4

EN

LOOK products are protected by industrial

property rights.

For more information, please refer to

www.lookcycle.com/patents

Your frame has been manufactured according to the technical specications of the LOOK engineering

department.

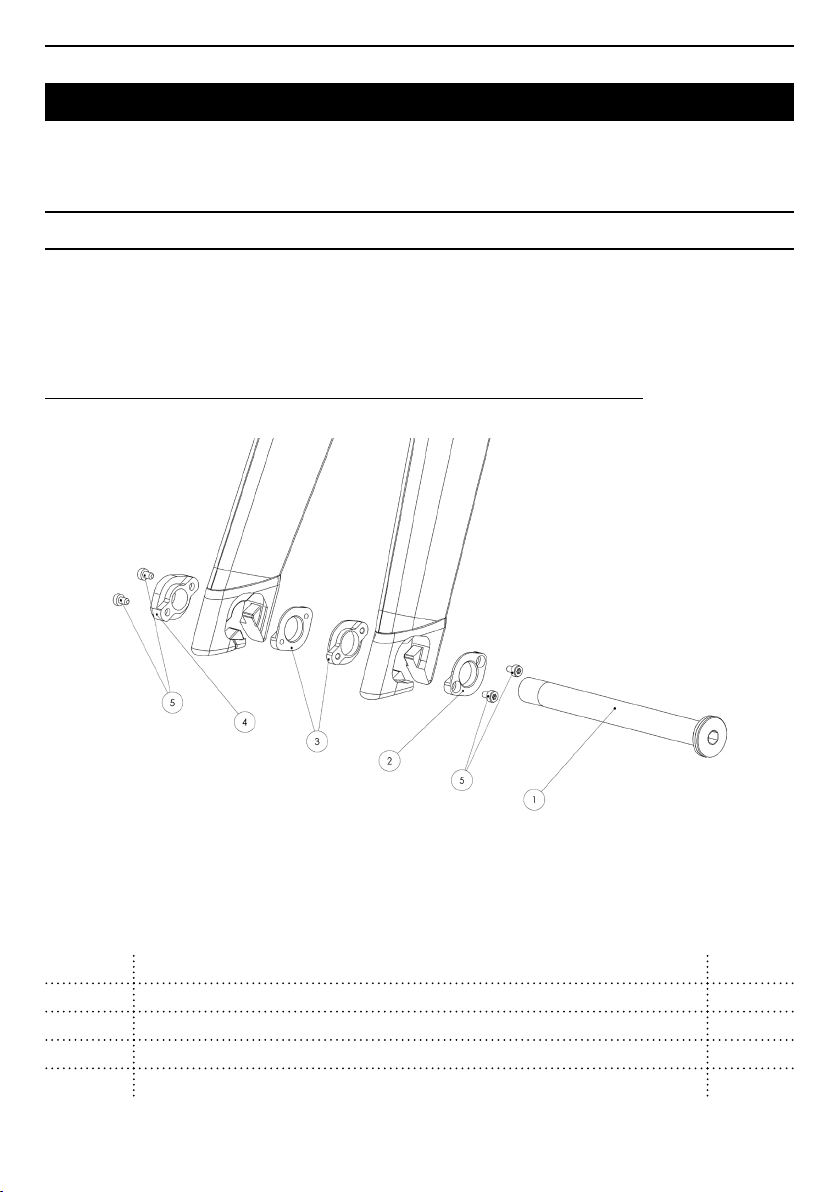

Your frame is delivered with a ZED crankset specially developed for track cycling, an offset fork, a carbon

track stem and aero carbon handlebars.

The frame also comes with a proled seatpost and two carbon saddle clamps.Your T20 bike is compatible

with standard and thru-axle front and rear wheels.

Warning : LOOK products are designed and

optimised for cyclists weighing no more than

100kg (220,5 lbs).

Counterfeit product warning: Using

counterfeit products is extremely dangerous

as these can fail and cause you or third parties to

fall, resulting in serious injury or even death.

PRODUCT INTRODUCTION

IMPORTANT INFORMATION

Before riding, please read these instructions

carefully and respect the recommendations in

order to fully enjoy this beautiful product!

We highly recommend you ask your LOOK

retailer for advice regarding installation and

assembly.

In a constant effort to improve performance,

LOOK reserves the right to modify product

specications without prior notice.

For more information, please refer to our website

www.lookcycle.com, WARRANTY POLICY >

COUNTERFEIT.

For more in-depth details related to IMPORTANT

INFORMATION, please refer to our website

www.lookcycle.com, WARRANTY POLICY >

IMPORTANT INFORMATION.

If you are unable to access our website, your

LOOK retailer can provide you with a print

version of our warranty policies.

!

!