LRX™ SCORPION

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

FILE: S- DRIVE – DAVID – LRX-650 – TEXT – Scorpoin-650 se up manual.doc –

Word documen and PDF - LAST REVISED – Augus 10, 2008

4

4

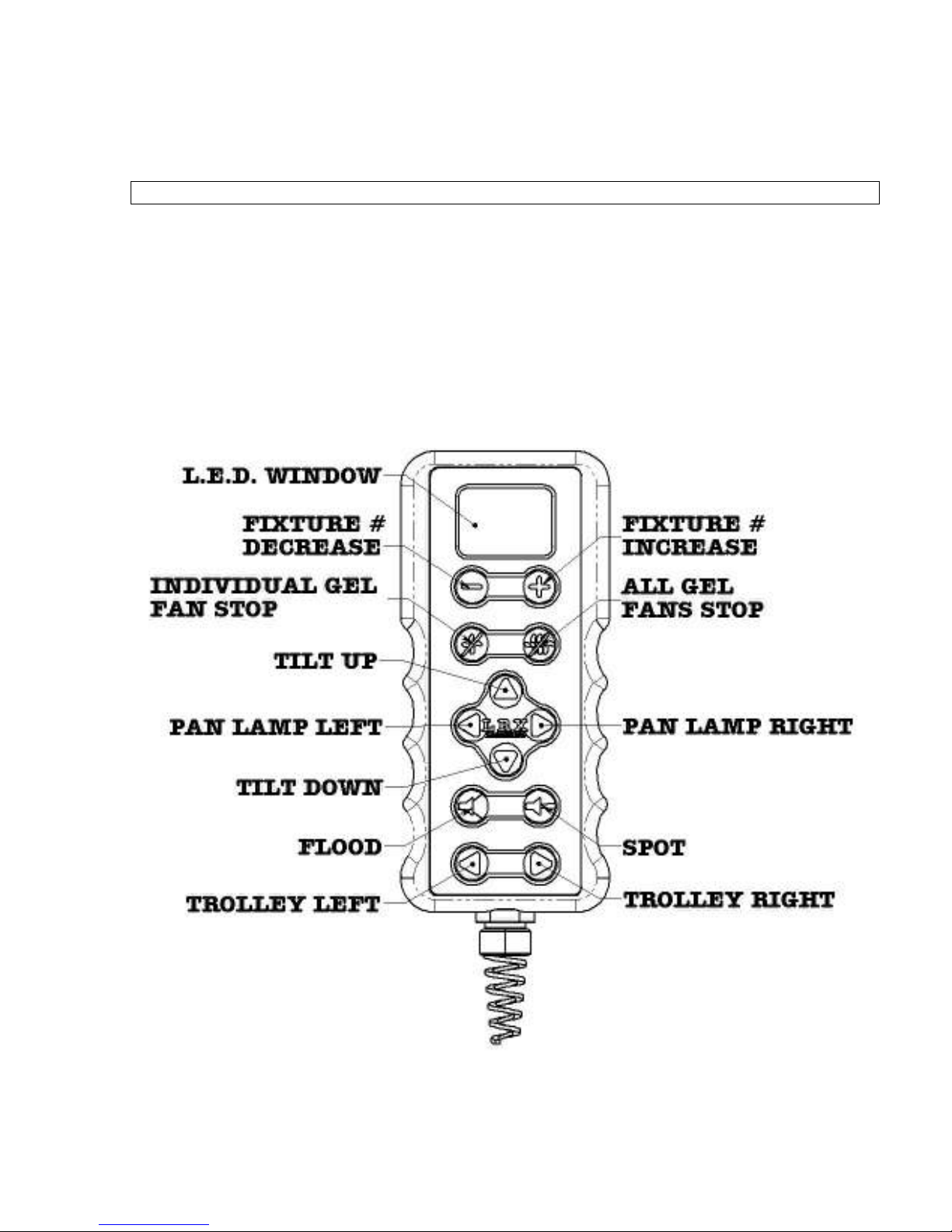

If (MODE = BUMP): (n+13<127)

(N+0 > 127) = pan lef

(N+1 > 127) = pan righ

(N+2 > 127) = il up

(N+3 > 127) = il down

(N+4 > 127) = spo

(N+5 > 127) = flood

(N+6 hru 9) = reserved (fu ure use)

If (MODE=FADER): (n+13>=127)

(N+0 < 64) = pan lef

(N+0 > 127) = pan righ

(N+1 < 64) = il up

(N+1 > 127) = il down

(N+2 < 64) = spo

(N+2 > 127) = flood

(N+3 hru 9) = reserved (fu ure use); Each mo or above is s opped when he

fader is in he middle of i s range (DMX value 64-127).

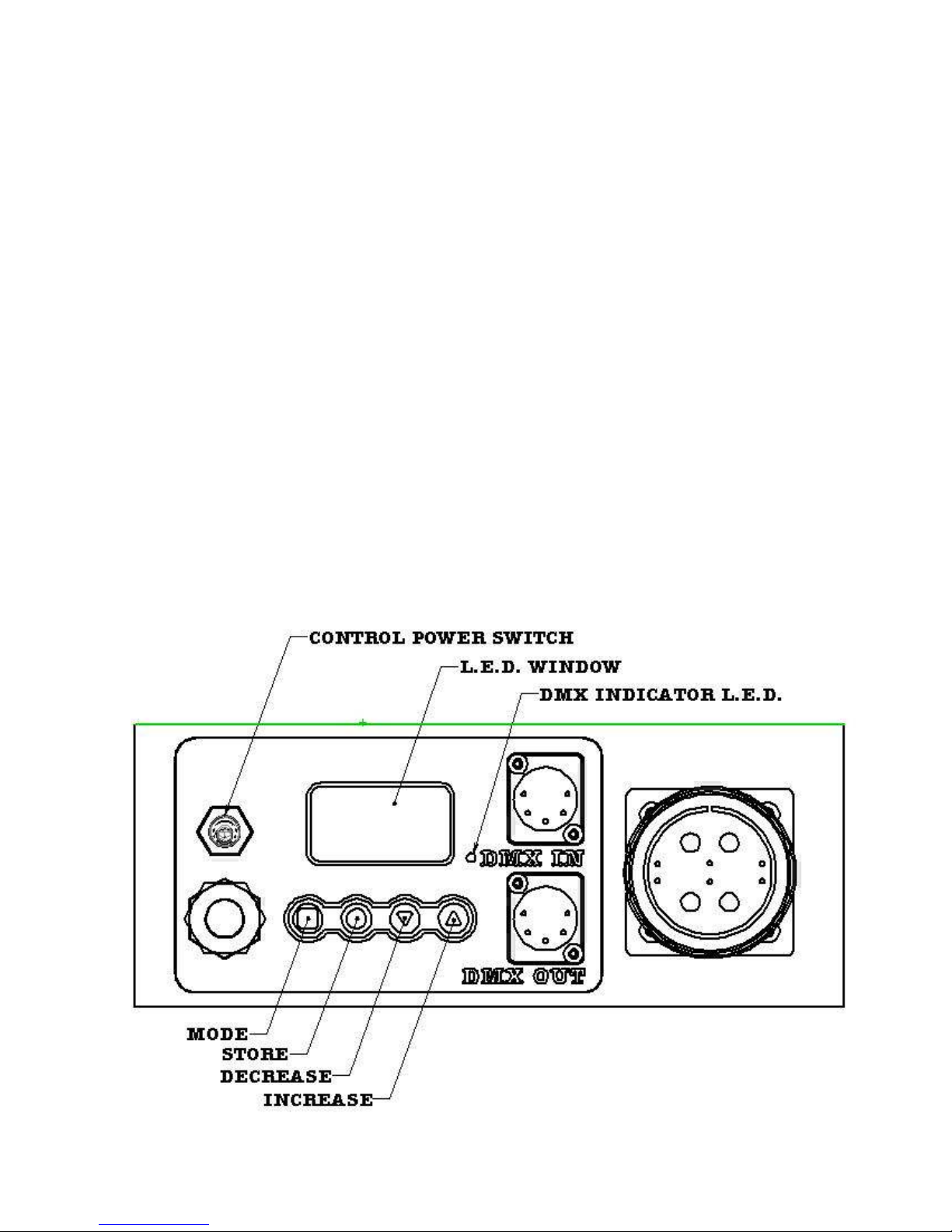

FIXTURE ADDRESSING

Lamp addressing is performed a he rear of he hanger assembly. The fix ure can be

programmed o opera e in DMX mode or FIXTURE mode (for use wi h he hand

con roller). Because each LRX fix ure requires six een DMX channels for opera ion,

FIXTURE mode is merely a convenien way of skipping DMX channels in 16 channel

incremen s, beginning wi h DMX channel #001. Addi ionally, fix ure mode provides

power o a connec ed hand con roller, which is also designed o work in 16 channel

incremen s.

The mode (square icon) on he lef is used o oggle be ween DMX mode and FIXTURE

mode. FIXTURE mode is designa ed by a capi al ‘F’ in he lef -mos digi , wi h he

remaining wo digi s indica ing he fix ure number. E.g. F01=fix ure#1, e c. DMX

mode is shown as a hree digi number from 001 o 512. Once he mode is selec ed he

fix ure number or DMX address can be increased or decreased using he up/down

arrows on righ side of he swi ch assembly. When he correc FIXTURE/address has

been selec ed, he s ore (round icon) bu on second from he lef is pressed and held

(un il he display s ops flashing) o s ore ha address.

I is impor an o no e ha

he LRX fix ure will no begin responding o a newly selec ed FIXTURE/DMX address

un il i has been s ored by pressing and holding he s ore (round icon) bu on.

If he

display is flashing, his is a warning ha he displayed FIXTURE/DMX address does

no ma ch he address ha fix ure is curren ly responding o. Saving he displayed

address ells he fix ure o begin lis ening and responding o he new address.