Table of Contents

CHAPTER 1 - BASIC INFORMATION.............................................................. 1-1

1.1 INSPECTION.........................................................................................................................................1-1

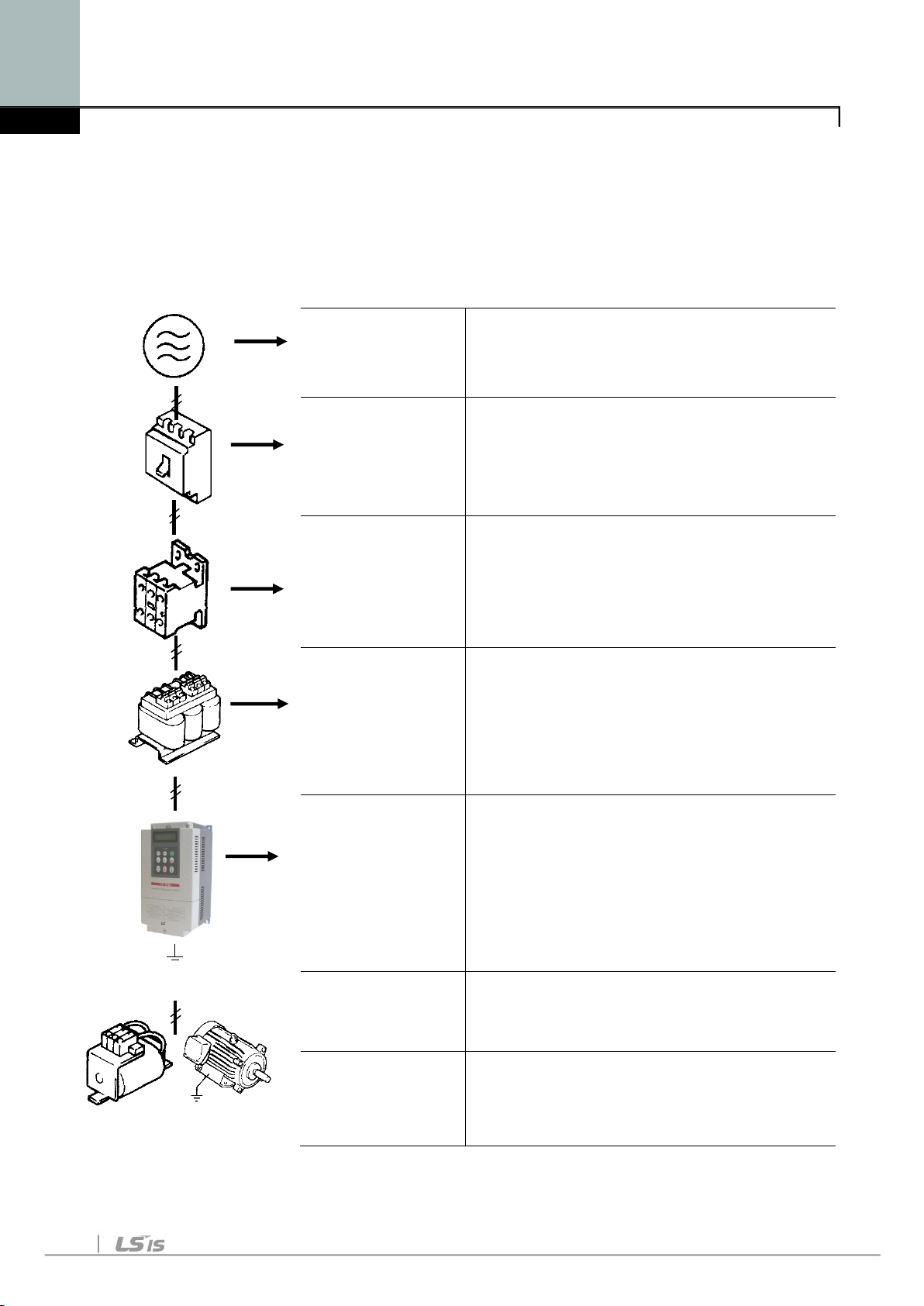

1.2 BASIC CONFIGURATION......................................................................................................................1-2

CHAPTER 2 - SPECIFICATION........................................................................ 2-1

2.1 200~230V CLASS (0.75~30KW/1~40HP)..........................................................................................2-1

2.2 380~480V CLASS (0.75~30KW/1~40HP).........................................................................................2-1

2.3 380 ~480VCLASS (37~90KW/50~125HP)....................................................................................... 2-2

2.4 380 ~480VCLASS (110~450KW/150~700HP).................................................................................2-2

2.5 DIMENSIONS........................................................................................................................................ 2-5

CHAPTER 3 - INSTALLATION ......................................................................... 3-1

3.1 INSTALLATION PRECAUTIONS ........................................................................................................... 3-1

3.2 WIRING ............................................................................................................................................... 3-4

CHAPTER 4 - OPERATION .............................................................................. 4-1

4.1 PROGRAMMING KEYPADS .................................................................................................................4-1

4.2 OPERATING EXAMPLE .......................................................................................................................4-8

4.3 VARIOUS FUNCTION SETTING AND DESCRIPTION ..........................................................................4-13

4.4 OPERATION EXAMPLE ..................................................................................................................... 4-19

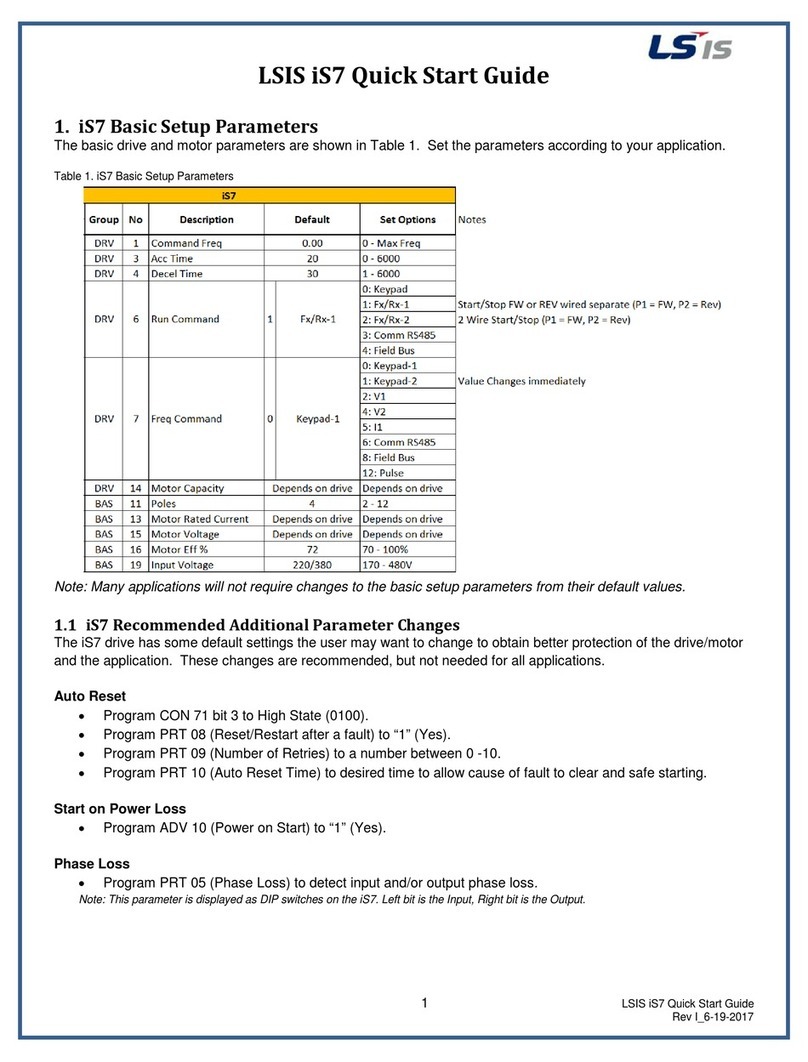

CHAPTER 5 - PARAMETER LIST.................................................................... 5-1

5.1 PARAMETER GROUPS ......................................................................................................................... 5-1

5.2 PARAMETER LIST................................................................................................................................5-2

CHAPTER 6 -TROUBLESHOOTING AND MAINTENANCE........................... 6-1

6.1 FAULT DISPLAY.................................................................................................................................. 6-1

6.2 TROUBLESHOOTING...........................................................................................................................6-7

6.3 HOW TO CHECK POWER COMPONENTS ........................................................................................... 6-8

6.4 MAINTENANCE..................................................................................................................................6-10

CHAPTER 7 - OPTIONS.................................................................................... 7-1

CHAPTER 8 - RS485 COMMUNICATION ........................................................ 8-1

8.1 INTRODUCTION...................................................................................................................................8-1

8.2 SPECIFICATION................................................................................................................................... 8-2

8.3 OPERATION......................................................................................................................................... 8-3

8.4 COMMUNICATION PROTOCOL (RS485)............................................................................................. 8-4

8.5 PARAMETER CODE LIST ..................................................................................................................... 8-8

8.6 TROUBLESHOOTING.........................................................................................................................8-13

8.7 ASCII CODE LIST............................................................................................................................. 8-15

CHAPTER 9 - APPLYING DRIVES TO SINGLE-PHASE INPUT

APPLICATION 9-1

9.1 INTRODUCTION...............................................................................................................................9-1

9.2 POWER(HP), INPUT CURRENT AND OUTPUT CURRENT ................................................................9-2

9.3 INPUT FREQUENCY AND VOLTAGE TOLERANCE ...........................................................................9-2

9.4 WIRING AND PERIPHERAL DEVICE.................................................................................................9-2