P a g e | 1

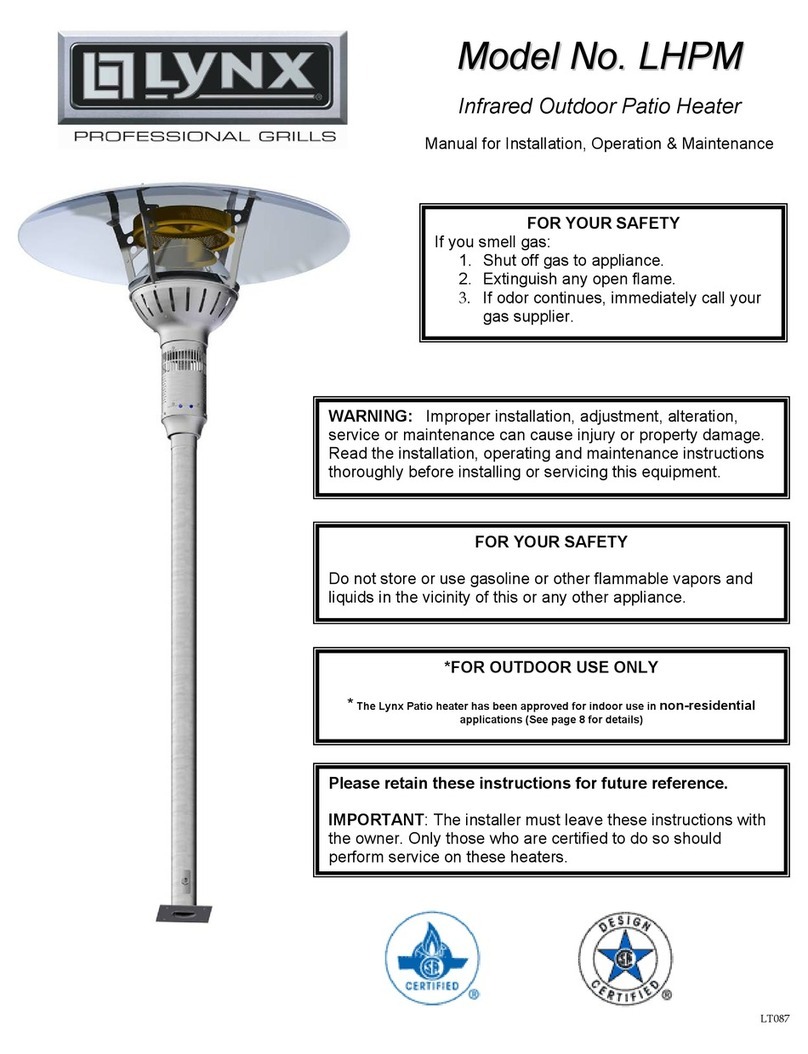

Thank you for your purchase of our LYNX Deluxe Eave Mount Patio Heater. This product has been manufactured with

the highest quality materials available, and combines the most advanced, state of the art, internal components with

cutting edge, heater design technology . This product is sure to provide you many, many, years of enjoyment and

comfort. The design elements of this heater, including its Lynx, signature polished highlights, and slim, attractive

appearance, allow it to be mounted, with pride, in highly visible locations of your home. It will most likely architecturally

blend and enhance any portion of your home in which you chose to install it. Please read this entire manual before

attempting to install or operate your new heater.

Features of your Lynx Eave Mount Patio Heater:

Manufactured completely from Stainless Steel with welded construction

Spark ignition with heat sensing safety pilot

Slim, custom profile

Attractive, adjustable, heavy duty mounting brackets (extension is made from 6 GA, 3/16” thick stainless).

Can be adjusted from 10” to 18”

Mounting pivot adjustability from 0 -30 degrees from the horizontal. Allows for a precise direction of heat.

Decorative safety grill provides wind resistance and protection from sudden gusts.

Convenient, DC operation. Requires no 110V electrical routing for basic installation.

Operates with an attractive, wireless, wall mounted, on-off-hi-low switch.

Operates additionally with a highly sophisticated, touch screen, remote control device.

Remote control provides 6 levels of heat adjustment for NG gas type, and 3 levels for LP gas type.

Heat adjustment is viewable as either a digital temperature readout, or as a numerical readout displaying the

6 heat levels.

Infrared technology provides a burner that generates up to 35,000 BTU’s of heat. Adjustable down to 27,000

BTU’s (LP) and 24,000 BTU’s (NG)

110 V AC Adaptor included.

Optional 12 ft flexible gas line hook-up (works with NG or LP)

Optional, wireless, wall mounted timer allows for a timed, worry-free operation.

Special considerations should be made when selecting a location for your heater before installation. The most important

of which should be a location that will serve to be the most functional and useful in providing heat. Suggested locations

would be under an eave, on a wall of an open or partially enclosed patio, or on a fascia. This heater has been

thoroughly tested and certified to function during and after mild rain storms, and during mild wind conditions. We

would like to point out, however, that by avoiding locations that subject your heater to constant wind or rain exposure,

will greatly extend the life or your new heater. Other considerations should be its mounting position in relation to

combustible materials. Combustible materials include wood, wood fascias, wood siding, stucco mounted over wood

studs, vinyl siding, and drywall. See installation diagrams that reference mounting distances.

MOUNTING CONSIDERATIONS

Select a location that provides the most functionality.

Avoid locations that are prone to direct wind or rain exposure.

This heater provides ample heat and large heat adjustability. It does not have to be located at eye level, as, its

high output will allow a distant location to still be affective.

Do not mount this heater indoors or in a totally enclosed room. It needs air to breath and vent.