Contents

AC10 Series Frequency Inverter Technical Manual II

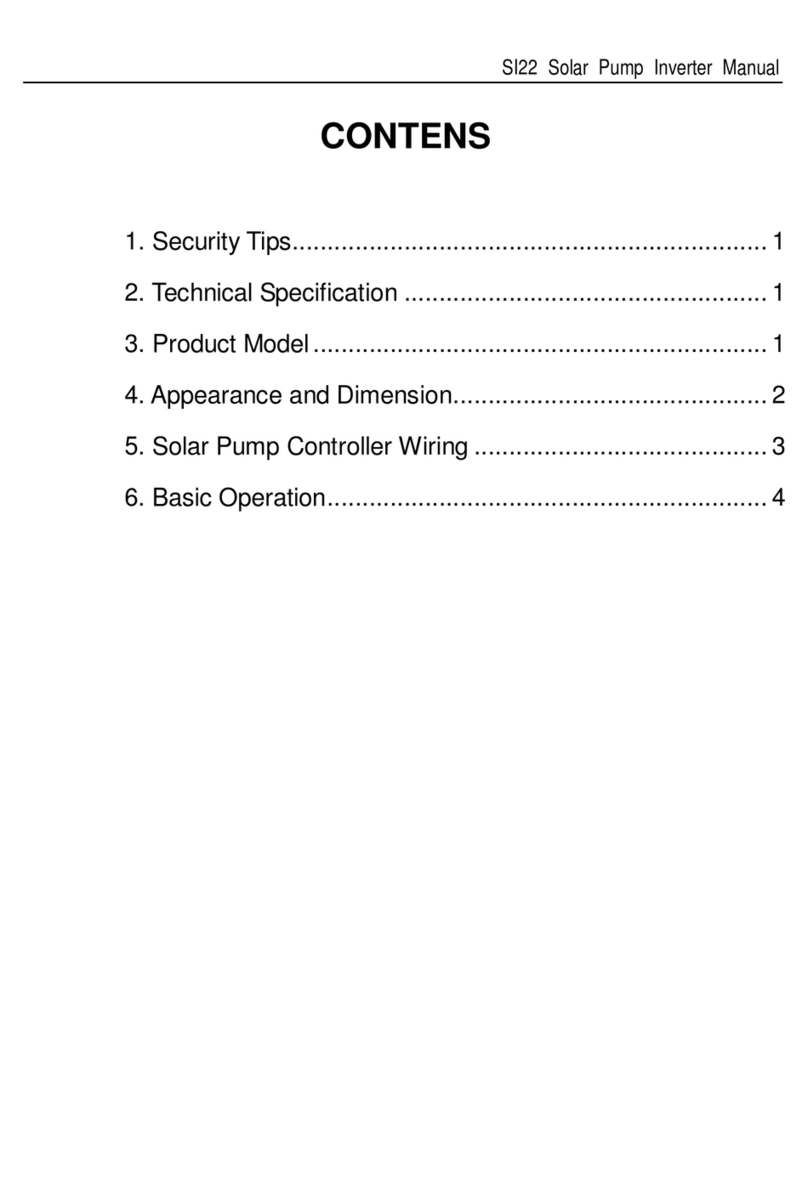

Contents

Quick directory.................................................................................................................................................................................................I

Contents .........................................................................................................................................................................................................II

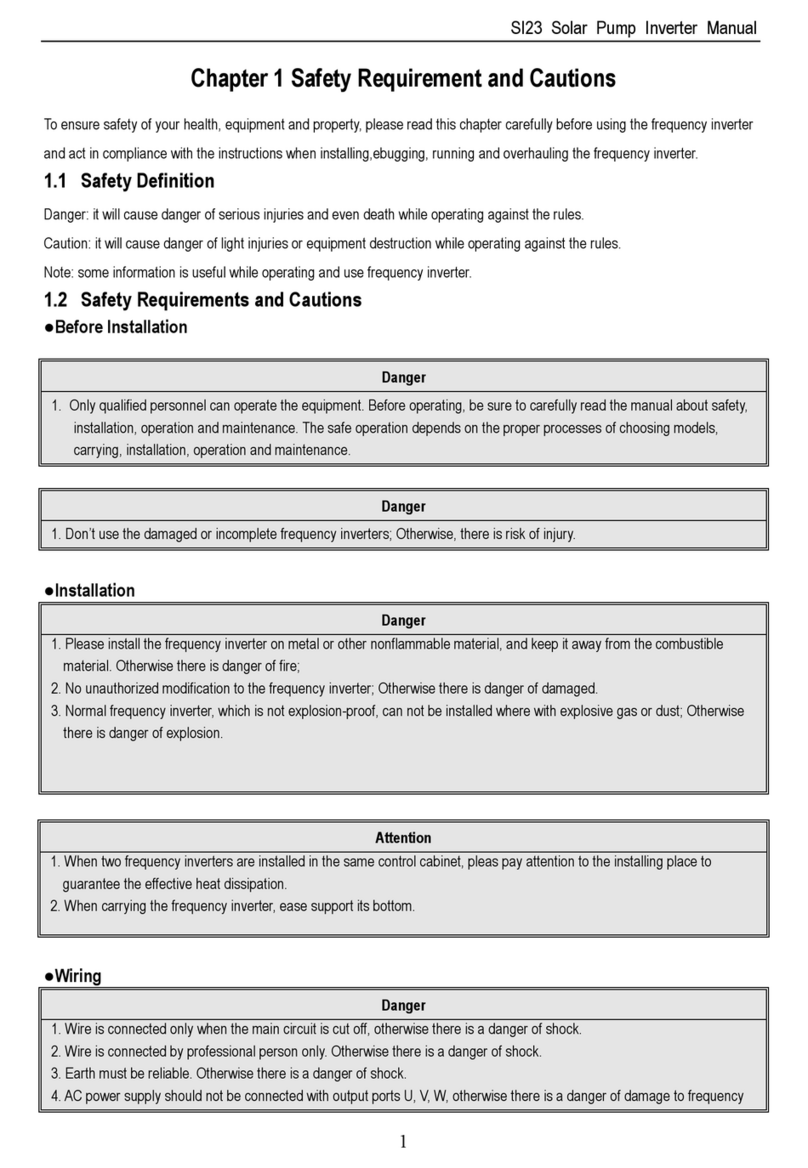

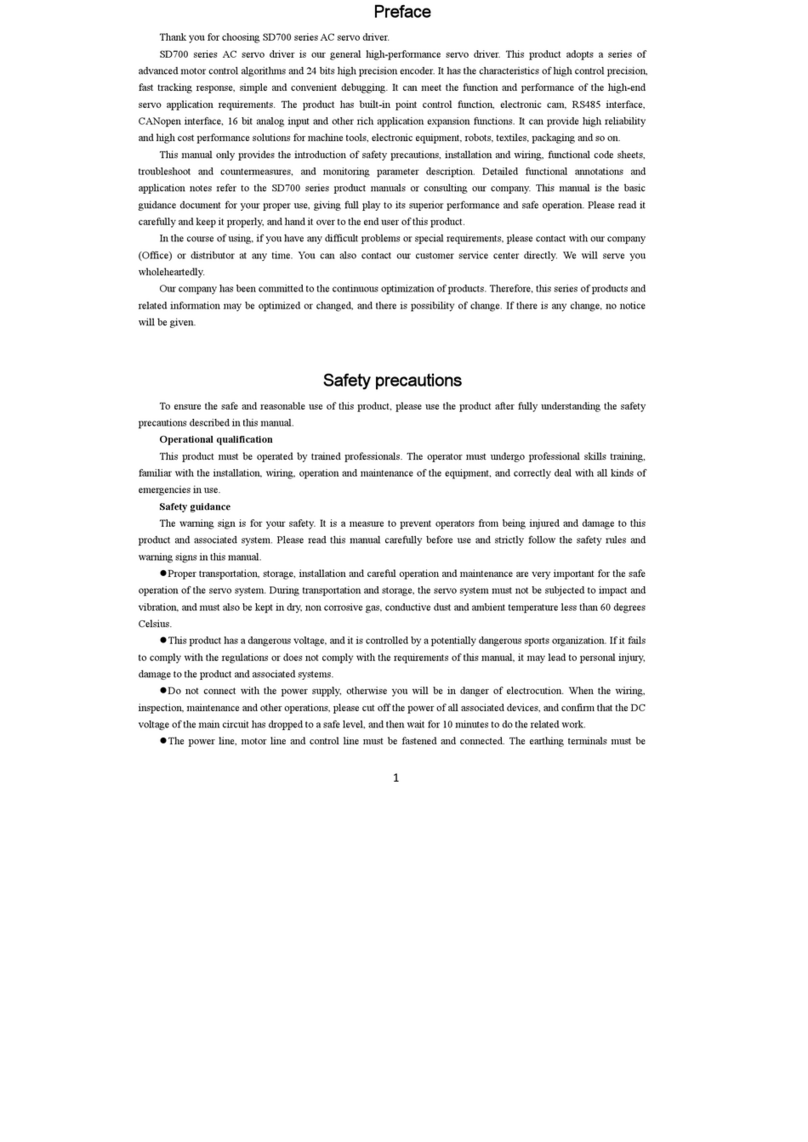

1 Preface and Precautions .......................................................................................................................................................................1

1.1 Before Using ......................................................................................................................................................................................1

1.2 Safety Instructions..............................................................................................................................................................................1

1.3Special Use Instructions......................................................................................................................................................................3

2 Before Use.............................................................................................................................................................................................4

2.1 Safety Notes.......................................................................................................................................................................................4

2.2 Drive model and nameplate ...............................................................................................................................................................4

2.3 Frequency Drive Technical Specifications..........................................................................................................................................5

2.4 Drive rated output current ..................................................................................................................................................................6

2.5 Drive Default Acceleration and Deceleration Time.............................................................................................................................7

2.6 Drive Default Voltage Protection Point ...............................................................................................................................................7

2.7 Types and Characteristics of Control Modes......................................................................................................................................7

3 Installation and Wiring ...........................................................................................................................................................................8

3.1 Safety Precautions .............................................................................................................................................................................8

3.2 Installation Environment.....................................................................................................................................................................8

3.3 Installation Direction and Space.........................................................................................................................................................9

3.4 Dimensions ......................................................................................................................................................................................10

3.5 Standard Wiring ...............................................................................................................................................................................13

3.6 Main Circuit Wiring ...........................................................................................................................................................................17

3.7 Control Circuit Wiring .......................................................................................................................................................................19

3.8 Set the Braking Resistor ..................................................................................................................................................................21

3.9 Standby Control System ..................................................................................................................................................................22

4 Basic Operation and Trial Run.............................................................................................................................................................23

4.1 Safety Precautions ...........................................................................................................................................................................23

4.2 Keyboard Layout and Functions Specification .................................................................................................................................23

4.3 LED Status Indicator ........................................................................................................................................................................25

4.4 Initial Startup Step............................................................................................................................................................................25

4.5 Confirmation at the Time of Initial Startup ........................................................................................................................................28

4.6 Keyboard Operation Method ............................................................................................................................................................29

4.7 Self-tuning ........................................................................................................................................................................................29

4.8 Trial Run...........................................................................................................................................................................................30

4.9 Precision Adjustment during Trial Running (Control Performance Optimization) .............................................................................31

5 Network Communication .....................................................................................................................................................................32

5.1 Safety Precautions ...........................................................................................................................................................................32

5.2 MODBUS Communication ...............................................................................................................................................................32

6 Troubleshooting...................................................................................................................................................................................37

6.1 Safety Precautions ...........................................................................................................................................................................37

6.2 Fault, warning, prompt code type.....................................................................................................................................................38

6.3 Fault, Warning, Prompt Code List ....................................................................................................................................................38

6.4 Fault .................................................................................................................................................................................................40

6.5 Warning ............................................................................................................................................................................................46

6.6 Fault reset method ...........................................................................................................................................................................48

6.7 Troubleshooting without prompting on the keyboard .......................................................................................................................49

7 Overhaul and Maintenance .................................................................................................................................................................50

7.1 Safety Precautions ...........................................................................................................................................................................50

7.2 Overhaul...........................................................................................................................................................................................51

7.3 Maintainence....................................................................................................................................................................................52

7.4 Replace the cooling fan....................................................................................................................................................................52

7.5 Replace the drive .............................................................................................................................................................................52

7.6 Custody essentials ...........................................................................................................................................................................53

8 Scrap ...................................................................................................................................................................................................53

8.1 Safety Precautions ...........................................................................................................................................................................53

8.2 Precautions related to scrapping......................................................................................................................................................54

9 Peripheral Equipments and Options....................................................................................................................................................55

9.1 Safety Precautions ...........................................................................................................................................................................55

9.2 Peripheral Equipments .....................................................................................................................................................................55

9.3 The use of peripheral equipments....................................................................................................................................................56

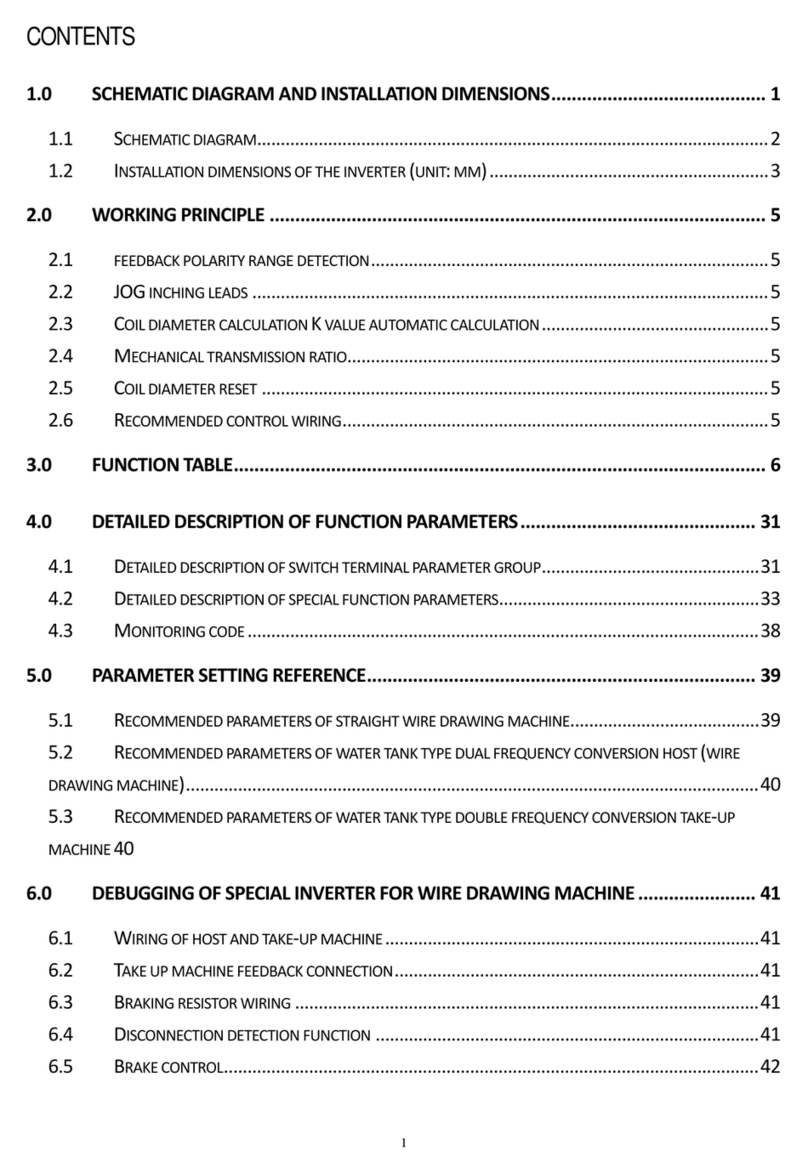

10 Function Table .....................................................................................................................................................................................59

10.1 Safety Precautions .........................................................................................................................................................................59