LSIS H100 Programming manual

Other LSIS Inverter manuals

LSIS

LSIS iG5H Series User manual

LSIS

LSIS SV110IP5A-4NE User manual

LSIS

LSIS sv-ig5a User manual

LSIS

LSIS SV-iV5 Series User manual

LSIS

LSIS LSPV Series User manual

LSIS

LSIS LSLV-S100 Series User manual

LSIS

LSIS H100-2 User manual

LSIS

LSIS iS7 PROFInet User manual

LSIS

LSIS LSLV-S100 Series User manual

LSIS

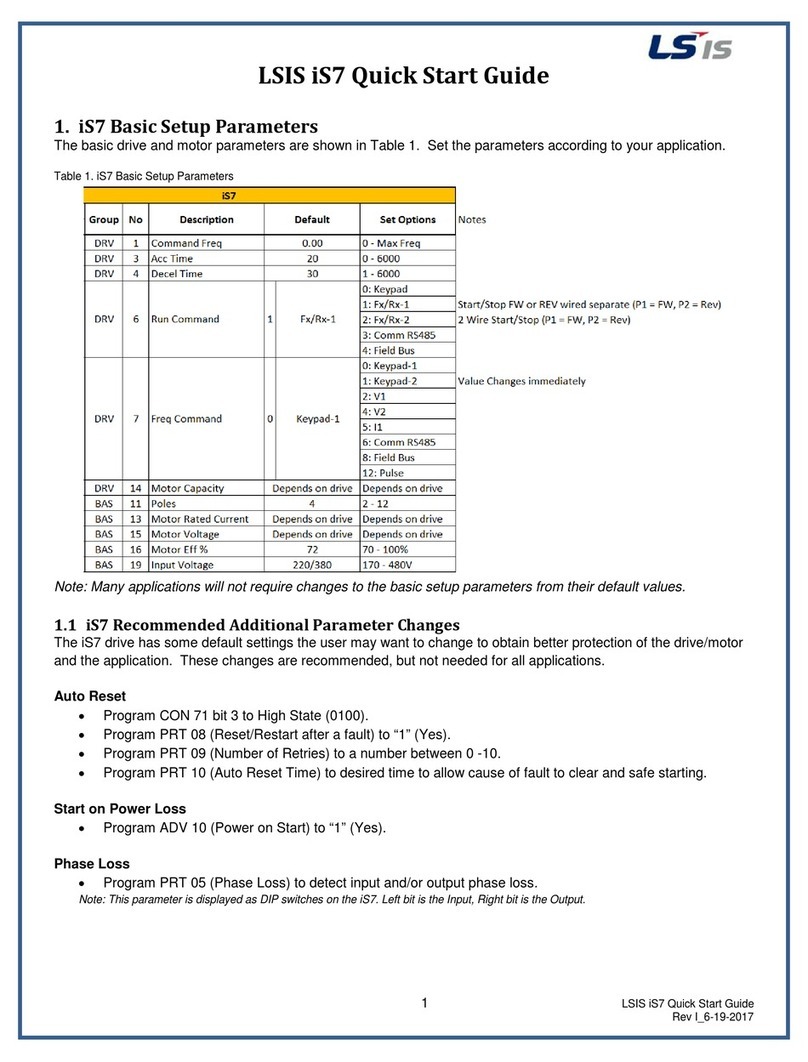

LSIS SV-iS7 series User manual