DC/2-PHASE PULSE CONVERTER

(eld-programmable) MODEL JARP2

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■PACKAGE INCLUDES:

Signal conditioner

(body + base socket + input resistor)..................................(1)

Input resistor is provided only with current input type.

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when you

use this product, including installation, connection, hard-

ware setting, operation of the Programming Unit (model:

PU-2x)* specific to this model and basic maintenance pro-

cedures.

This unit is factory adjusted and calibrated according to the

Ordering Information included in the product package. If

you don’t need to change the pre-adjusted setting, you can

skip the sections on hardware setting and calibration and

Software Setting in this manual.

*When you need to change software settings, please refer to

the Operation Manual for Model PU-2x (EM-9255), Section B:

(B-1) Introduction, (B-2) General Operation Description, (B-3)

Operation Flow chart for general information.

POINTS OF CAUTION

■POWER INPUT RATING & OPERATIONAL RANGE

• Locate the power input rating marked on the product and

confirm its operational range as indicated below:

100 – 240V AC rating: 85 – 264V, 47 – 66 Hz,

approx. 4.1VA at 100V AC

approx. 5.9VA at 200V AC

approx. 7.7VA at 264V AC

12 and 24V DC ratings: Rating ±10%, approx. 2.8W

110V DC rating: 85 – 150V DC, approx. 2.8W

■GENERAL PRECAUTIONS

• Before you remove the unit from its base socket or mount

it, turn off the power supply and input signal for safety.

■ENVIRONMENT

• Indoor use.

• When heavy dust or metal particles are present in the

air, install the unit inside proper housing with sufficient

ventilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■WIRING

• Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

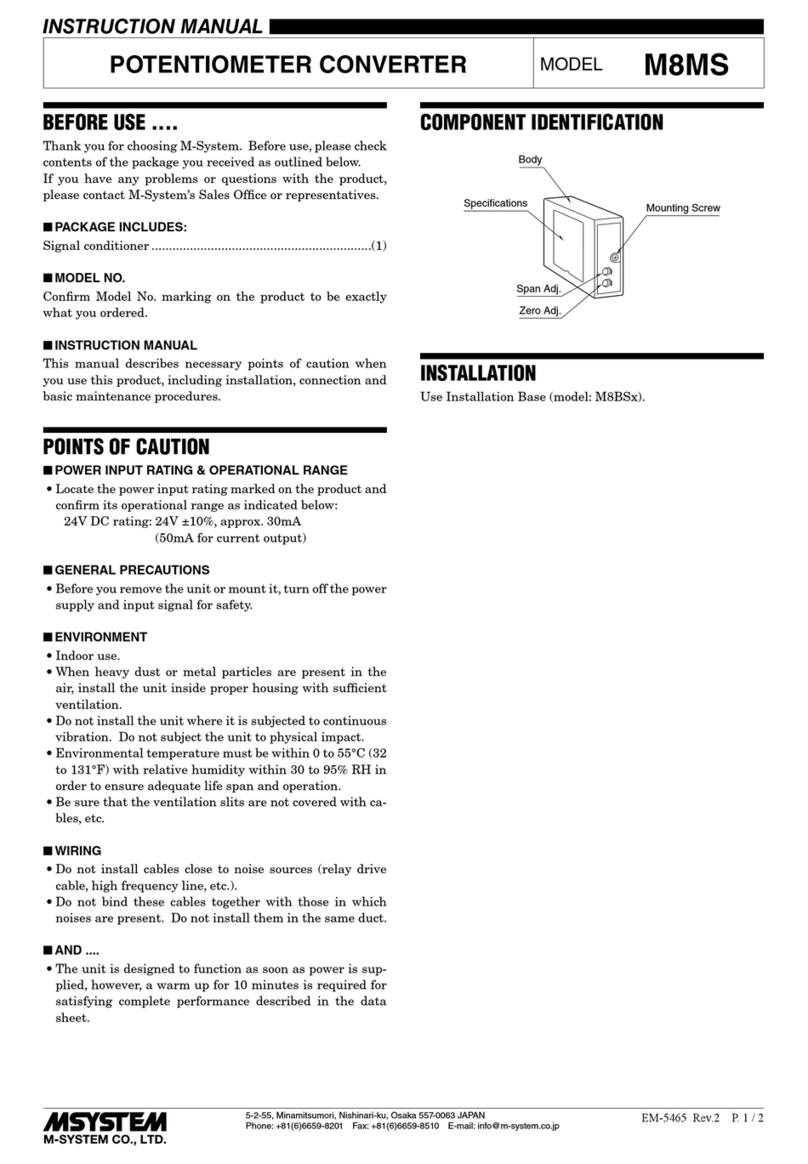

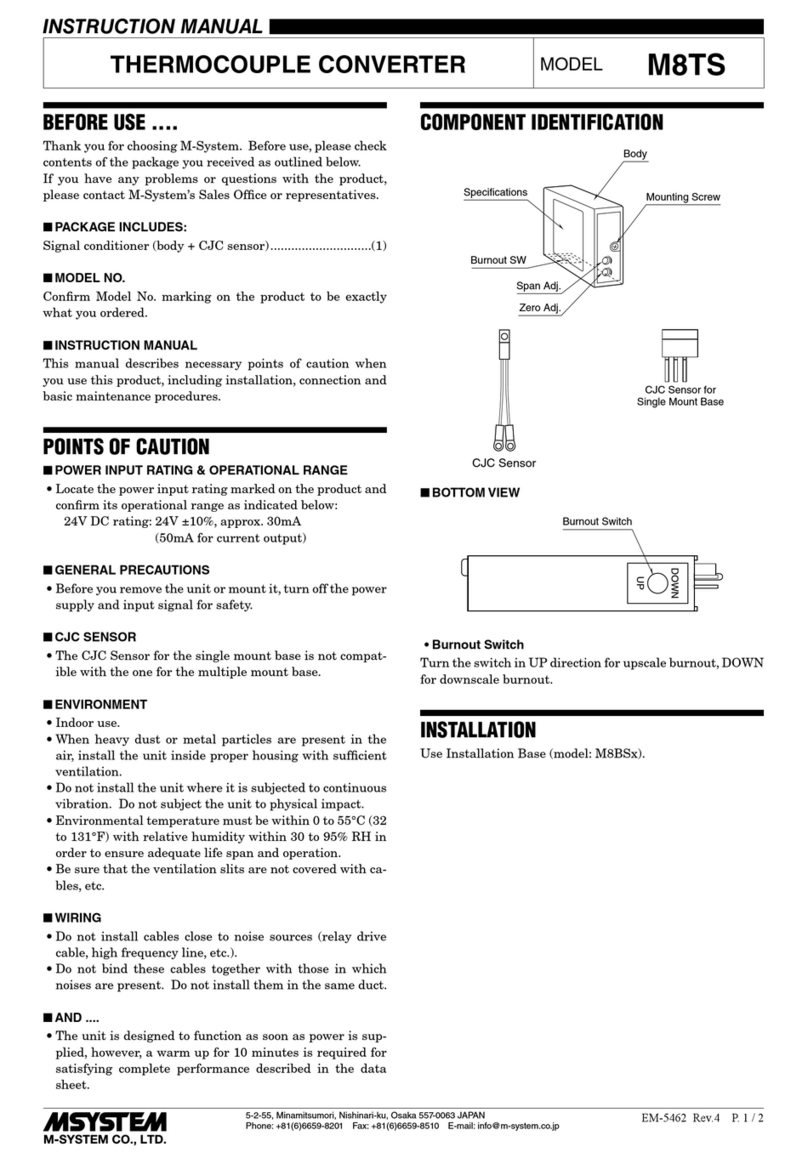

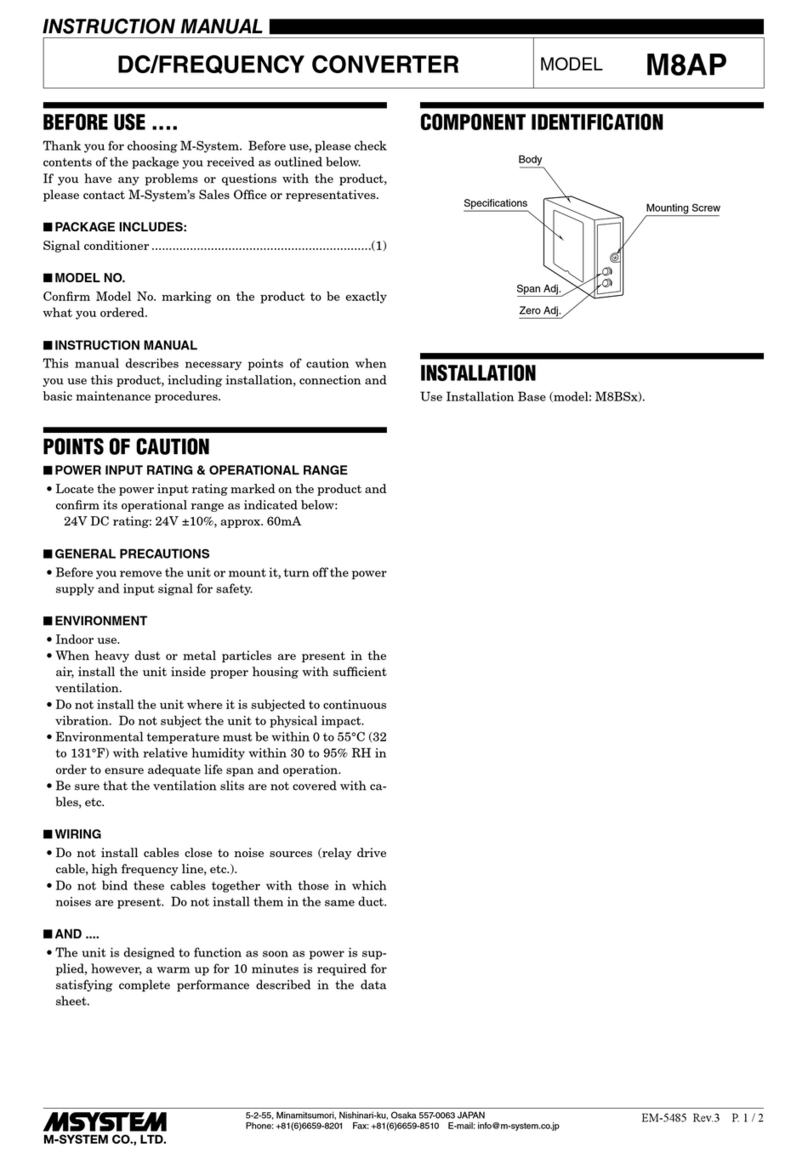

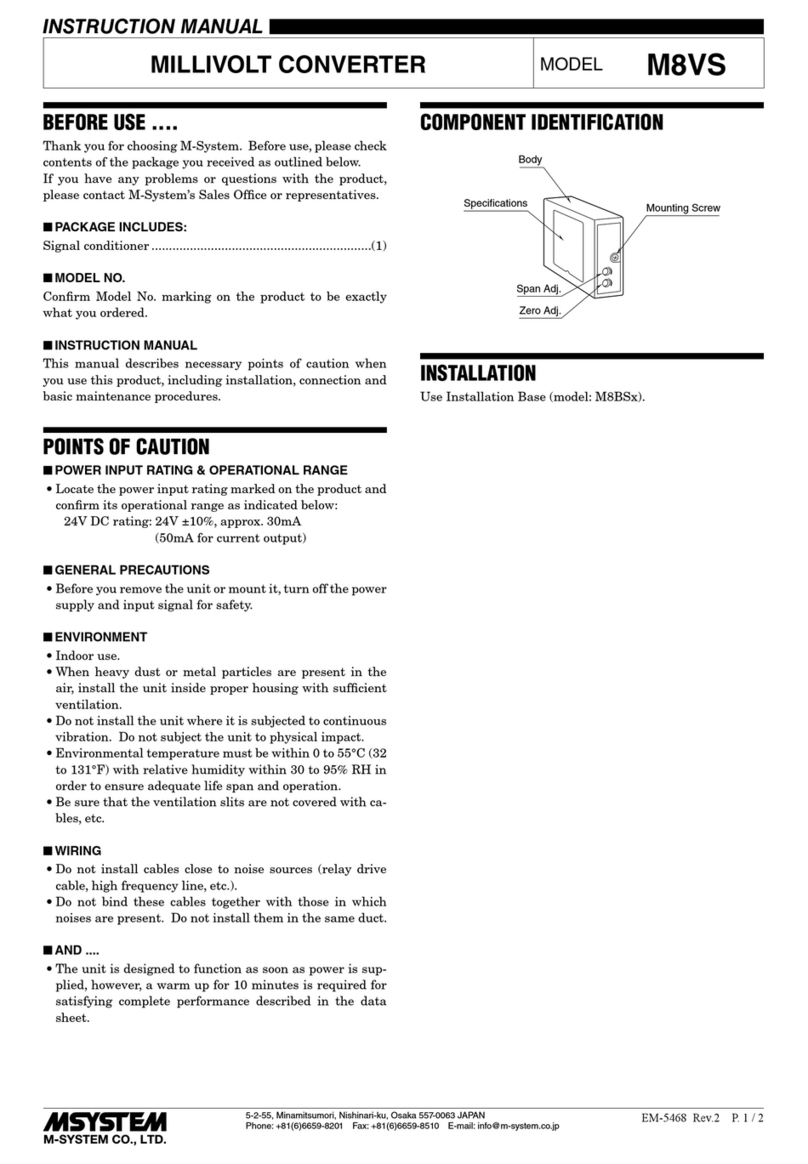

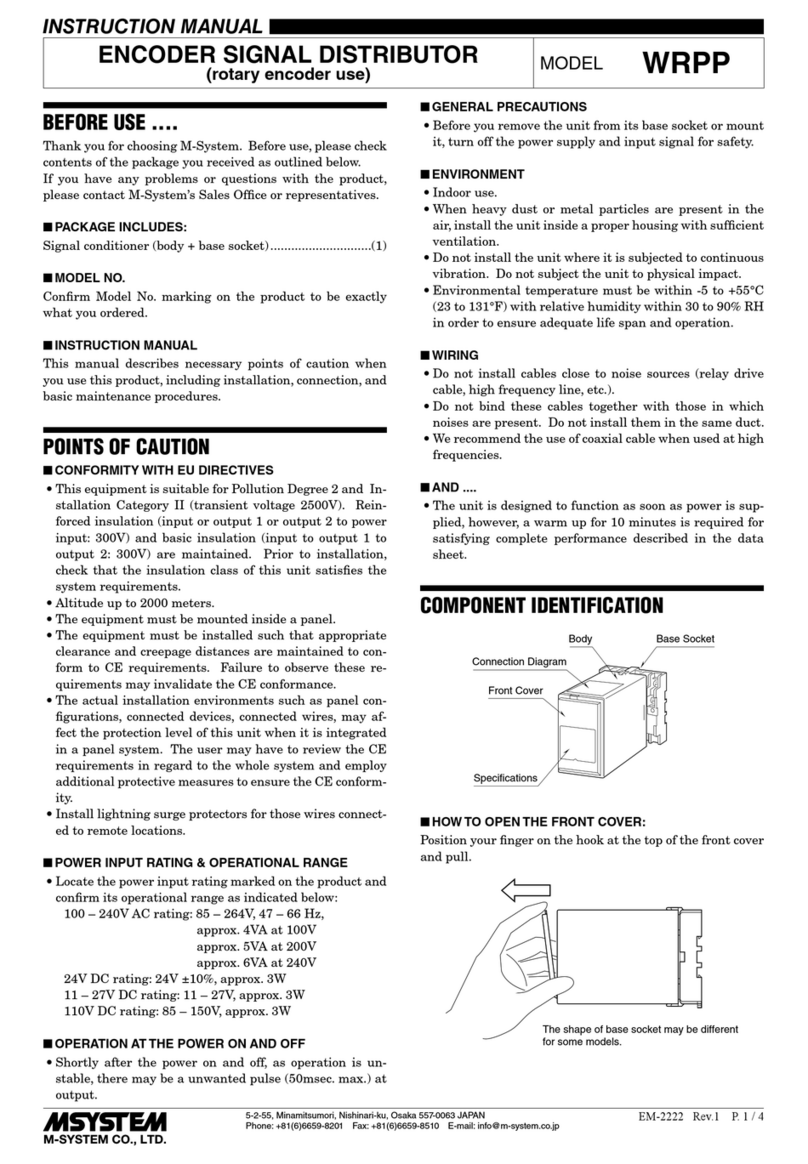

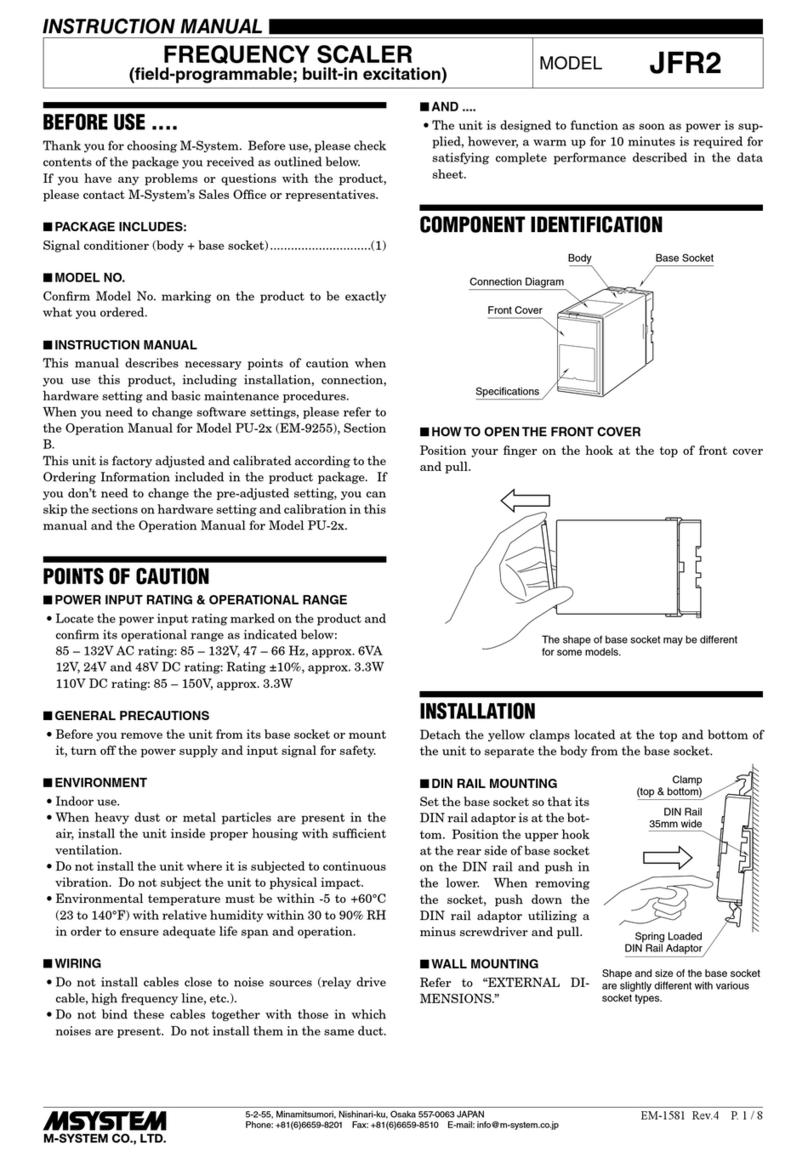

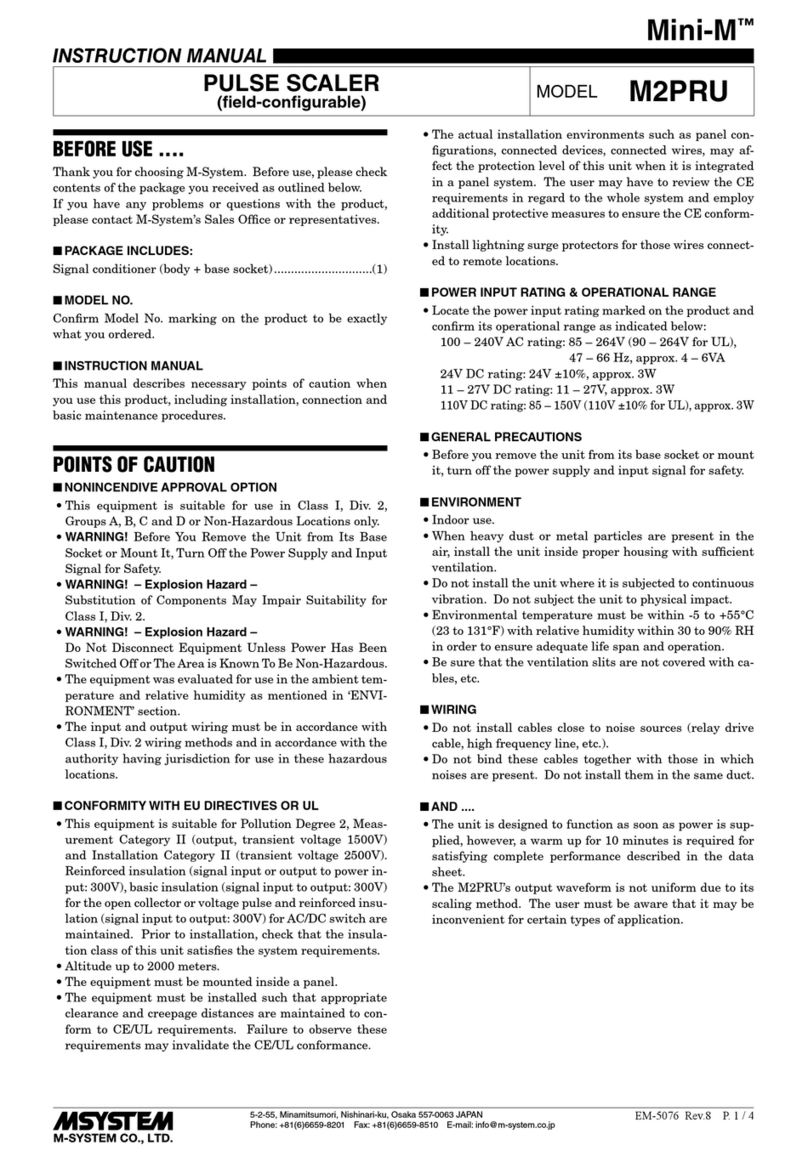

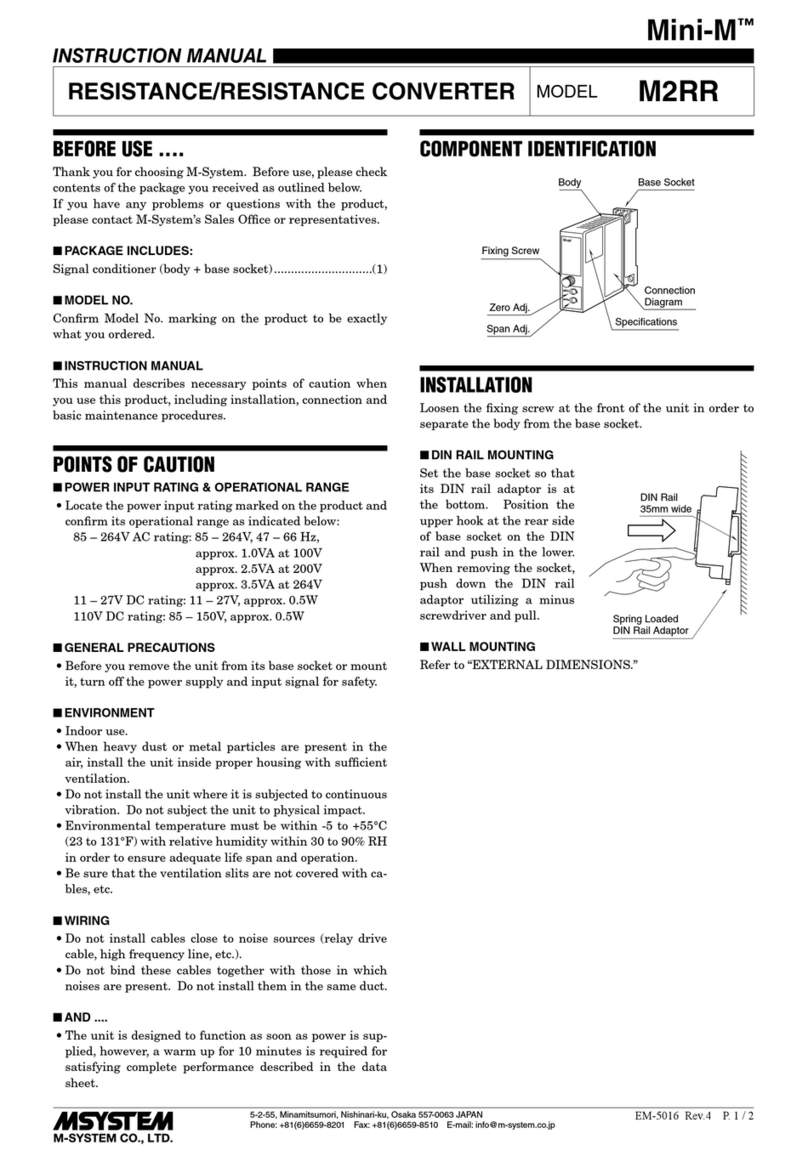

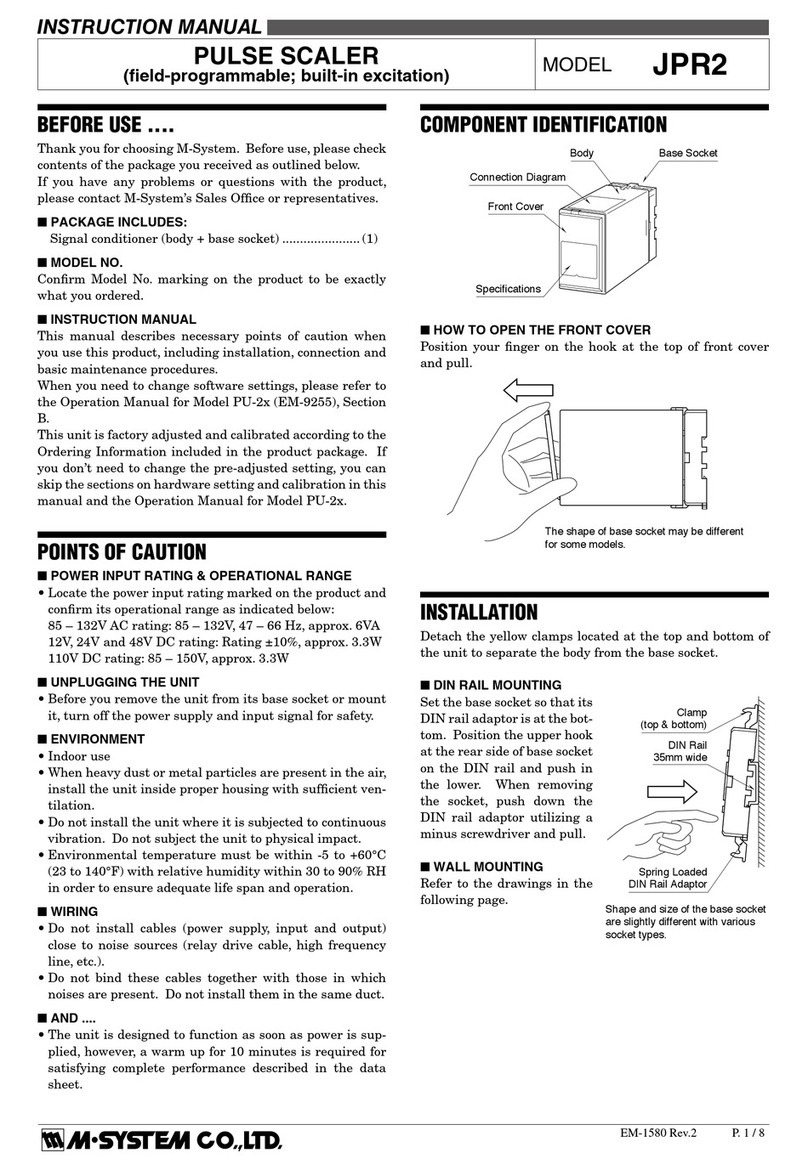

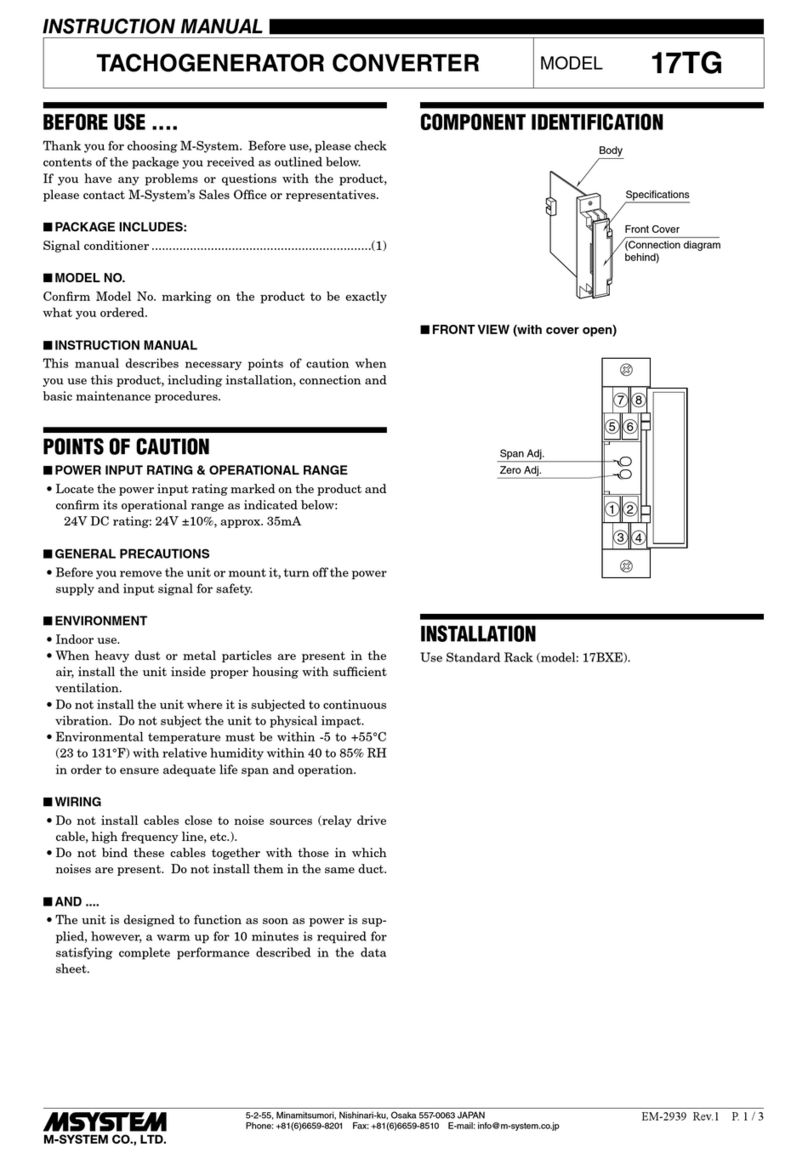

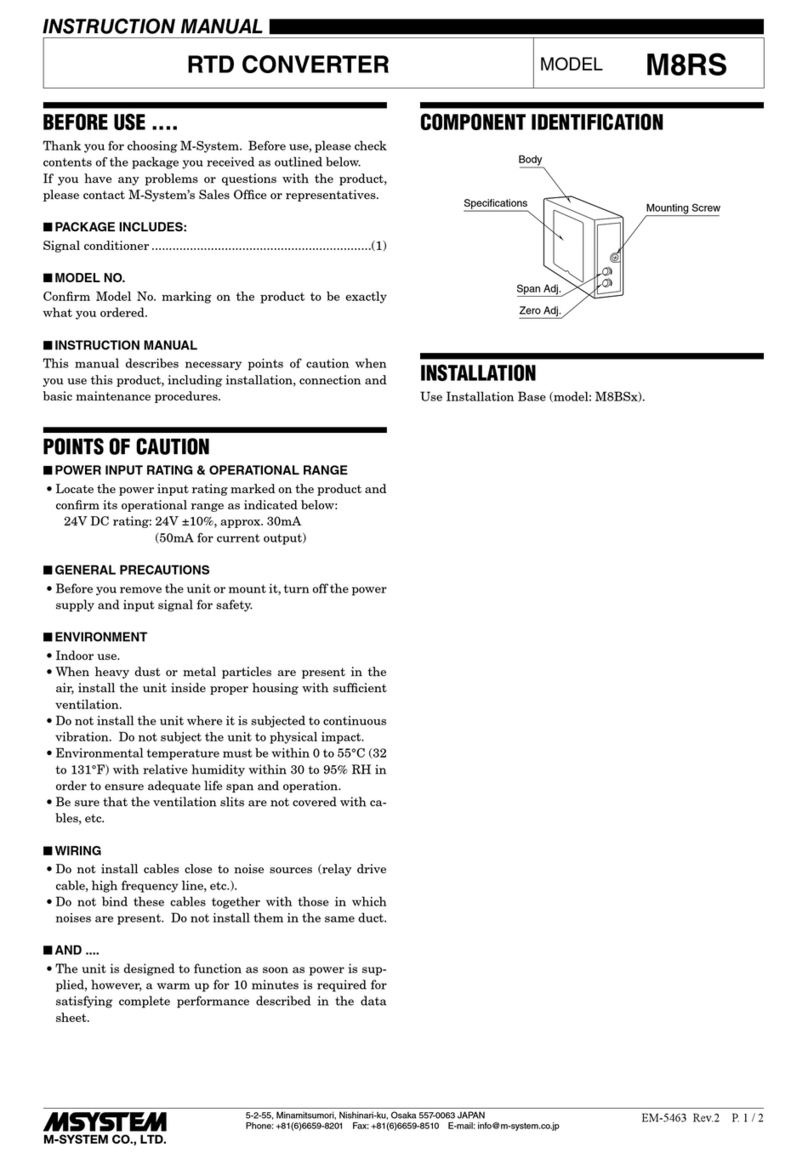

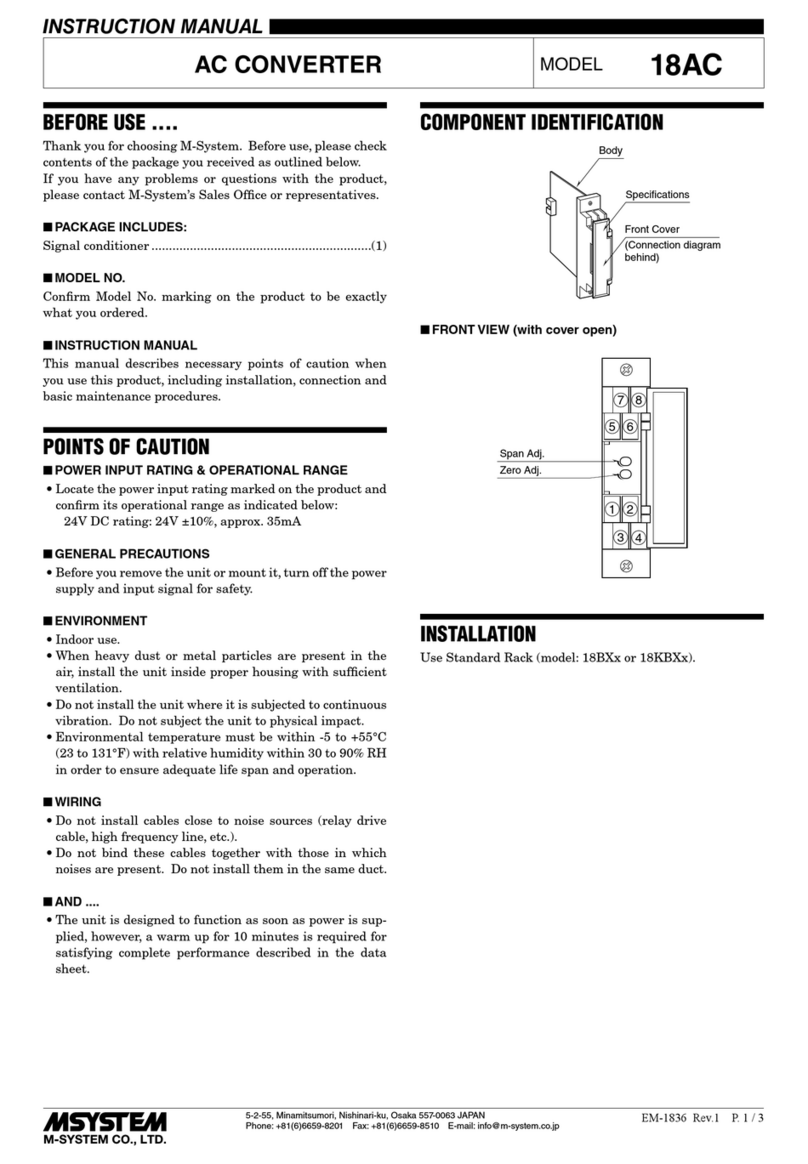

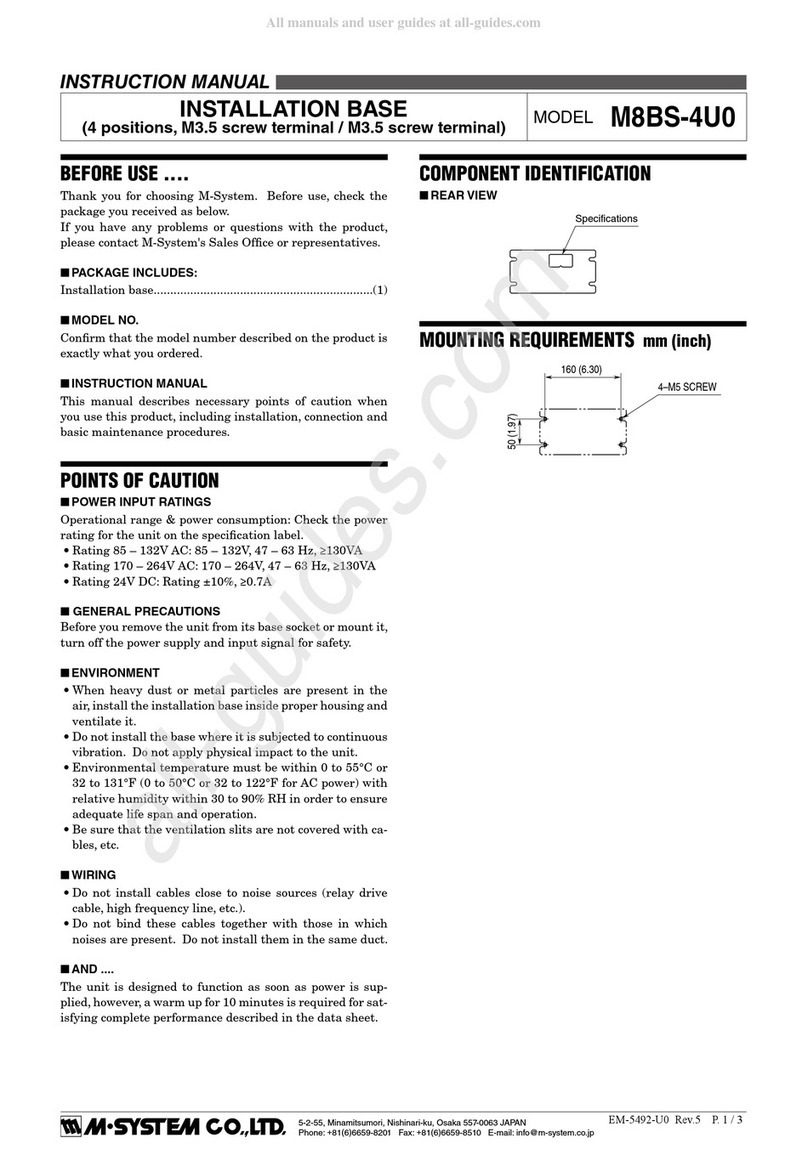

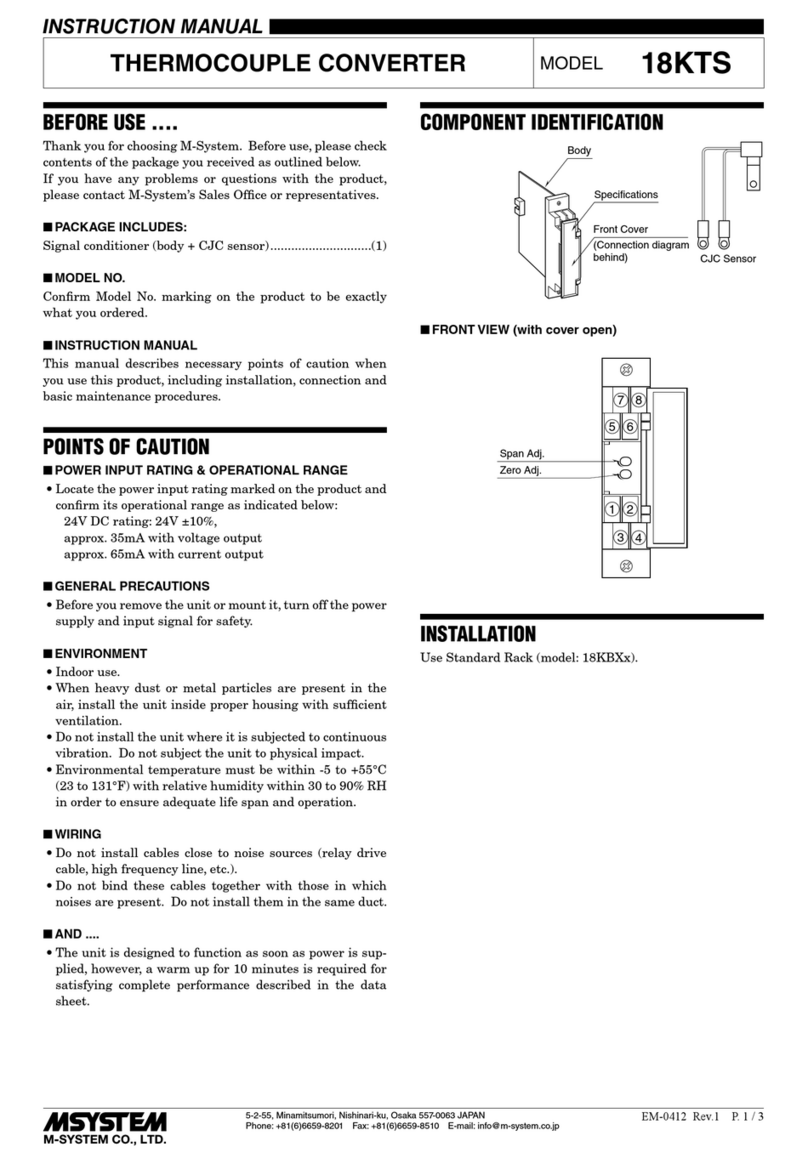

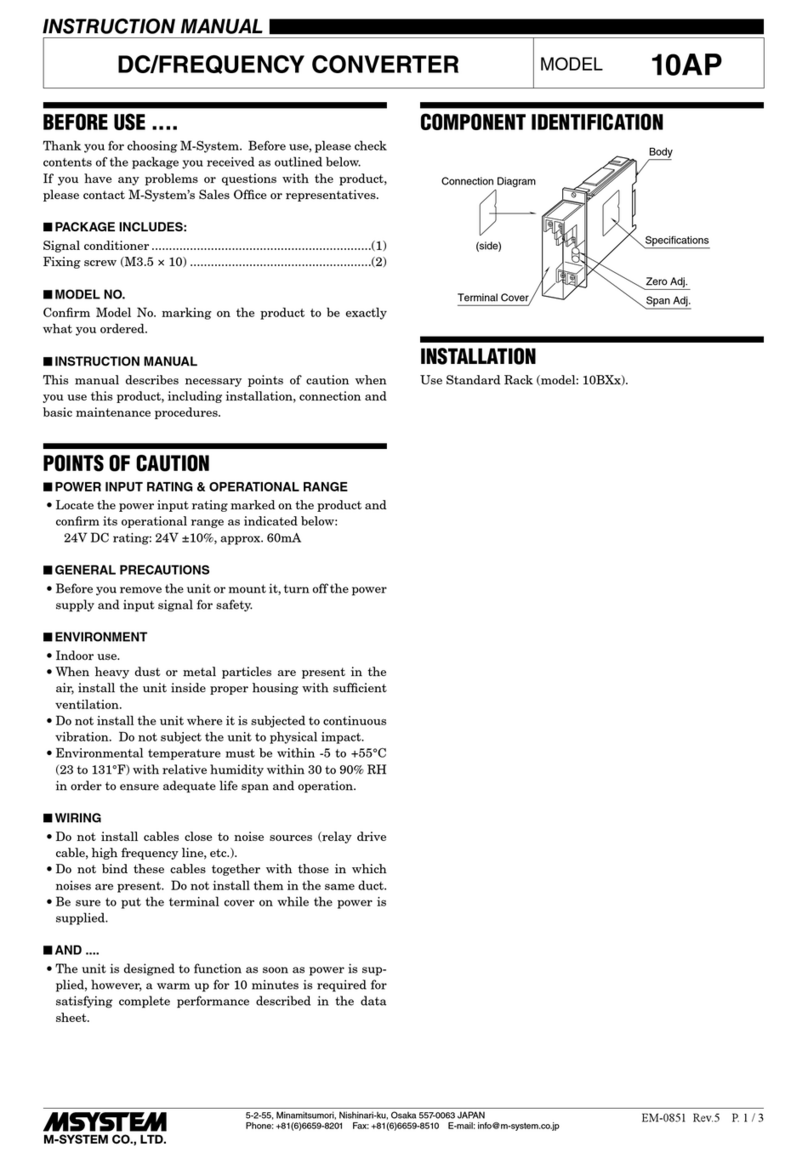

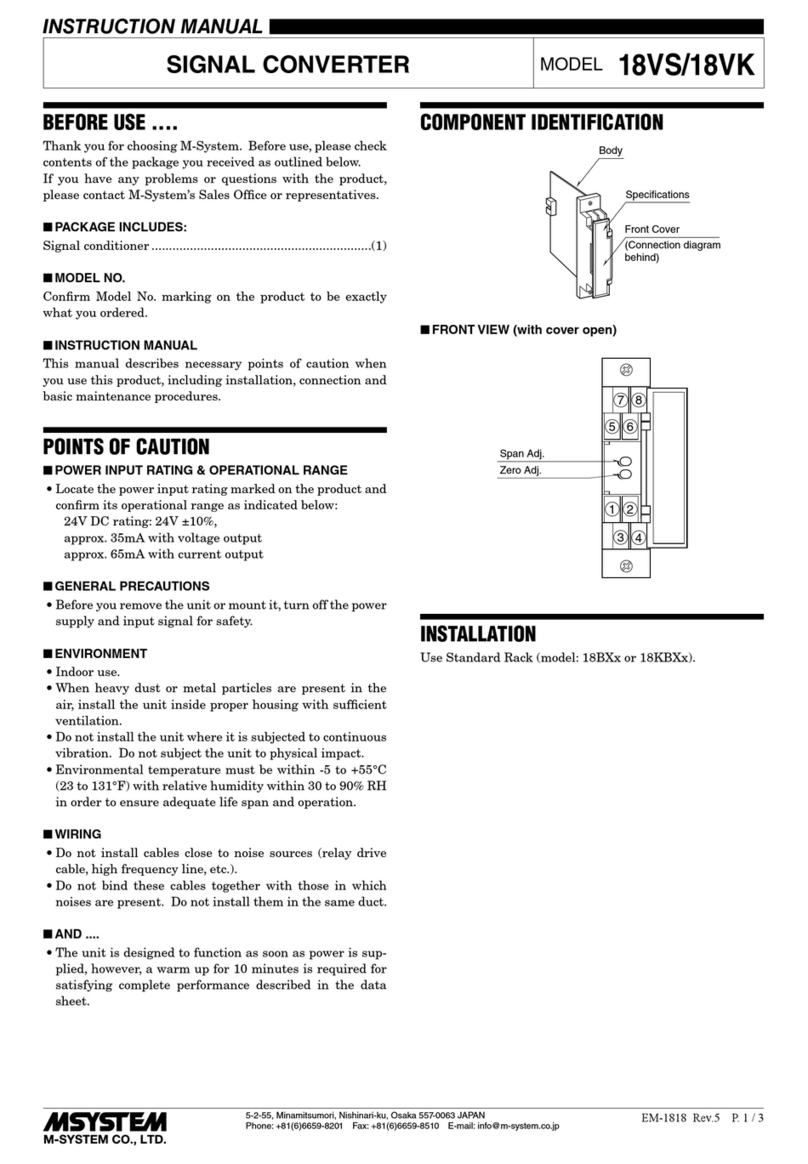

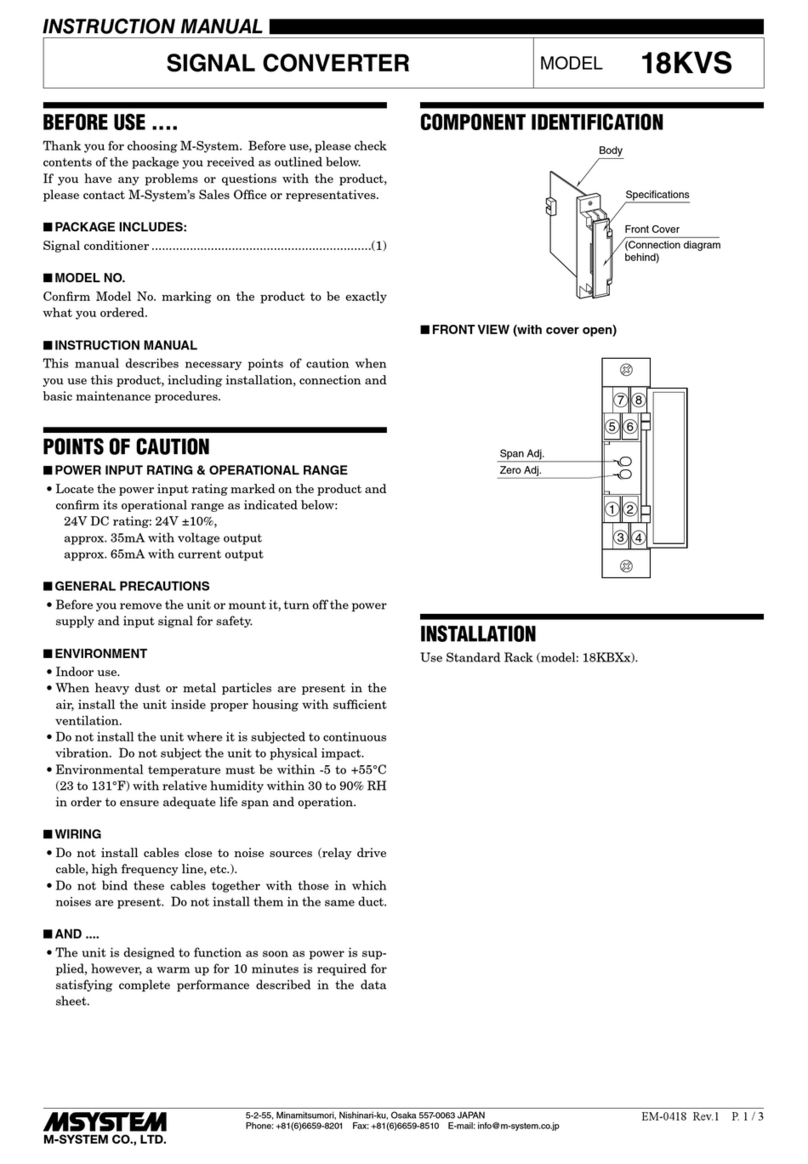

COMPONENT IDENTIFICATION

Body Base Socket

Connection Diagram

Front Cover

Specifications

Input Resistor

■HOW TO OPEN THE FRONT COVER:

Hang your finger on the hook at the top of the front cover

and pull.

The shape of base socket may be different

for some models.

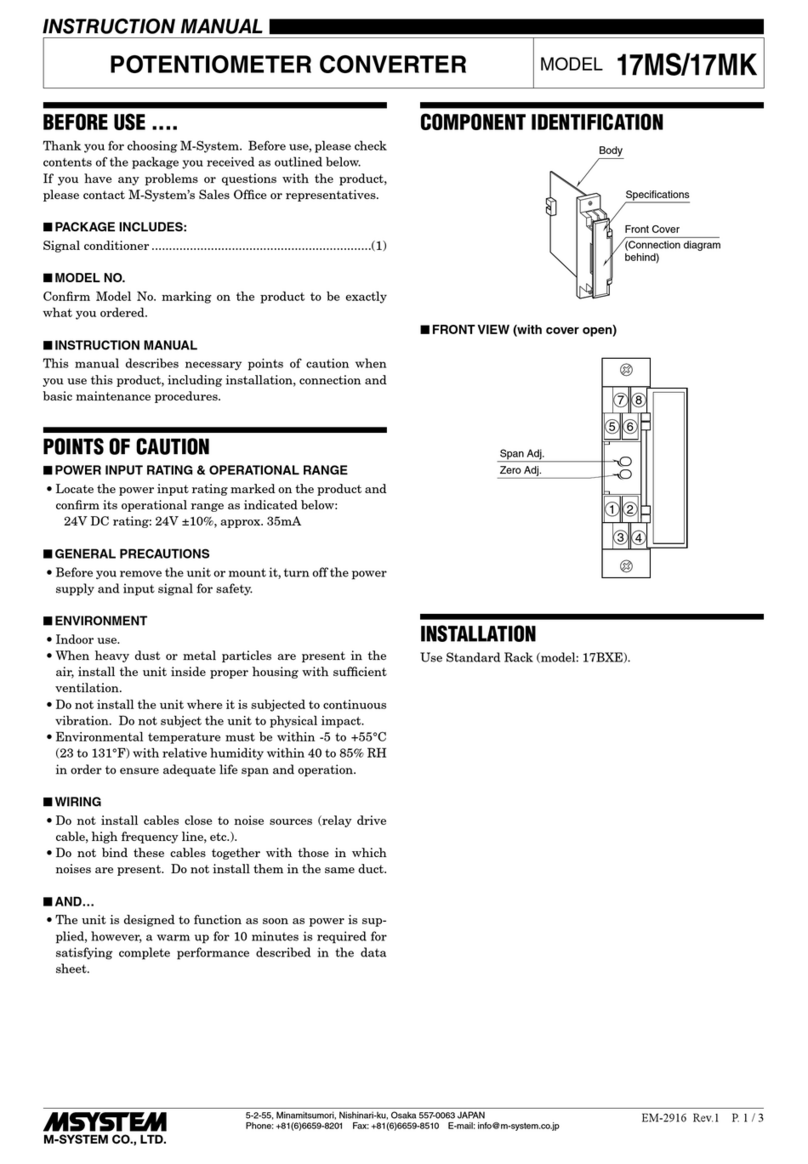

■FRONT PANEL CONFIGURATION

Output Voltage Adj.*

Output Monitor LED B

Modular Jack

Zero Adj.

Span Adj.

Monitor LED (no function)

*only for voltage pulse output

Output Monitor LED A

Note: The output voltage is already adjusted according to the

ordering information sheet. Do NOT change the Output

Voltage .

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1570 Rev.2 P. 1 / 4

INSTRUCTION MANUAL