...................................................... 14

6.2 Interference............................................................ 14

6.3 Orientation ............................................................ 15

6.4 Process connection...................................................... 15

6.5 Inserting the sensor into the pipe section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Electrical connection.......................................................... 17

8 Operating and display elements................................................. 18

9 Menu...................................................................... 19

9.1 Menu overview......................................................... 19

9.1.1 Adjustable parameters ............................................... 19

9.2 Main menu and submenus ................................................ 21

10 Set-up..................................................................... 25

11 Parameter setting............................................................ 26

11.1 Parameter setting in general............................................... 26

11.2 Presets............................................................... 26

11.2.1 Process value for OUTx .............................................. 26

11.2.2 Standard unit of measurement ......................................... 27

11.3 Setting the output functions................................................ 27

11.3.1 Limit monitoring OUTx/ hysteresis function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.3.2 Limit monitoring OUTx/ window function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11.3.3 Analogue signal OUT2 ............................................... 27

11.3.4 Pulse signal OUTx .................................................. 27

11.3.5 Switching signal totaliser OUTx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

11.4 Totaliser reset.......................................................... 28

11.4.1 Manual reset....................................................... 28

11.4.2 Time-controlled reset ................................................ 28

11.4.3 Reset via external signal.............................................. 28

11.4.4 Switch off reset..................................................... 28

11.5 User settings (optional)................................................... 29

11.5.1 Standard display.................................................... 29

11.5.2 Standard unit of measurement ......................................... 29