M6SCTC

P. 1 / 4EM-7972 Rev.4

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

■WIRING

•Do not install cables close to noise sources (relay drive

cable,highfrequencyline,etc.).

•Do not bind these cables together with those in which

noisesarepresent.Donotinstalltheminthesameduct.

■AND ....

The unit is designed to function as soon as power is sup-

plied,however,awarmupfor10minutesisrequiredforsat-

isfyingcompleteperformancedescribedinthedatasheet.

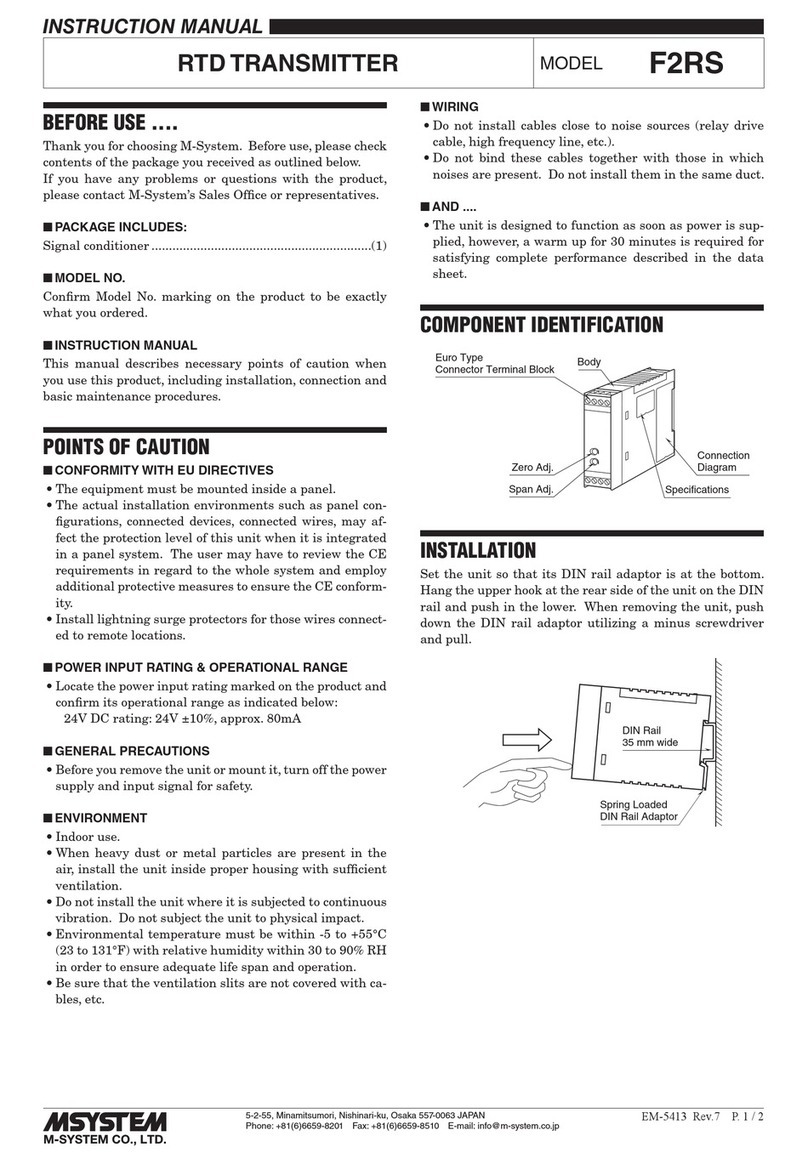

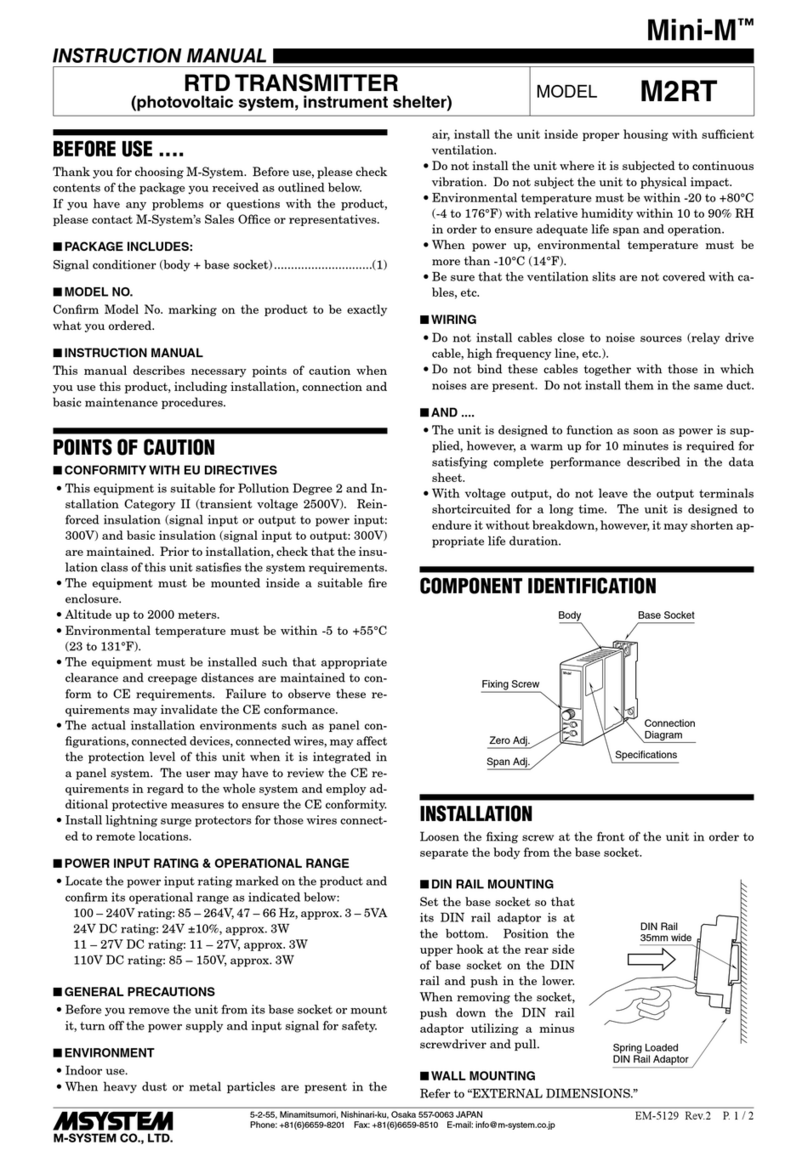

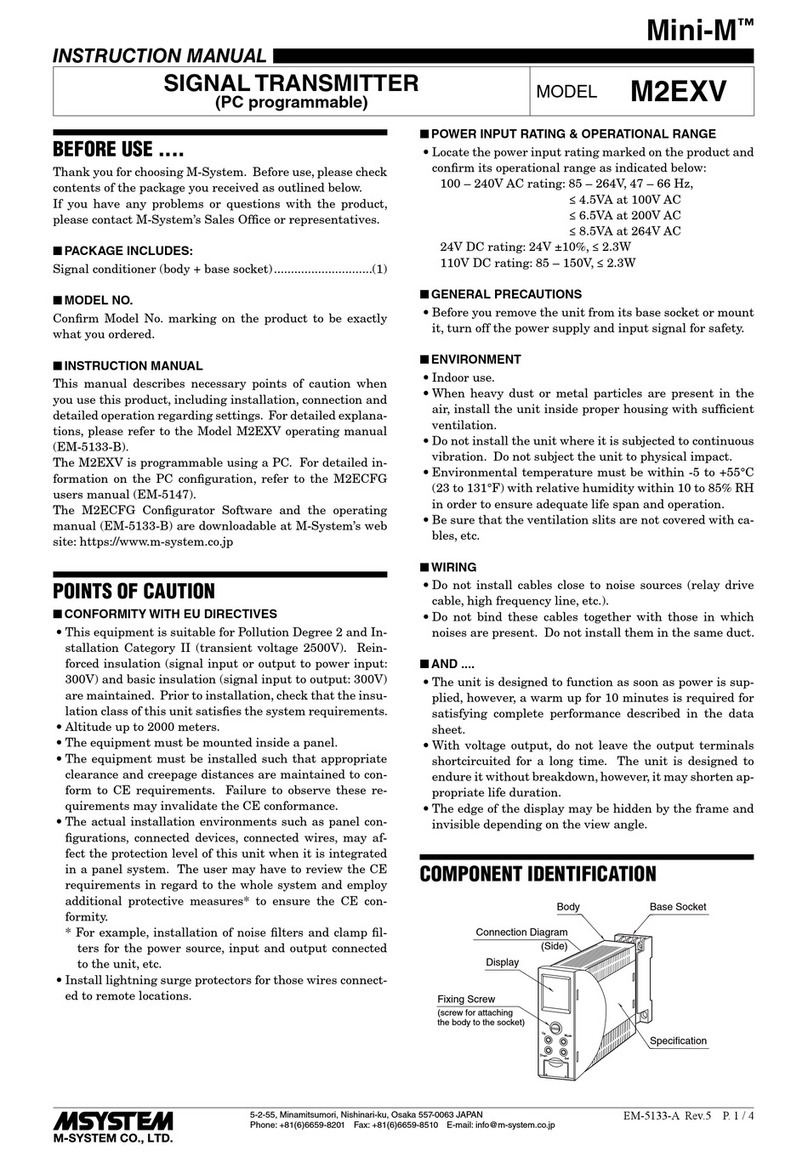

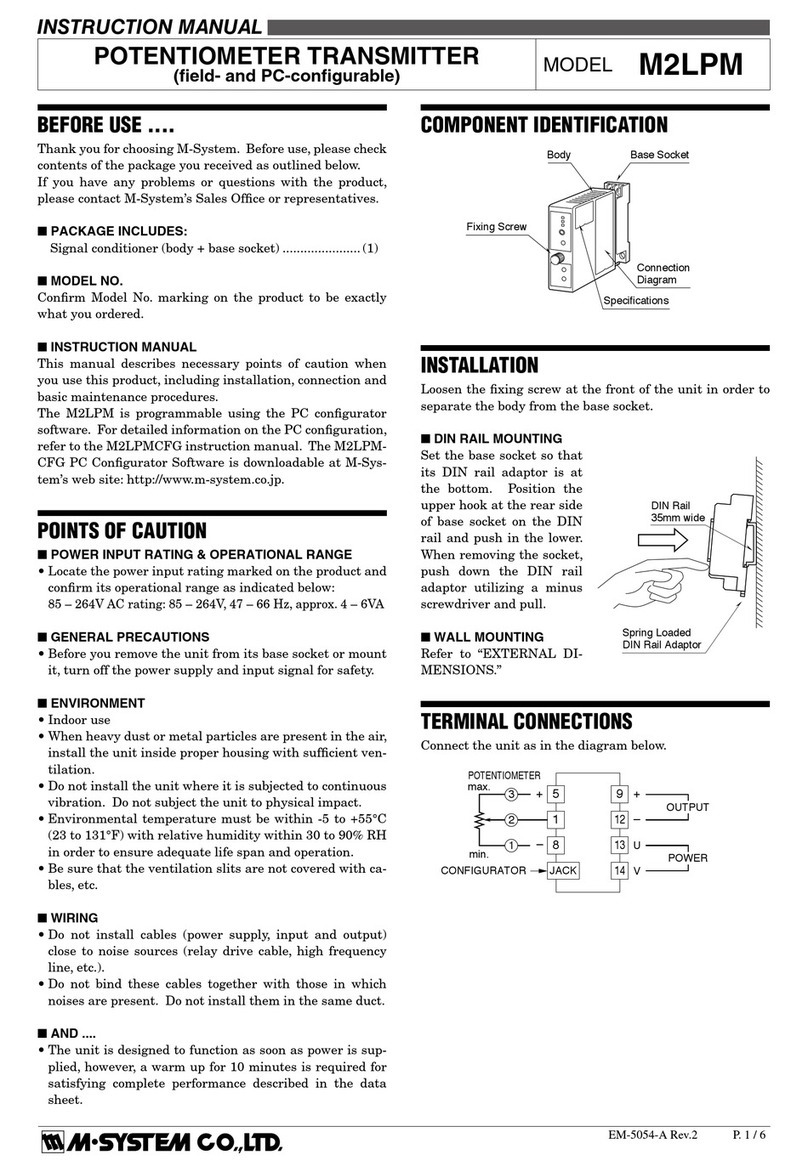

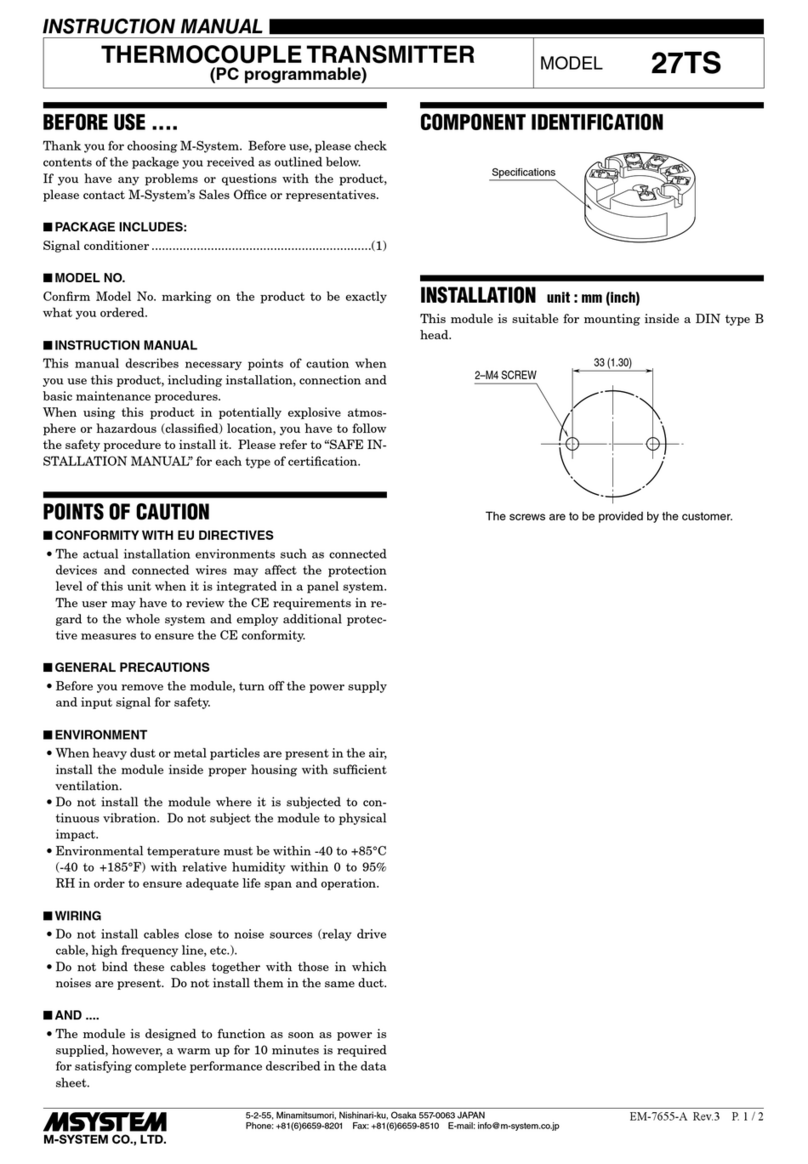

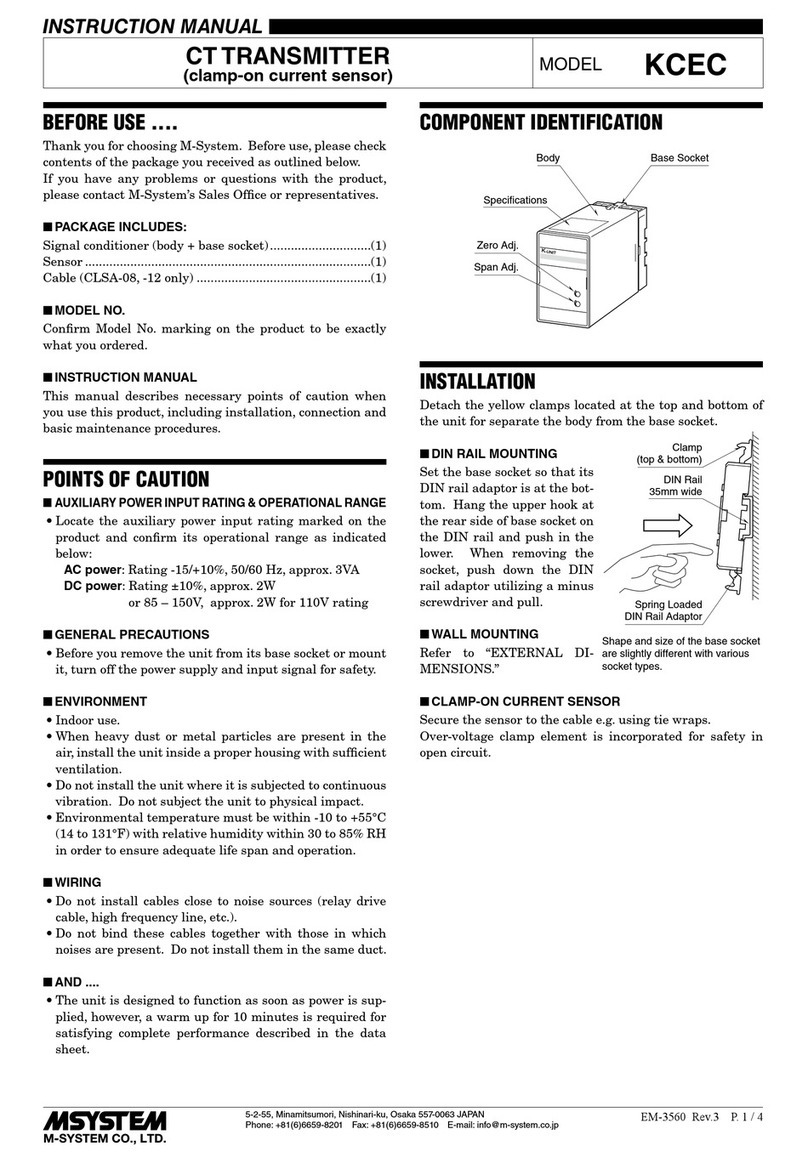

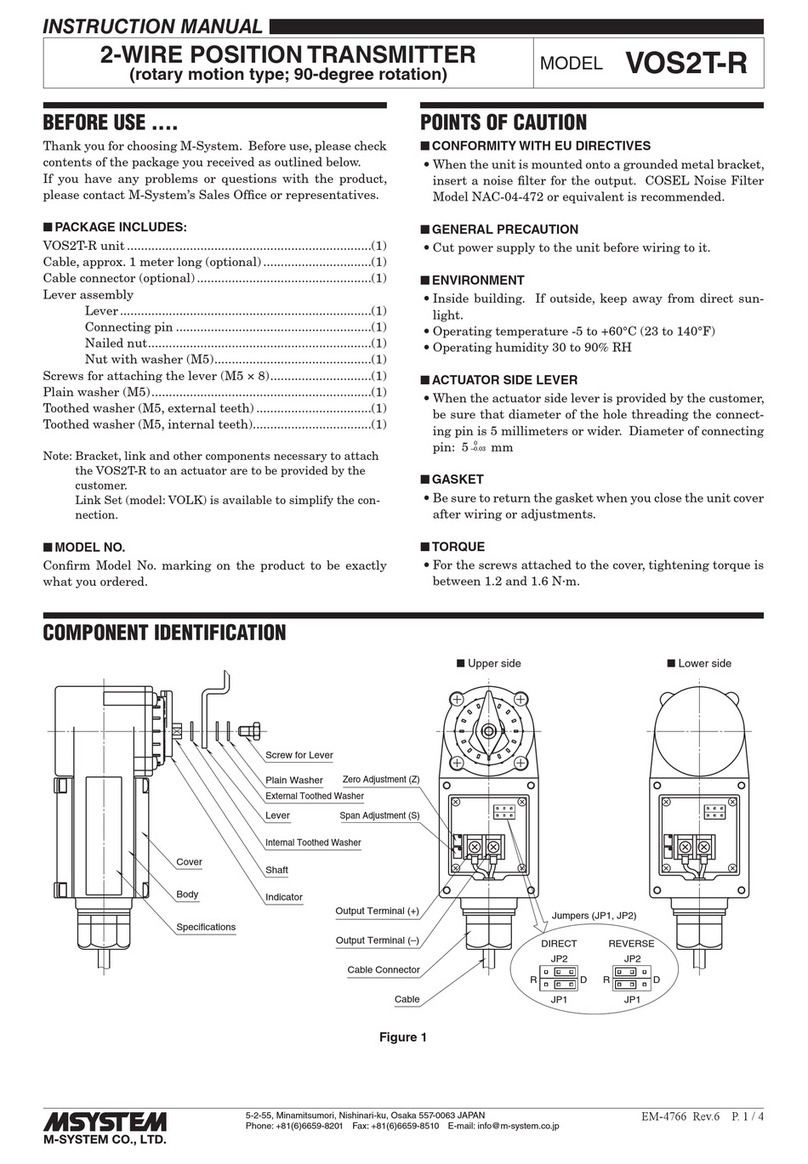

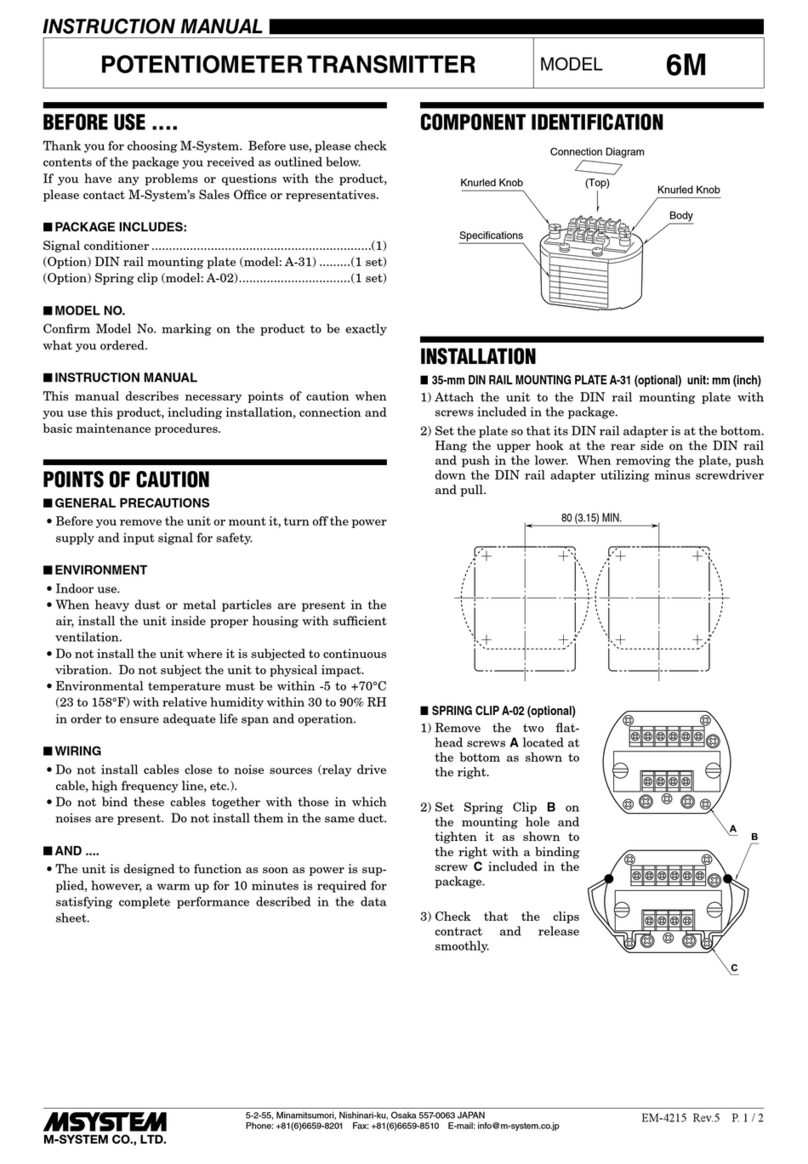

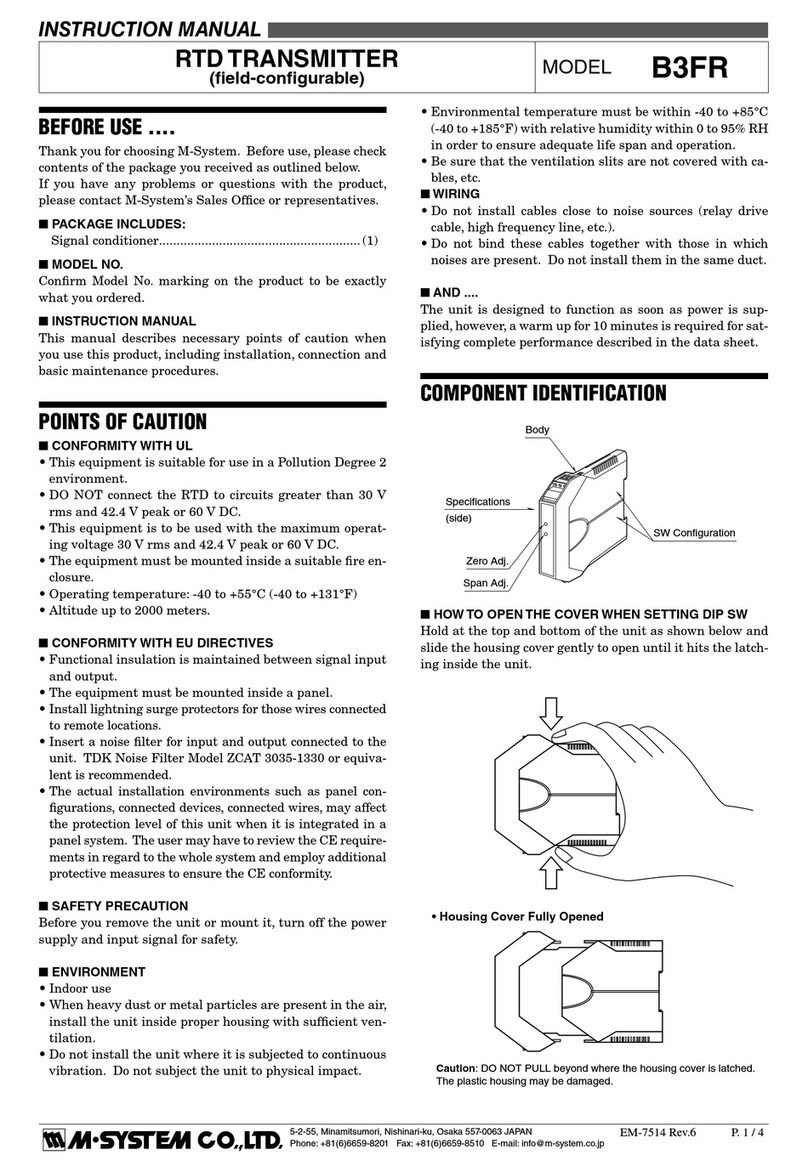

COMPONENT IDENTIFICATION

■FRONT PANEL CONFIGURATION (with the cover open)

Zero Adj.

Power LED

Span Adj.

CT TRANSMITTER

(clamp-on current sensor) MODEL M6SCTC

INSTRUCTION MANUAL

BEFORE USE ....

ThankyouforchoosingM-System.Beforeuse,pleasecheck

contentsofthepackageyoureceivedasoutlinedbelow.

If you have any problems or questions with the product,

pleasecontactM-System’sSalesOfceorrepresentatives.

■PACKAGE INCLUDES:

Signalconditioner......................................................... (1)

■MODEL NO.

Conrm Model No. marking on the product to be exactly

whatyouordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

youusethisproduct,includinginstallation,connectionand

basicmaintenanceprocedures.

POINTS OF CAUTION

■CONFORMITY WITH EU DIRECTIVES

•Theequipmentmustbemountedinsideapanel.

•UsethecurrentsensorwithM-System’sCLSE-x/CE.

•Theactualinstallationenvironmentssuchaspanelcon-

gurations, connected devices, connected wires, may af-

fecttheprotectionlevelofthisunitwhenitisintegrated

inapanelsystem.TheusermayhavetoreviewtheCE

requirementsinregardtothewholesystemandemploy

additionalprotectivemeasurestoensuretheCEconform-

ity.

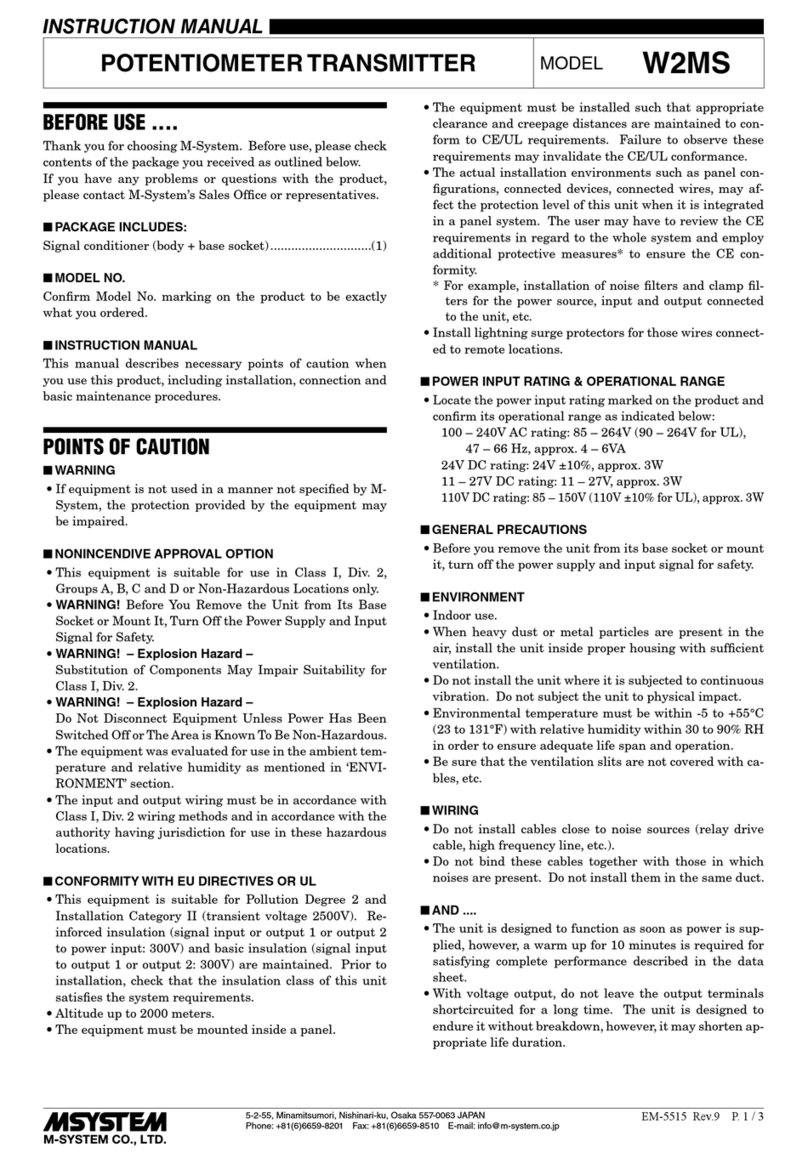

■POWER INPUT RATING & OPERATIONAL RANGE

Locatethepowerinputratingmarkedontheproductand

conrmitsoperationalrangeasindicatedbelow:

24VDCrating:24V±10%,approx.0.5W

■GENERAL PRECAUTIONS

Beforeyouremovetheunitormountit,turnoffthepower

supplyandinputsignalforsafety.

■ENVIRONMENT

•Indooruse

•Whenheavydustormetalparticlesarepresentintheair,

installtheunitinsideproperhousingwithsufcientven-

tilation.

•Donotinstalltheunitwhereitissubjectedtocontinuous

vibration.Donotsubjecttheunittophysicalimpact.

•Environmentaltemperaturemustbewithin-20to+55°C

(-4to+131°F)withrelativehumiditywithin30to90%RH

inordertoensureadequatelifespanandoperation.

■CLAMP-ON CURRENT SENSOR

•Thecurrentsensoristobeorderedseparately.

•Over-voltageclampelementincaseofanopencircuitis

incorporatedforsafety.

•Fixthesensormoduleattheinputcablewithabinding

strap.

Body

Front Cover

DIN Rail Adaptor

Spec. Marking