Quick Start Guide

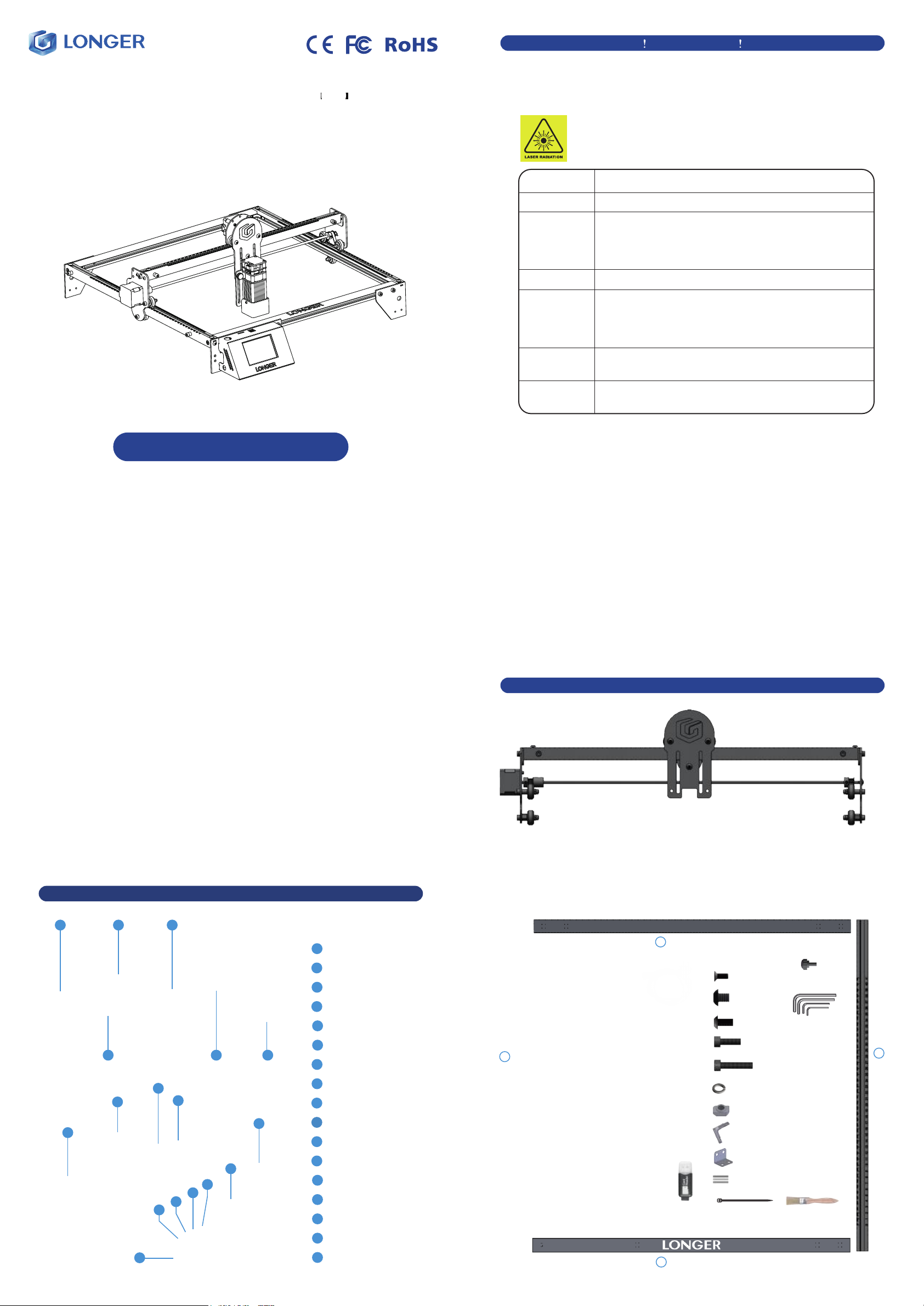

LONGER LASER ENGRAVER RAY5

LASER ENGRAVER INTRODUCTION

www.longer3d.com

ATTENTION

The RAY5 engraves and cuts materials by the means of a high-energy diode laser beam.

The hazards associated with a high-energy diode laser beam include the possibility of fires,

generation of hazardous and/or irritating toxic fumes, but more importantly damage to eyes

and skin.

The high energy laser beam can cause severe eye damage, including blindness and serious

skin burns.

Improper use of the controls and modification of the safety features may cause serious eye

injury and burns.

We strongly recommend placing the machine in a well-ventilated room, and at the same

time, the door of the room has a sealing effect and the windows have curtains, so as to

effectively avoid looking directly at the laser beam and some smoke and steam , Particles

and other highly toxic substances. At the same time, you can pay attention to the Longer

products (cover) in the follow-up.

The high-energy diode laser beam can produce extremely high temperatures and significant

amounts of heat as the substrate material is burned away while engraving and cutting. Some

materials are prone to catch fire during cutting operations creating flame, fumes and smoke.

Although the RAY5 has a built in flame sensor, this technology should NOT be considered

100% accurate and should be seen only as a warning system.

P.S. During the working process of RAY5, if a flame is found, the machine will stop the laser

and make a sound to indicate abnormal conditions. Please pay attention to the working

status of the machine.

During operation to ensure that any flare ups/ flame are properly contained and extinguished.

DO NOT look directly into the laser beam;

DO NOT aim the laser beam at reflective surfaces;

DO NOT operate the laser without PPE protection for all persons nearby in the

proximity of the RAY5;

DO NOT allow unsupervised access to the RAY5 to children;

DO NOT allow access near the RAY5 to pets;

DO NOT modify or disable any safety features of the laser system;

DO NOT touch the high energy laser beam;

1.

2.

3.

4.

5.

6.

*Copyright © Shenzhen Longer 3D Technology Co.,Ltd. All Rights Reserved

Thank you for choosing our products.

Please read this manual carefully before use.

Please reference more details on digital manual in TF card about the operation of

Laser Engraver and installation of LaserGRBL or LightBurn.

Please join our Facebook Group:

LONGER Laser Engraver Official Group

Hotline:+1 855-222-8989

If you have any question, please feel free to contact us as above.

9

10

11

12

13

14

X-Axis Motor

Laser Holdel

Power Switch

TF Card Slot

USB Interface

Control Box

Front Frame

15

Right Frame

16

Power cord jack

17

7

8

9

11

16

15

17

14

13

12

10

4

1 2 3

65

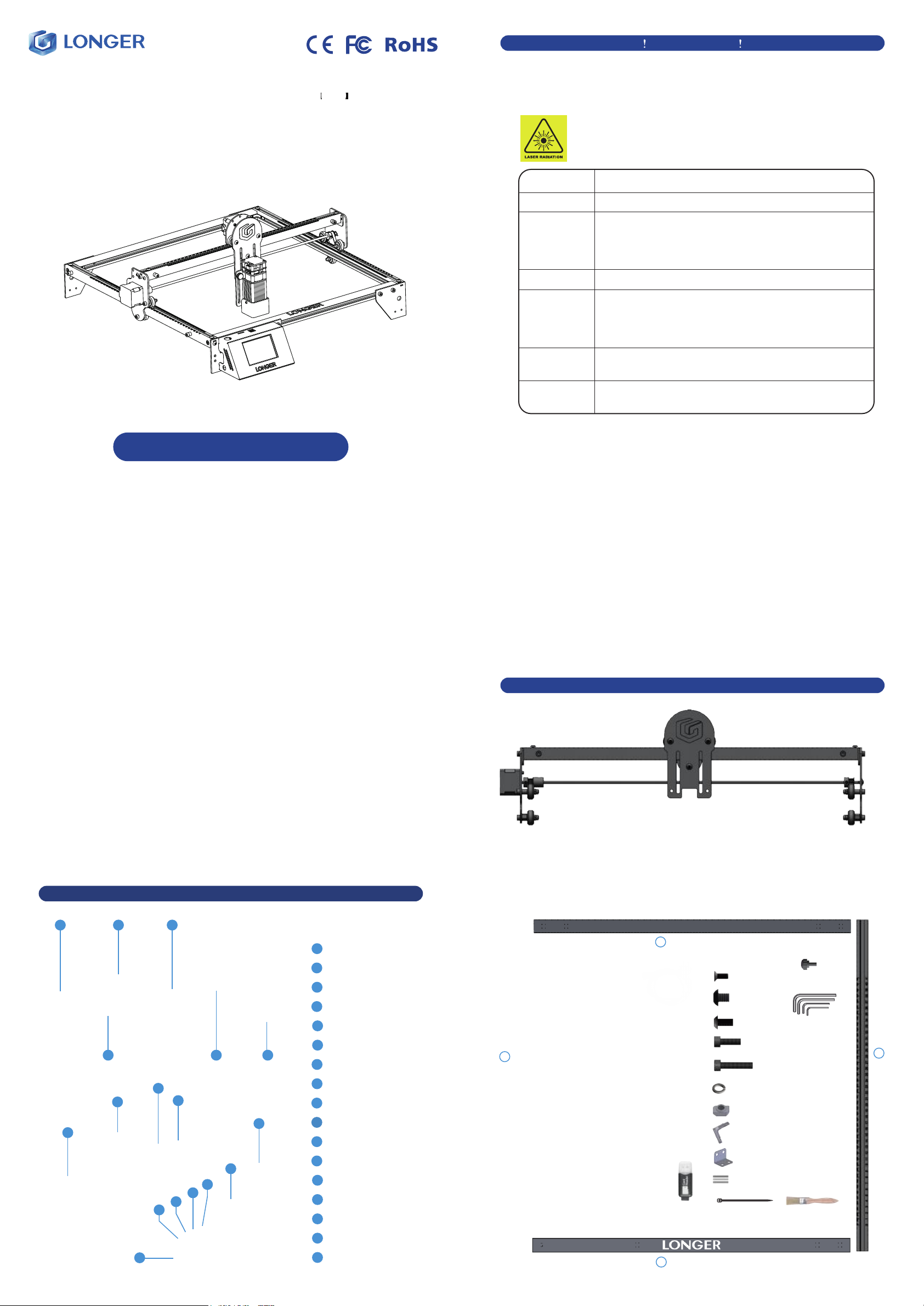

PACKING LIST

Cable Tie

Card Reader

& TF Card

Safety Glasses

Power Cable

USB Cable Wrench

Corner Groove X4

Machine Holder X3

T-shaped Screw X4

Allen Wrench

M5*16X8

M5*25X4

Washer M5X11

M5*6X4

M5*8X1

M3*6X2

Class Definition.

Class I laser radiation is not considered hazardous.

Class IIa laser radiation is not considered hazardous if viewed

for any period of time less than or equal to 1x103 seconds, but is

considered a chronic viewing hazard for any period of time

greater than 1x103 seconds.

Class II laser radiation is considered a chronic viewing hazard.

Class IIIa laser radiation is, depending upon the irradiance,

either an acute in- trabeam viewing hazard or chronic viewing

hazard. If viewed directly with optical instruments, Class IIIa

laser radiation is classified as an acute viewing hazard.

Direct Class IIIb laser radiation is considered an acute hazard to

the skin and eyes.

Class IV laser radiation is considered an acute hazard to the

skin and eyes from both direct and scattered radiation.

Laser class

Class I

Class IIa

Class IIa

Class II

Class IIIb

Class IV

Please wear Personal Protective (Safety Glasses are designed to filter specific

ranges of laser wavelength. The RAY5 Safety Glasses provided are specific

for LONGER Laser Module;) when using the machine Equipment (PPE).

Laser engravers are divided into several internationally valid classes based on

their performance and the risk of injury.The RAY5 falls into the Class IV (Class

4 IEC standard focus on the American FDAclassification).

1

2

3

4

5

6

7

8

X-Axis Beam

Laser Module

Y-Axis Motor

Synchronous Shaft

Touch Screen

Support Feet

Left Frame

Rear Frame

Control Box

Front Frame

Right Frame

X-Axis Frame

Wooden Brush

Timing Belt

Support Feet

Laser Focus Column

Plywood

Left Frame

Rear Frame

Laser Module

Thumb ScrewX2

RAY5 Unboxing Video

1

2

3

4