LRX™ RAPTOR

www.lrx-lighting.com

Check on line for the latest updates at www.lrx-lighting.com

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

When the LRX fixture is in FIXTURE mode, pins 4 & 5 on the DMX IN

connector become energized to 12VDC to supply power to the hand controller.

No power is supplied to pins 4 & 5 when in DMX mode. Ensure that fixture is

in the correct mode prior to connecting DMX lines. Always connect the hand

controller to the fixture with the power off. Damage could result if attempting

to connect the hand controller to the LRX fixture while the power is on.

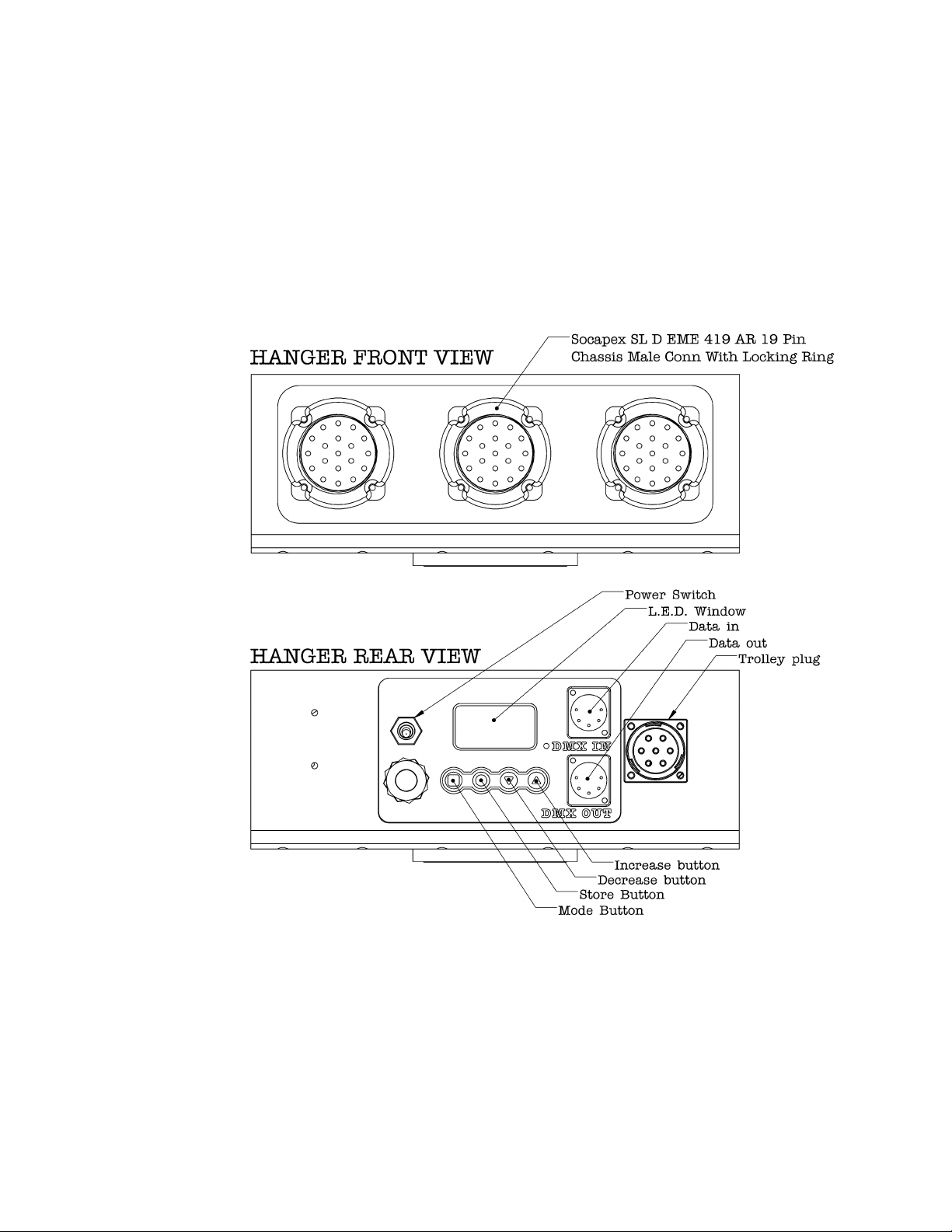

The mode (square icon) on the left is used to toggle between DMX mode and

FIXTURE mode. FIXTURE mode is designated by a capital ‘F’ in the left-most

digit, with the remaining two digits indicating the fixture number. E.g.

F01=fixture#1, etc. DMX mode is shown as a three digit number from 001 to

512. Once the mode is selected the fixture number or DMX address can be

increased or decreased using the up/down arrows on right side of the switch

assembly. When the correct FIXTURE/address has been selected, the store

(round icon) button second from the left is pressed and held (until the display

stops flashing) to store that address.

It is important to note that the LRX

fixture will not begin responding to a newly selected FIXTURE/DMX address

until it has been stored by pressing and holding the store (round icon) button.

If the display is flashing, this is a warning that the displayed FIXTURE/DMX

address does not match the address that fixture is currently responding to.

Saving the displayed address tells the fixture to begin listening and responding

to the new address. If the address is not stored within five seconds it will

return to the previous set

The LRX fixture always writes the last saved address and mode to non-volatile

memory, such that in the event of a power interruption, the fixture will power

up with the mode and address it was using before the power interrupt.

Pressing and holding the mode button will provide access to the hour meter.

Once in hour meter mode press the up icon to display bulb hours, indicated as

a scrolling number. It will show as a blank digit followed by three digits then a

decimal place and two more digits (i.e. _120.59). The bulb hours can be reset

by pressing and holding the store button until the meter zeros, about five

seconds.

To display fixture hours, press the down icon. Fixture hours will be displayed

as a scrolling number with an “F” prefix. This can’t be reset by the user.