JB2

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-2642 Rev.3 P. 3 / 5

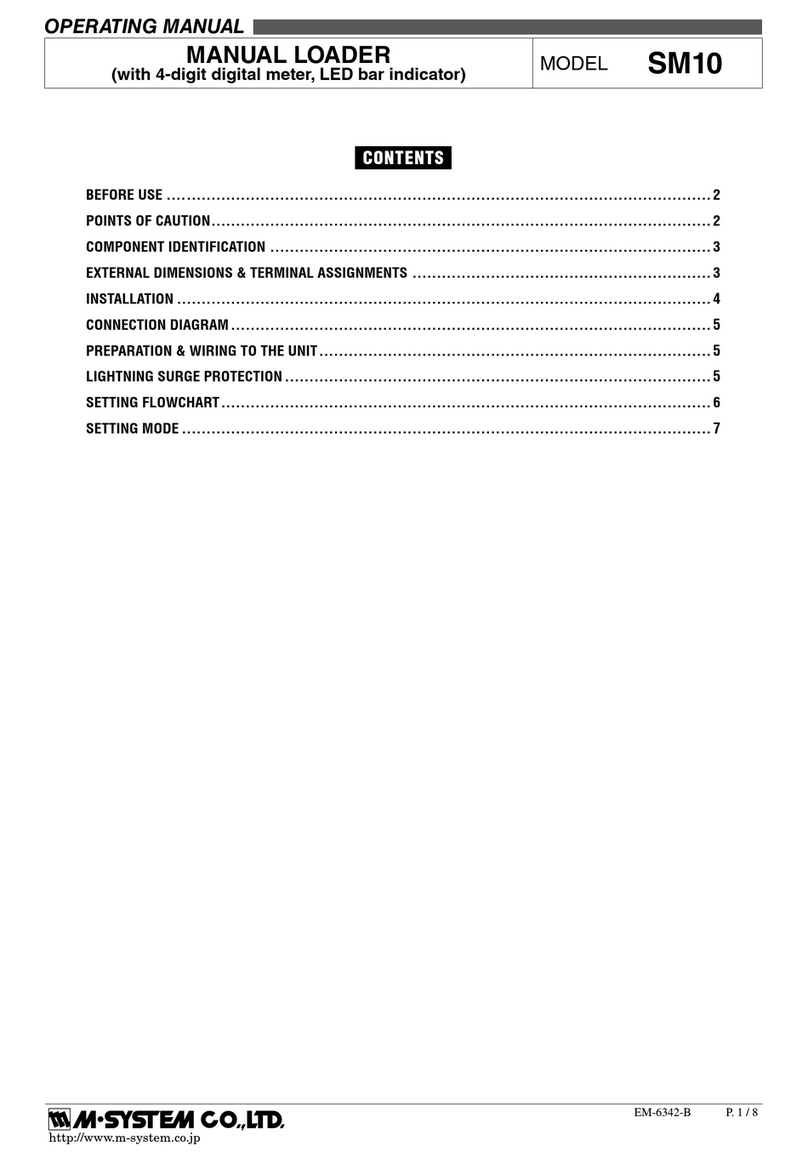

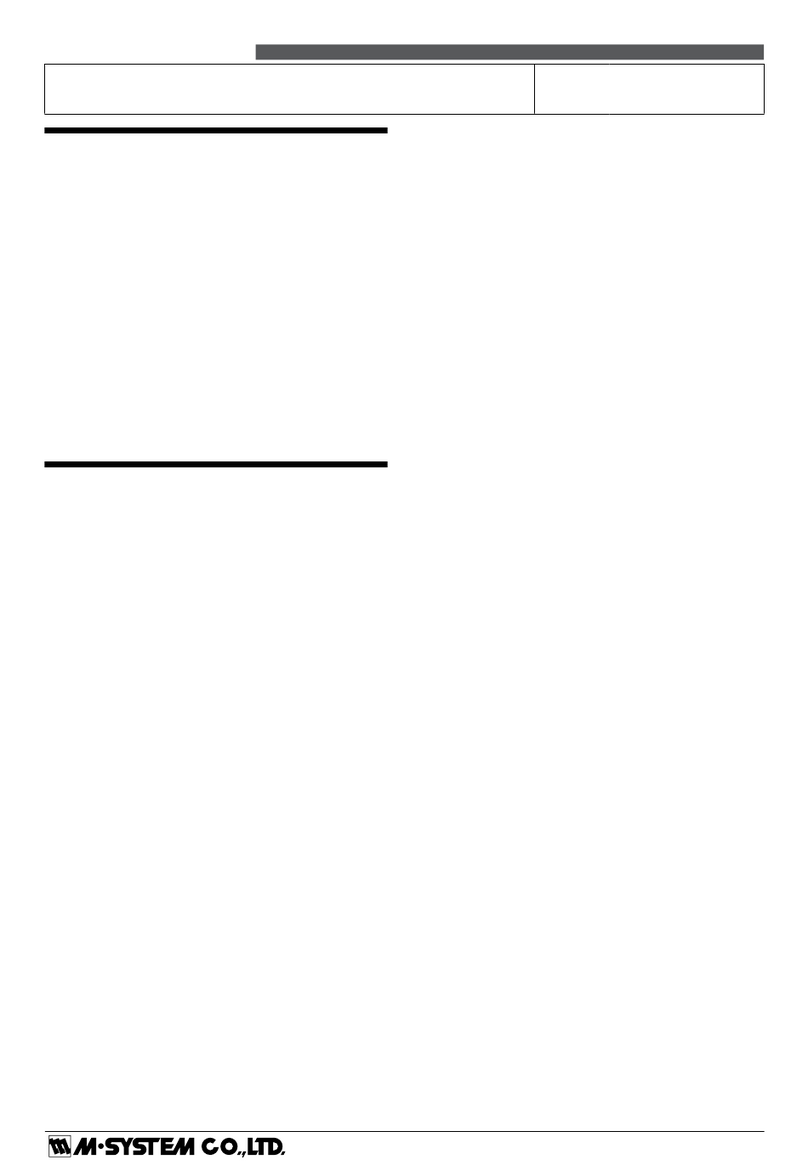

FRONT VIEW & PROGRAMMING

Please refer to the Operation Manual for Model PU-2x (EM-9255), Section A: (A-1) Introduction, (A-2) General Operation

Description, (A-3) General Operation Flow Chart for general information.

Front Cover (open)

Span Adj.

Zero Adj.

RUN Output LED

MAN. Status LED

UP Command LED

DOWN Command LED

MAN. Command LED

Modular Jack

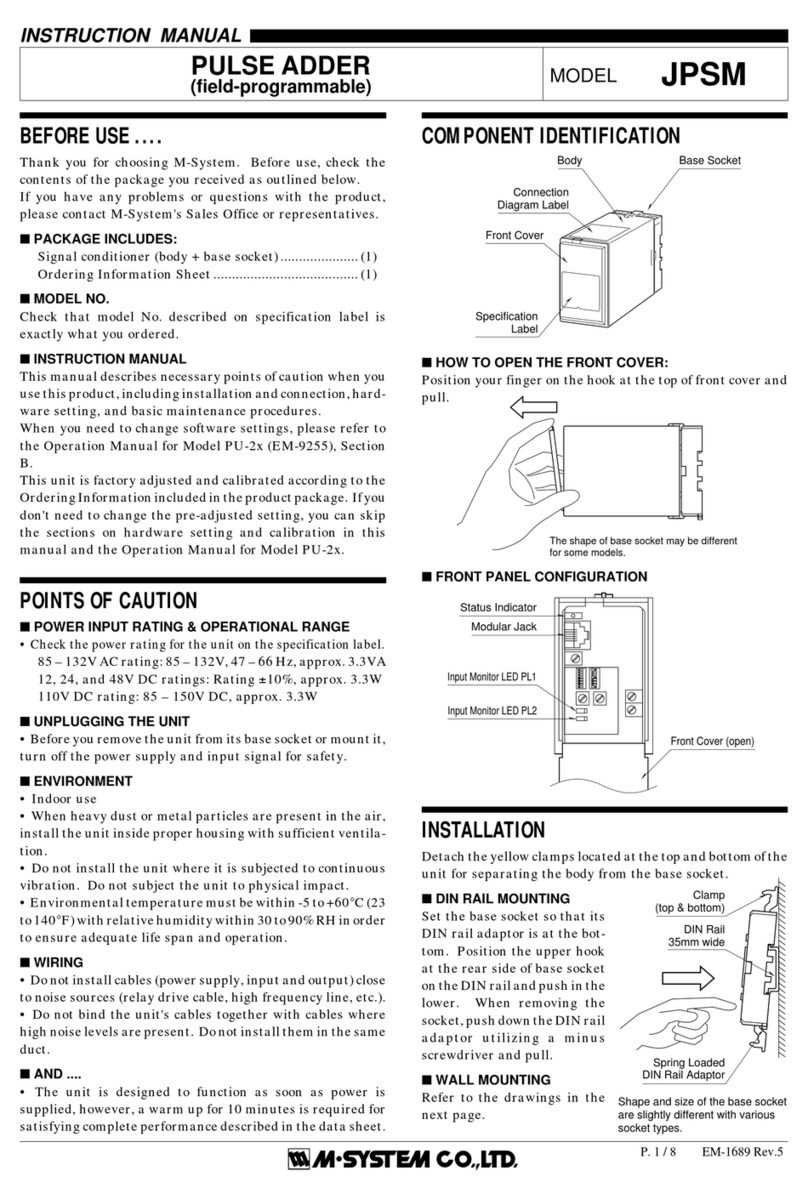

• PROGRAMMING WITH PU-2x

G

ITEM No.

I()

D

Response MessagesGROUP No.

Data to be entered

or Messages

LCD Display

• Response Messages

OK: OK

NG: No good. Check modular jack connection.

ER: Communication error

[GROUP 01]

ITEM MDFY. DATA INPUT DISPLAY CONTENTS

01 S MAINTENANCE SWITCH

0 MTSW : MON.MODE 0: Data indication only.

1 MTSW : PRG.MODE 1: All ‘P’ marked parameters are modifiable. *1

02 P Alphabets & No. TG : XXXXXXXXXX Tag name entry (10 characters max.)

03 D No input OUTPER : XXX.XX Output in %

04 D No input OUTVAL : XX.XXX Output value in mA

05 D No input INPPER : XXX.XX Input in %

06 D No input INPVAL : XX.XXX Input value in mA

10 P WRITE DEFAULT Initializing all setting values to the factory standard ones.

ENTR COMPLETED Initialization complete

21 P Manual control mode (factory set value: 1)

Specifies the initial MV output value when starting MAN control

1 1 : DIRECT CAS control signal value

2 2 : TRACE BACK CAS control signal value going back for ITEM 28 set time period

3 3 : FIXED VALUE Fixed value set in ITEM 29

22 P Numeric SLDBAK : XXX.XX MAN/CAS transition response (%/second)

Selectable range: 0.00 to 200.00

No sliding-back function with 0.00

23 P UP/DOWN response mode (factory set value: 0)

0 0 : UNIFORM Constant ramp rate while the key is held down.

1 1 : ONE+UNIFORM Normal response rate for once when the key is pressed.

Constant ramp rate if it is continuously held down.

22 : ACCELERATED Accelerated response when the key is pressed until it reaches the

constant ramp rate.

24 P Numeric KEYRES : XXX.XX UP/DOWN response time (ramp rate) (%/second)

Selectable range: 0.00 to 200.00 (factory set value: 10.00)

25 P High/Low alarm mode at CAS control (factory set value: 0)

0 0 : NO ALARM No alarm trip

1 1 : LOW ALARM Low alarm trip only

2 2 : HIG ALARM High alarm trip only

33 : ALL ALARM High/Low alarm trip

26 P Numeric ALMLOW : XXX.XX CAS input Low alarm setpoint (%)

Selectable range: -25.00 to 125.00 (factory set value: -25.00)

27 P Numeric ALMHIG : XXX.XX CAS input High alarm setpoint (%)

Selectable range: -25.00 to 125.00 (factory set value: 125.00)

28 P Numeric TRACEBACK : XX.X Retroactive time period (seconds)

Selectable range: 0.0 to 10.0 (factory set value: 0.0)

29 P Numeric MANFIX : XXX.XX Initial manual control value (%)

Selectable range: -25.00 to 125.00 (factory set value: 0.00)

30 P Numeric PWRFIX : XXX.XX Output in % after power on in manual control mode

Selectable range: -25.00 to 125.00 (factory set value: -25.00)

31 P Output value after power on

(see “JB2 Actions when the Power Supply is Recovered after Failure.”)

00: HOLD VALUE The value stored at the moment of power failure

11: FIXED VALUE The value preset in the ITEM 30

32 D No input NVRWRCNT: XXX Number of rewriting E2PROM (32-bit)

Count when changing program or power off