MXS

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-1739 Rev.4 P. 3 / 7

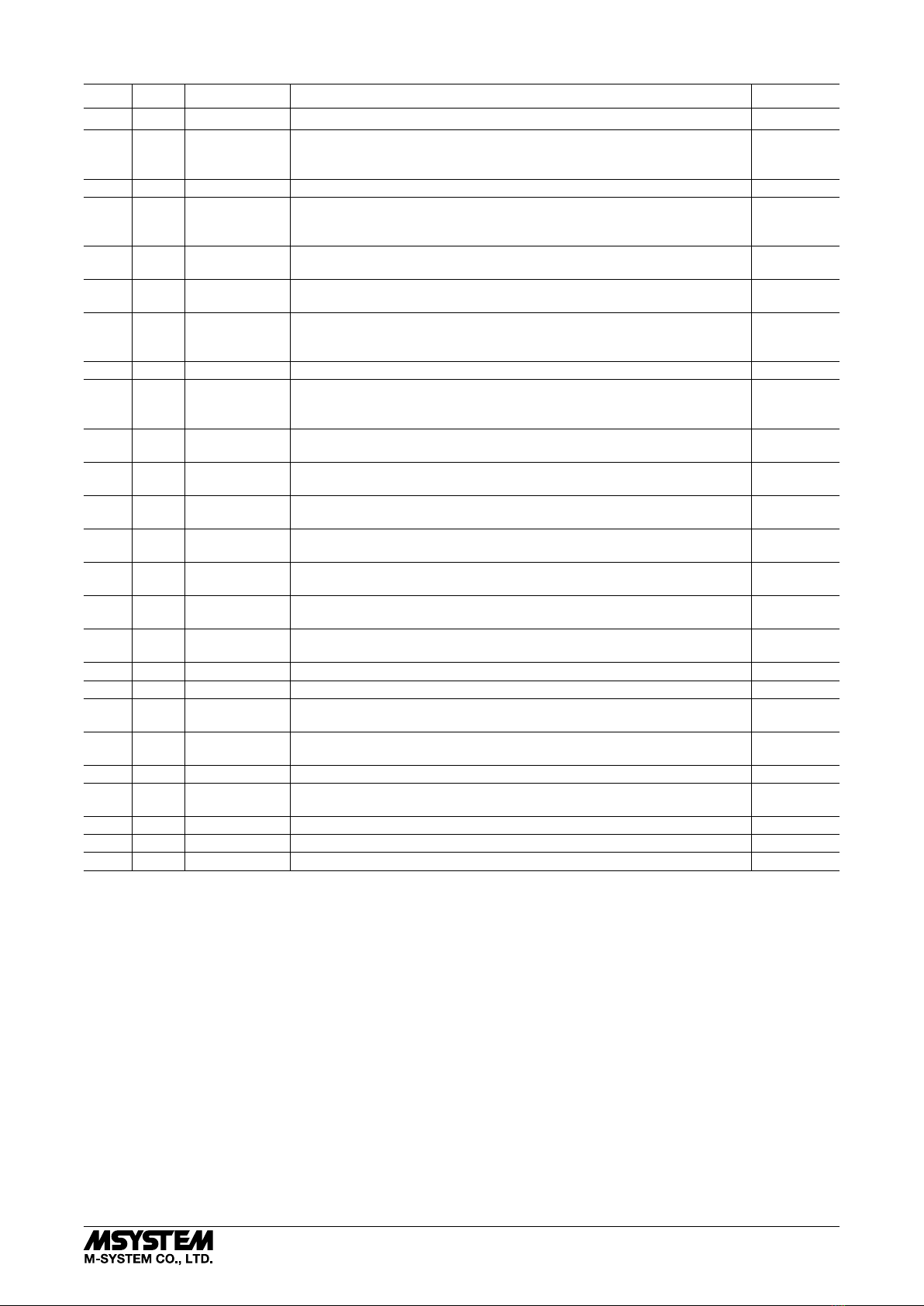

ITEM

MDF.

CODE

DATA CONTENTS DEFAULT

P N/A -180.0 – 360.0 Input display in angle ---

01 1, 2, 3 Modification code 1: Data indication only.

2: All parameters are modifiable.

3: Only ITEM 19 is modifiable.

1

02 N/A 0 – 99 Status indication (“0” is normally indicated.) ---

03

04

2

2

0, 1

0, 1

0° (%) input setting by actual position input *1

100% input setting by actual position input *1

(canceled by ITEM 06 setting)

0

0

05

06

2

2

-180.0 – 180.0

0.0 – 360.0

0° (%) input angle adjustment (fine adj. of the value set in ITEM 03) *2

100% input angle adjustment (canceled by ITEM 04 setting)

0.0

270.0

07 2 0, 1 Rotating direction *3 0: CW (clockwise) *2

1: CCW (counterclockwise)

0

08 N/A 0, 1, 2 Output range code 0: V1 (-1 – +1V)

1: V2 (-10 – +10V)

2: Z1 (0 – 20mA)

V1: 0

V2: 1

Z1: 2

09 N/A -15.0 – 115.0 Input indicated in % (of the range set in ITEM 03/04/05/06) ---

10/L 2 -15.0 – 115.0 Output indicated in % with ITEM 01 DATA 1 (of the range set in ITEM 17/18)

Loop test output with ITEM 01 DATA 2 (‘L’ is indicated as ITEM No.)

(Use DATA UP/DOWN key to set the output signal.)

---

11

12

2

2

-99.99 – 99.99

-99.99 – 99.99

Output zero adjustment (%) (fine adj. of the value set in ITEM 17)

Output span adjustment (%) (fine adj. of the value set in ITEM 18)

0.00

0.00

13 2 0, 1, 2, 3, 4 Moving average (sampling cycle: 150 msec.)

0: No 1: 4 samples 2: 8 samples 3: 16 samples 4: 32 samples

0

14 2 0, 1 – 60 Power-saving mode 0: Continuous display

1 – 60: Time before display turned off (minutes)

10

15

16

2

2

-15.0 – 0.0

100.0 – 115.0

Overrange output below 0%

Overrange output exceeding 100%

-15.0

115.0

17

18

2

2

-1.00 – 1.00

-1.00 – 1.00

Output code V1 0% output voltage (V) *4

100% output voltage (V) *4

-1.00

1.00

17

18

2

2

-10.0 – 10.0

-10.0 – 10.0

Output code V2 0% output voltage (V) *4

100% output voltage (V) *4

-10.0

10.0

17

18

2

2

0.0 – 20.0

0.0 – 20.0

Output code Z1 0% output current (mA) *4

100% output current (mA) *4

4.0

20.0

19 N/A --- --- ---

20 2 0, 1 Linearization table 0: Disable 1: Enable *50

21

22

2

2

-15.0 – 115.0

-15.0 – 115.0

Point 1 input setting (%)

Point 1 output setting (%)

0.0

0.0

23

24

2

2

-15.0 – 115.0

-15.0 – 115.0

Point 2 input setting (%)

Point 2 output setting (%)

0.0

0.0

: : : : :

83

84

2

2

-15.0 – 115.0

-15.0 – 115.0

Point 32 input setting (%)

Point 32 output setting (%)

0.0

0.0

85 2 0, 1 Inverted output 0: Non-inverted 1: Inverted 0

86 3 0, 1 Reset all settings *60

87 N/A --- ROM version ---

*1. Press DATA UP key and choose DATA 1. Double-click DATA DOWN key. The display shows DATA 0 after the setting is com-

plete.

*2. Relative to absolute 0° for the device which is determined with the 0° (%) input setting (ITEM 03).

*3. Rotating direction (ITEM 07) must be determined before setting the 0° (%) input setting (ITEM 03).

*4. ITEM 17 < ITEM 18.

*5. Linearization is disabled with the loop test output.

*6. Press DATA UP key and choose DATA 1. Double-click DATA DOWN key. The display shows DATA 0 after the initialization is

complete.