JPR2

P. 8 / 8EM-1580 Rev.2

M-SYSTEM WARRANTY

M-SystemwarrantssuchnewM-Systemproductwhichitmanufacturestobefreefromdefectsinmaterialsandworkmanshipduringthe36-monthperiodfollowingthedatethatsuch

productwasoriginallypurchasedifsuchproducthasbeenusedundernormaloperatingconditionsandproperlymaintained,M-System’ssoleliability,andpurchaser’sexclusive

remedies,underthiswarrantyare,atM-System’soption,therepair,replacementorrefundofthepurchasepriceofanyM-Systemproductwhichisdefectiveunderthetermsofthis

warranty.Tosubmitaclaimunderthiswarranty,thepurchasermustreturn,atitsexpense,thedefectiveM-Systemproducttothebelowaddresstogetherwithacopyofitsoriginal

salesinvoice.

THISISTHEONLYWARRANTYAPPLICABLETOM-SYSTEMPRODUCTANDISINLIEUOFALLOTHERWARRANTIES,EXPRESSORIMPLIED,INCLUDINGANYIMPLIED

WARRANTIESOFMERCHANTABILITYORFITNESSFORAPARTICULARPURPOSE.M-SYSTEMSHALLHAVENOLIABILITYFORCONSEQUENTIAL,INCIDENTALOR

SPECIALDAMAGESOFANYKINDWHATSOEVER.

M-SystemCo.,Ltd.,5-2-55,Minamitsumori,Nishinari-ku,Osaka557-0063JAPAN,Phone:(06)6659-8201,Fax:(06)6659-8510,E-mail:

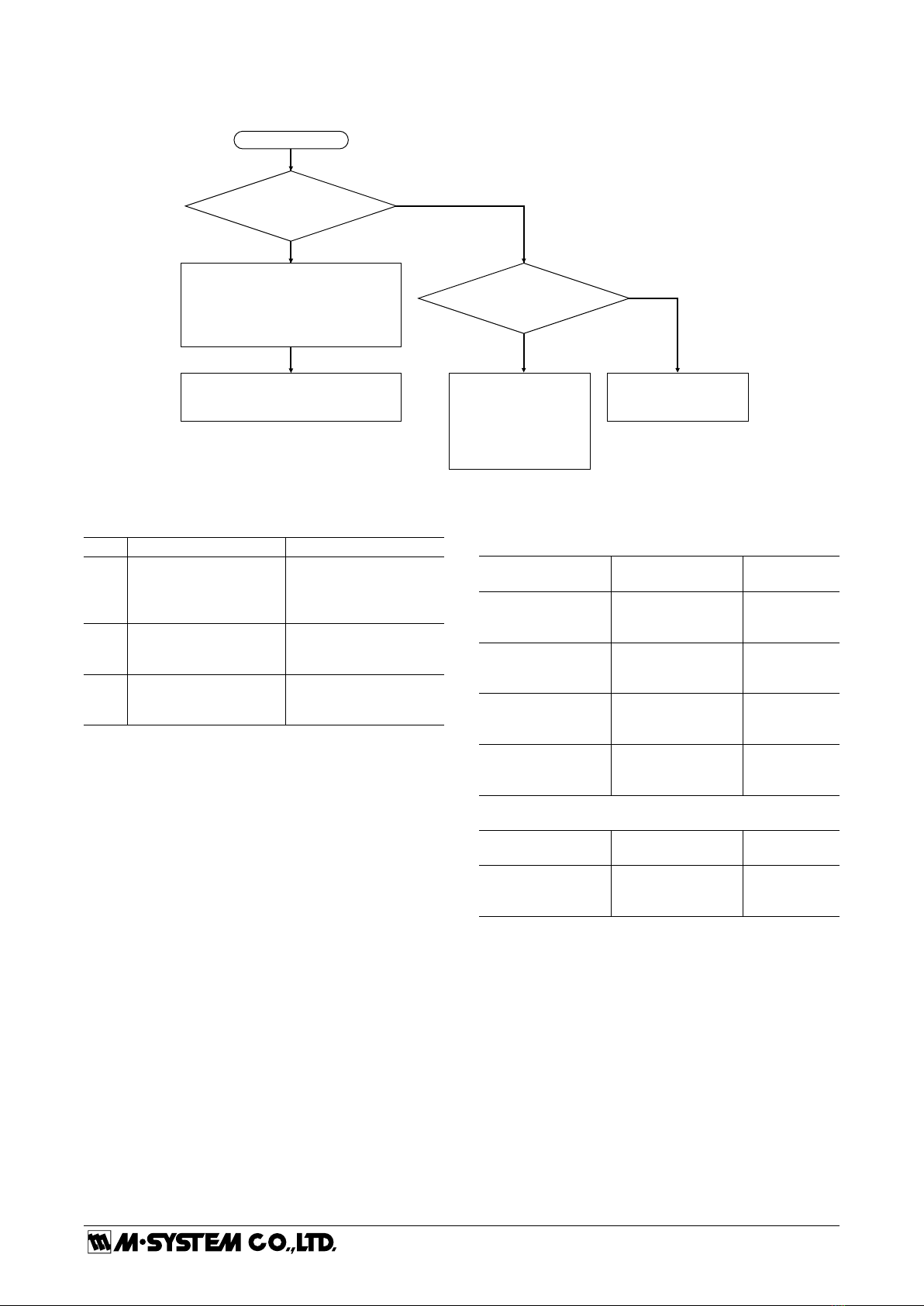

[email protected]SOFTWARE SETTING

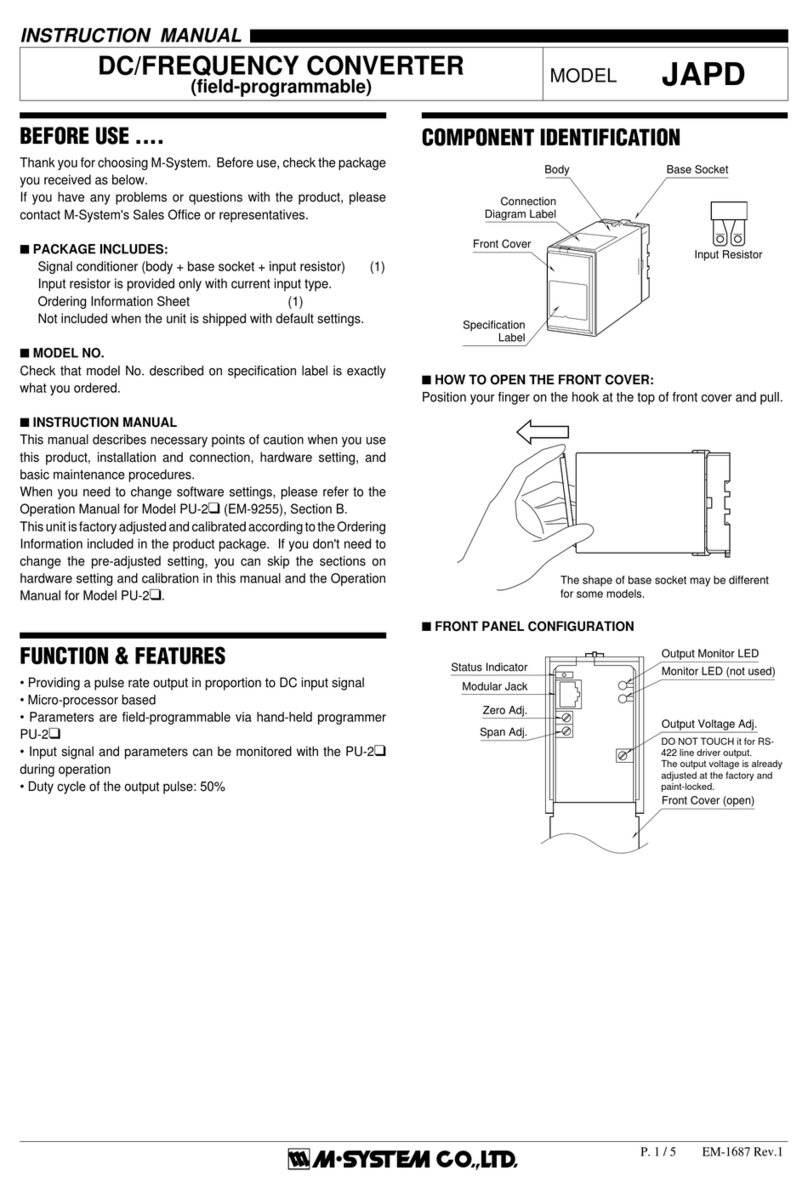

Please refer to the Operation Manual for Model PU-2x (EM-9255), Section B: (B-1) Introduction, (B-2) General Operation

Description, (B-3) Operation Flowchart for general information.

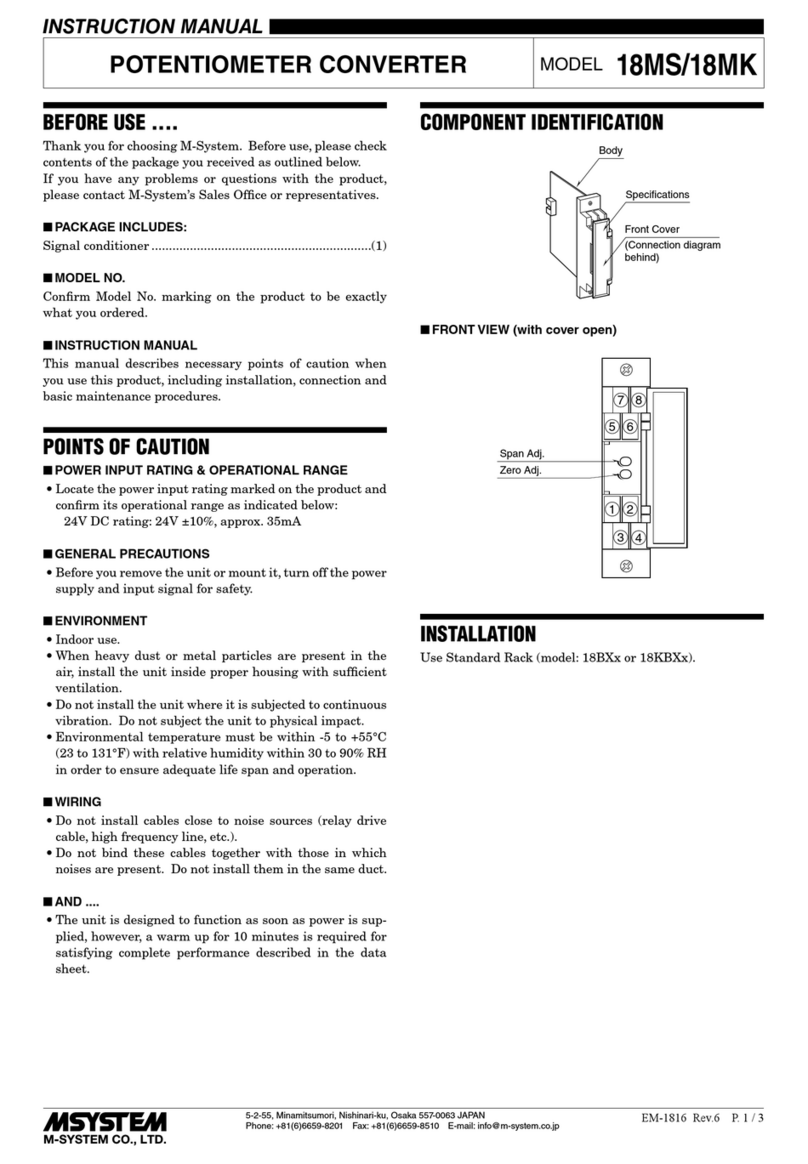

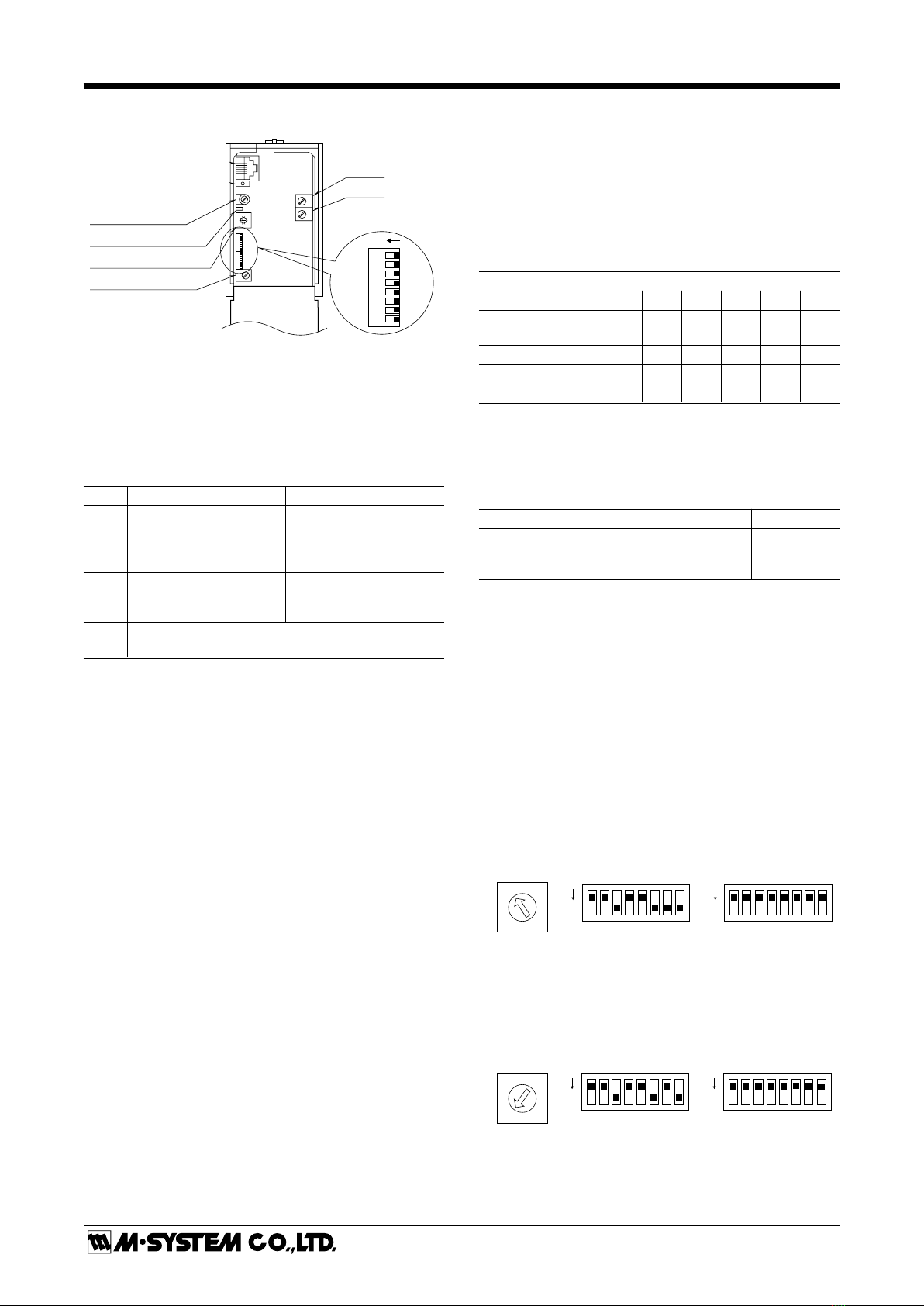

CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

7 – 8 with a multimeter.

3) Check the input signal.

4) Check the output signal.

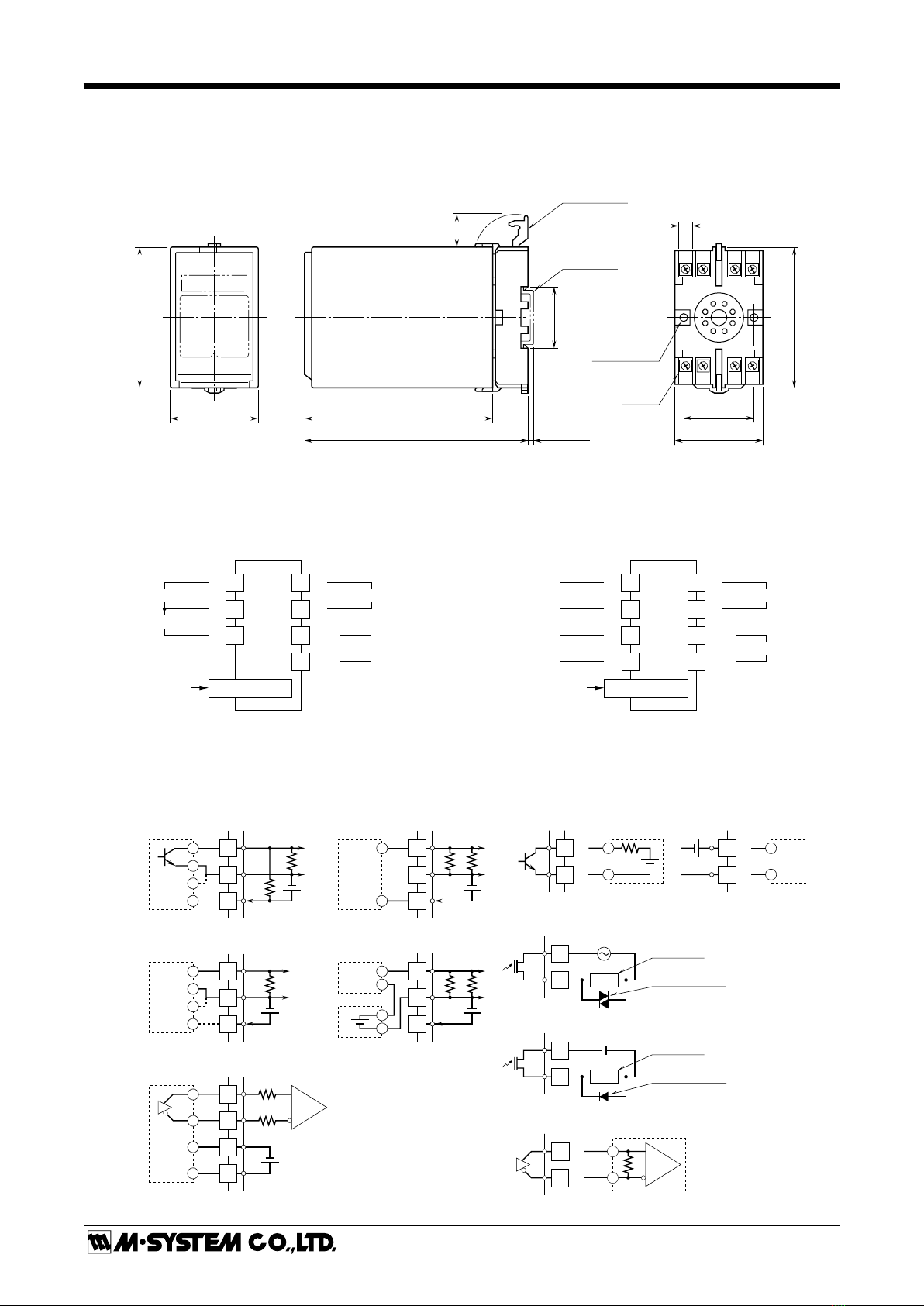

[GROUP01]

ITEM

MDF.

INPUTDATA EXAMPLE(EXAMPLE) DEFAULT CONTENTS

CODE

01 S N/A MAINTENANCE SWITCH

0 MTSW : MON.MODE 0 : Data indication only.

1 MTSW : PRG.MODE 1 : All ‘P’ marked parameters are modifiable.

02 P Alphanumeric TG : XXXXXXXXXX N/A Tag name entry (10 characters max.)

03 P Numeric CNT : XXXXXX 0 Total input pulses (any count selectable)

04 P Numeric IN : XXXXXX 1 Input pulse set count (1 to 1 000 000)

05 P Numeric OUT : XXXXXX 1 Output pulse set count (1 to 1 000 000)

06 P Numeric (Hz) FRQ : XXXX.XHz 10.0 Max. output frequency limit (0.5 to 100000.0 Hz)

07 P Numeric (s) SMP : X.XXs 0.10 Sampling time (0.01 to 100.00 s)

08 D No input N/A

Input specification selected with the front rotary switch

SW : IN_V 1/20 SW = 0, Voltage input, Sensitivity scale = 1/20

SW : IN_V 1/10 SW = 1, Voltage input, Sensitivity scale = 1/10

SW : IN_V 1/5 SW = 2, Voltage input, Sensitivity scale = 1/5

SW : IN_V 1/2 SW = 3, Voltage input, Sensitivity scale = 1/2

SW : IN_V 1/1 SW = 4, Voltage input, Sensitivity scale = 1/1

SW : IN_V 5/1 SW = 5, Voltage input, Sensitivity scale = 5/1

SW : IN_V 10/1 SW = 6, Voltage input, Sensitivity scale = 10/1

SW : IN_OC, mA SW = 7, Open collector, mechanical contact or two-wire

current input

SW : no use SW = 8, (not used)

SW : no use SW = 9, (not used)

SW : IN_RS422 DIP switch set to RS-422 line driver pulse

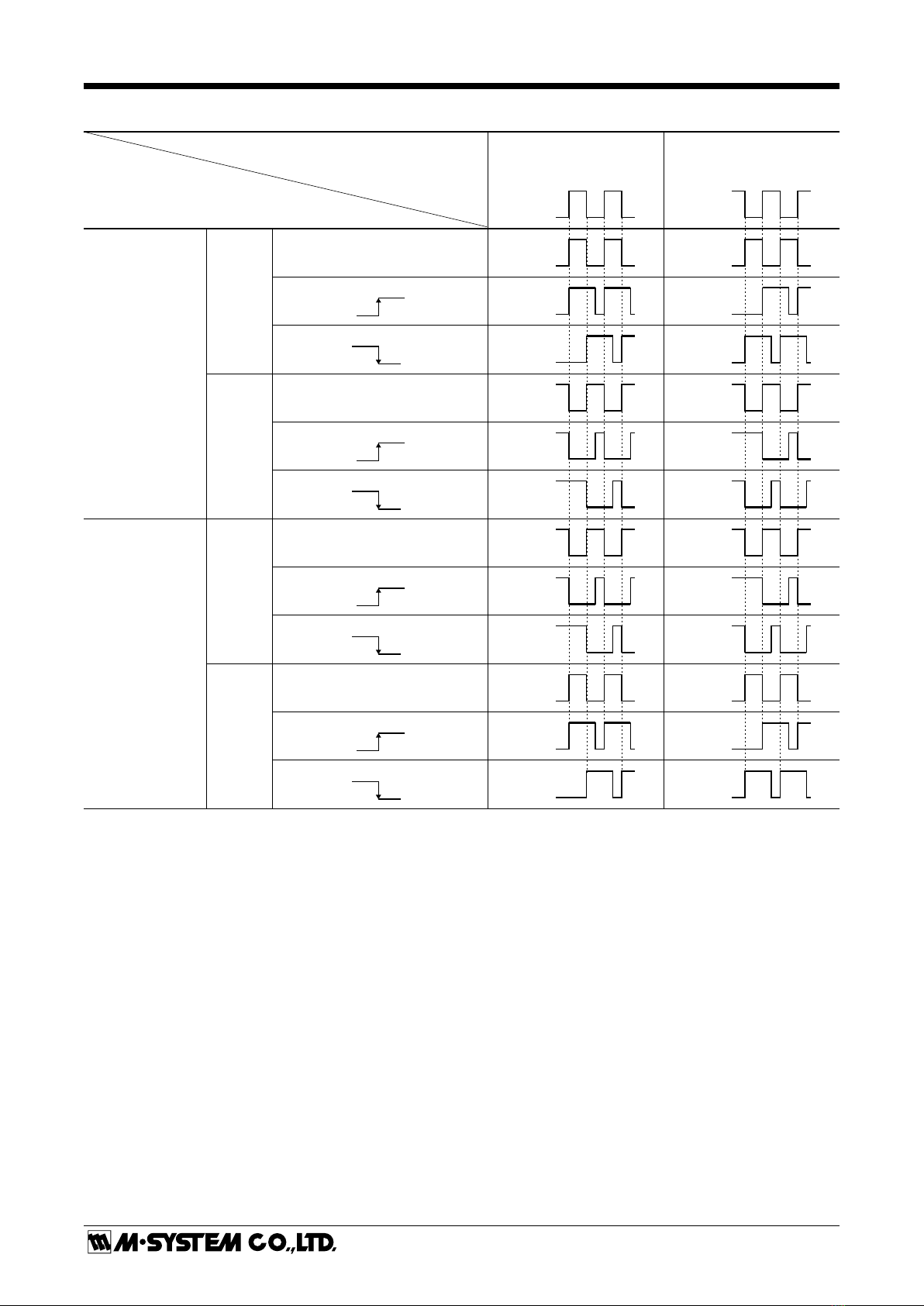

09 P * Count mode

*Factory default depends upon other specifications.

0 IN_EDGE : 0 Count at pulse rise

1 IN_EDGE : 1 Count at pulse sink

Modication Code

D: No modification (writing) possible. Used only for monitoring (reading).

S: Modifiable at any time.

P: Modifiable only when the MAINTENANCE SWITCH is in the ‘PRG’ mode.

ROM Version Indication

[GROUP 00] [ITEM 99]