Subject to modifications

LINCOLNGmbH • Postfach1263 • D-69183 Walldorf•Tel+49 (6227) 33-0 •Fax +49 (6227) 33-259

Page 3 of 32

User Manual

OperatingInstructions

2.1EN-38016-C09

Table of Contents

Page

Introduction

Explanation of Symbols Used ............................................ 4

User's Responsibility ......................................................... 4

Environmental Protection .................................................. 4

Service .............................................................................. 4

Safety instructions

Appropriate Use ................................................................ 5

Misuse ............................................................................... 5

Exclusion of Liability .................................................... 5

Regulations for Prevention of Accidents ............................ 5

General Safety Instructions ............................................... 5

Operation, Maintenance and Repair .................................. 5

Operation with bayonet plug ........................................ 6

Repair .......................................................................... 6

Disposal ....................................................................... 6

Installation ......................................................................... 6

Description

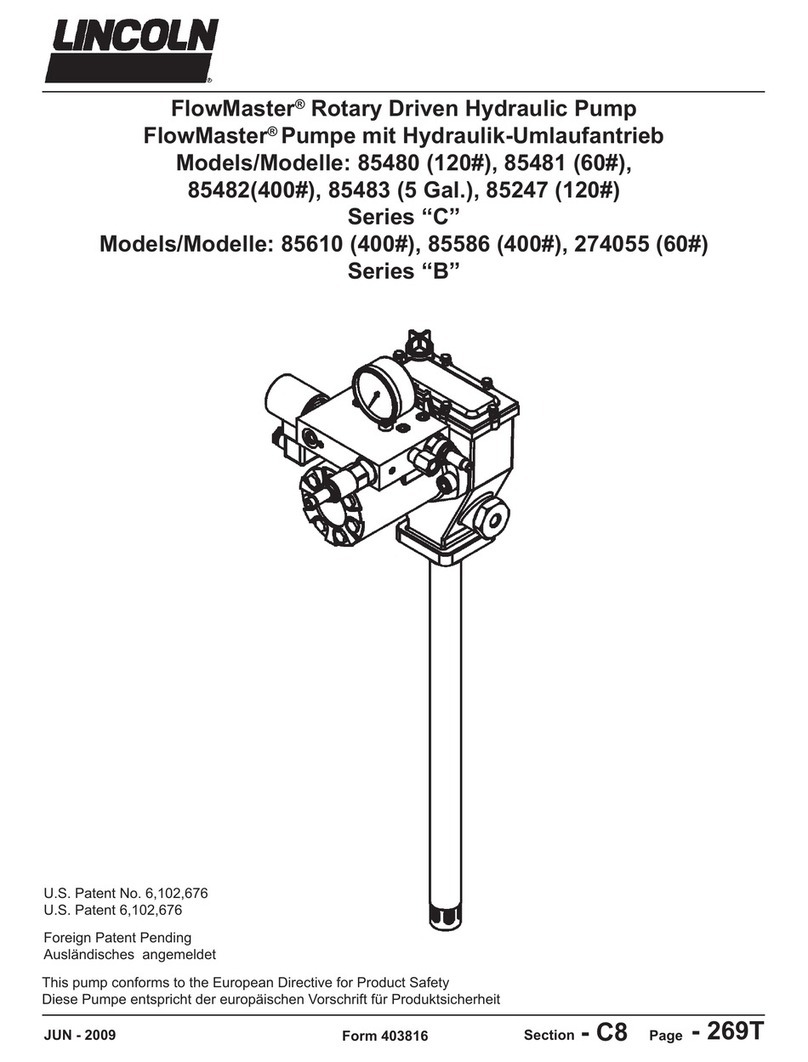

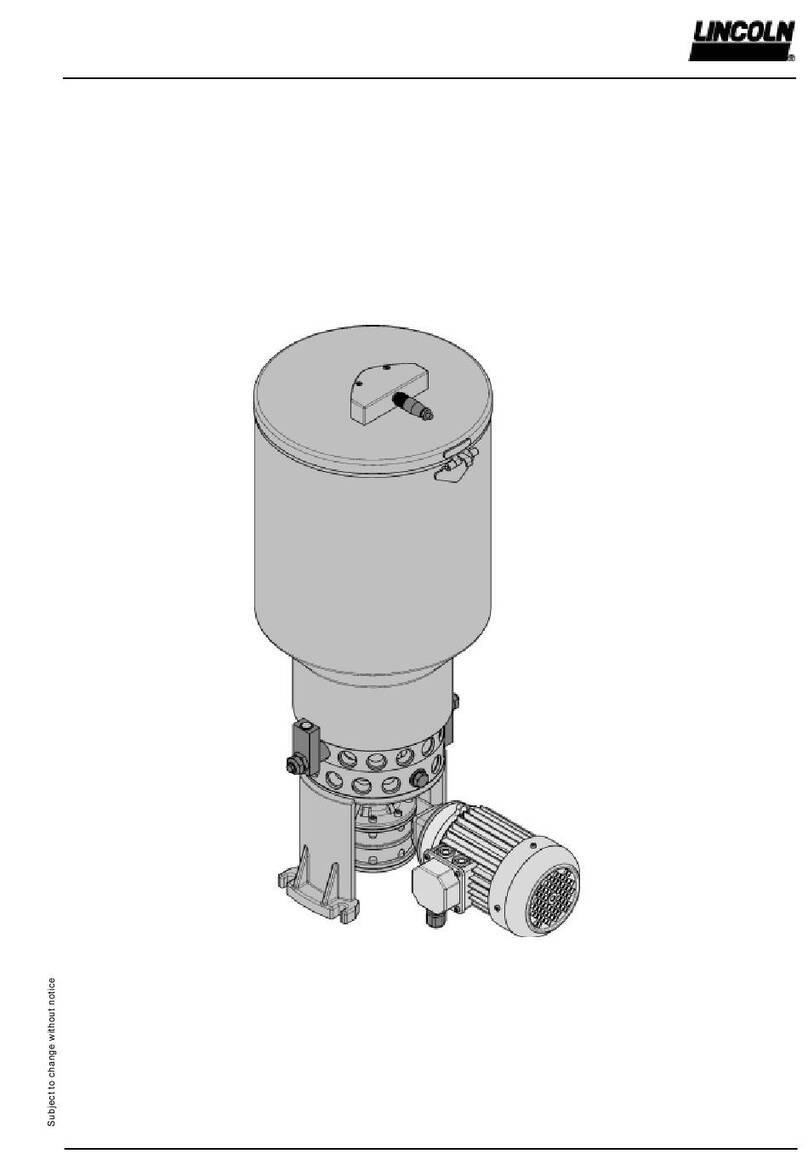

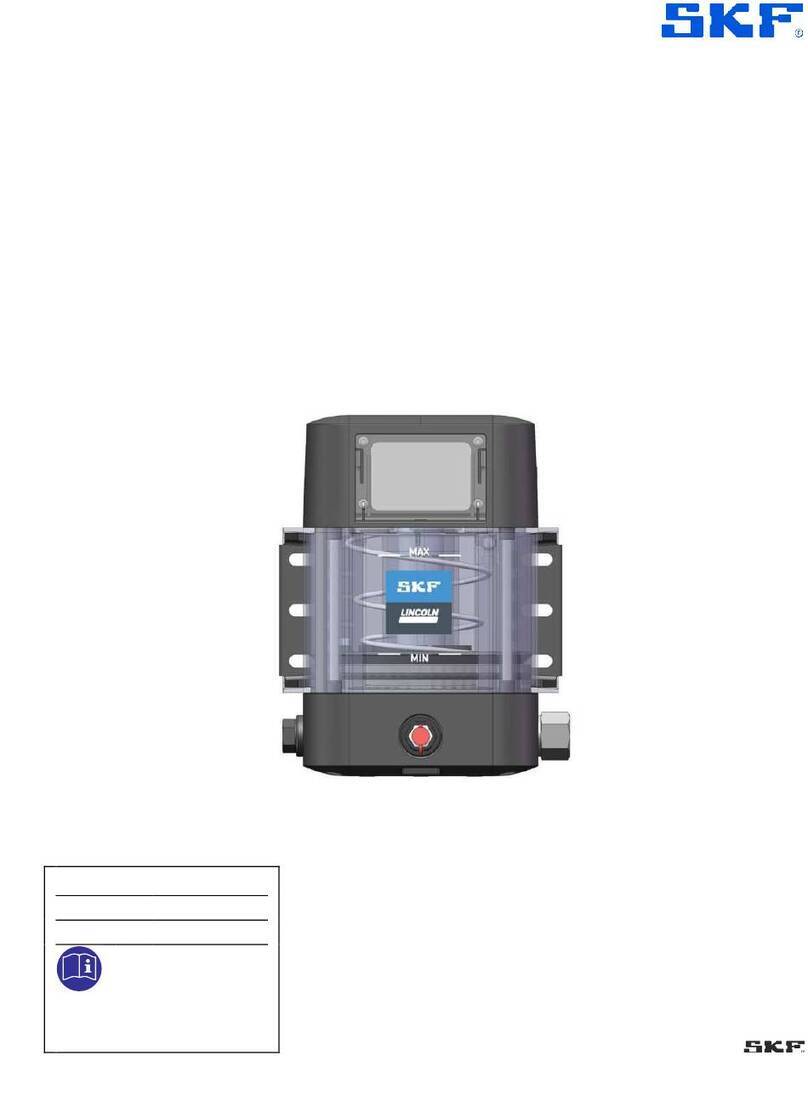

The Quicklub 203 central lubrication pump ........................ 7

Low-level control (option) ............................................. 7

Commissioning .................................................................. 7

Modeofoperation

Pump elements with fixed Lubricant output ....................... 8

Pump element B7 with bypass check valve ................. 9

Check valve ................................................................. 9

Arrangement of the pump elements ............................. 9

Pump element with adjustable lubricant output ................ 10

Adjustment of the lubricant output .............................. 10

Pressure relief valve ......................................................... 11

- without grease return ................................................ 11

- with grease return ..................................................... 11

Return line connection ...................................................... 12

Low-level control (option)

- for grease

Reservoir filled ............................................................ 12

When the reservoir is empty ....................................... 12

Electromagnetic switch ............................................... 13

- for oil

Float magnetic switch ................................................. 13

- Contact protection measures ......................................... 13

Page

Control p.c.b. V10-V13 (V20-V23)

Installation position ofthe printed circuit boards .............. 14

Mode of Operation ......................................................... 14

Pause time ................................................................. 15

Lubricating time .......................................................... 15

Time storage .............................................................. 15

Time Setting ................................................................... 16

Factory setting ............................................................ 16

Pause time setting ...................................................... 17

Lubricating time setting .............................................. 17

Operational Test /

To Trigger an Additional Lubrication Cycle ................ 18

Fault indication ........................................................... 18

To remedy a fault ............................................................. 18

Repair .............................................................................. 18

Jumper position combinations - survey ............................ 19

Maintenance, Repair and Tests

Maintenance .................................................................... 20

Pump filling ................................................................. 20

Repair

Pump .......................................................................... 21

Replace pump element .............................................. 21

Control p.c.b. .............................................................. 21

- Electrical connection ...................................................... 22

- Operation with bayonet plug .......................................... 22

Tests

Operational Test /

Triggering an Additional Operating Cycle ................... 23

To check the pressure relief valve .............................. 23

Funcional test of the control p.c.b. ............................. 23

Troubleshooting ............................................................. 24

Technical Data

Rating .............................................................................. 25

Electrical Data .................................................................. 26

Connection Diagrams ...................................................... 27

Declaration by the manufacturer .................................. 30

Lincoln worldwide .......................................................... 31

For further information refer to:

Technical Description Progressive Metering Devices for

Grease and Oil, model SSV, SSVM and SSVD

Technical Description for ”Electronic Control Units” of

pump 203:

- Control p.c.b. 236-13857-1 - Model H

- Control p.c.b. 236-13870-3 - Model M 08-M 15

- Control p.c.b. 236-13870-3 - Model M 16-M 23

External Control Unit 236-13894-1

Installation Instructions

Parts Catalogue

Parts Catalogue Pump 203

Technical Description P203 DC

Technical Description P203 AC

Technical Description P203 with 15 L reservoir

Technical Description P203 with Follower Plate

Lubricants

Keep this user information always at hand

at the place of work of the pump!