EH00002 EasyLoad Installation Manual

5

▪MAD is not responsible for the suspension of the EasyLoad to any mounting frame other

than the one supplied by MAD.

▪Have any damage repaired or repairs carried out by a person with the relevant expertise.

The guarantee will be void in the case of unprofessional repairs and modifications to the

EasyLoad.

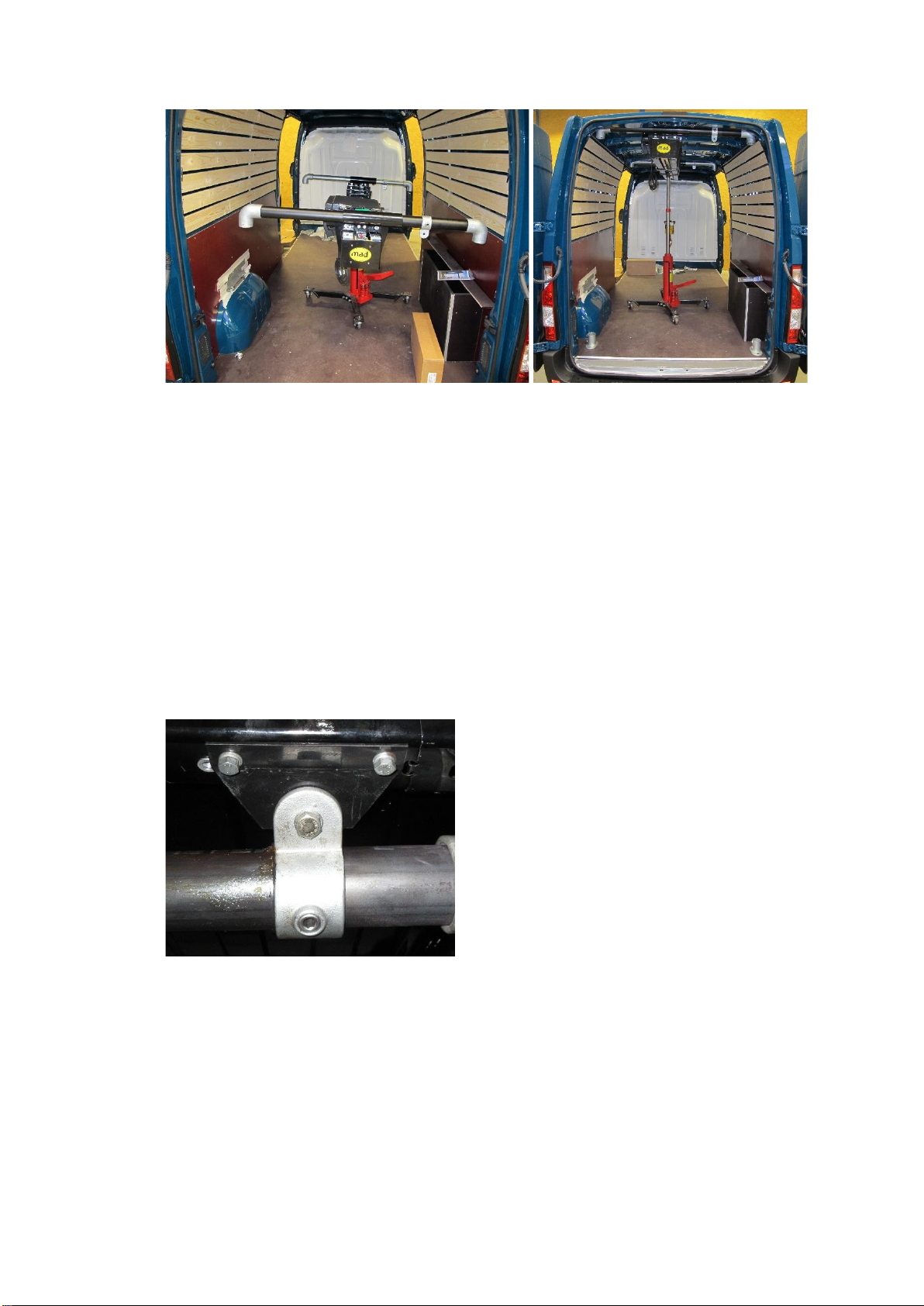

▪Always put the car horizontal, apply the vehicle's parking brake and make sure the load

compartment is completely empty.

▪The weight of the EasyLoad requires that it should be lifted out of and back into the frame

by means of a lifting aid. To do this, use a transmission jack or other lifting device.

▪If such a lift is not available, the EasyLoad should be lifted or moved by at least four

people.

▪Always use straps to prevent injury and/or damage if the EasyLoad is to be lifted in or out

of the frame without a lifting aid. Pull on the tension straps alternately and evenly while

lifting. When lowering, allow the tension straps to slacken simultaneously. In all cases,

keep the EasyLoad horizontal.

▪While installing the EasyLoad, the hoisting cable should always remain under tension by

allowing the weight to hang freely above the lifting hook. This prevents the cable from

kinking and/or running off the guide wheels.

▪Always put the EasyLoad on trestles or two beams and never directly on the ground or

floor of the vehicle. This can result in damage to the hoisting cable.

▪Especially for electric vehicles, ensure that the car manufacturer's installation guidelines

are followed in the areas of the battery pack and electrical wiring.

▪When drilling in the vehicle, look out for wires which may be located behind a panel. If

there are any, divert them temporarily.

▪Remove any sharp edges after drilling and apply an anti-corrosion agent.

▪Also make sure that the wiring is not pinched or can be damaged when screwing in a bolt.

3 The frame

3.1 General points of attention

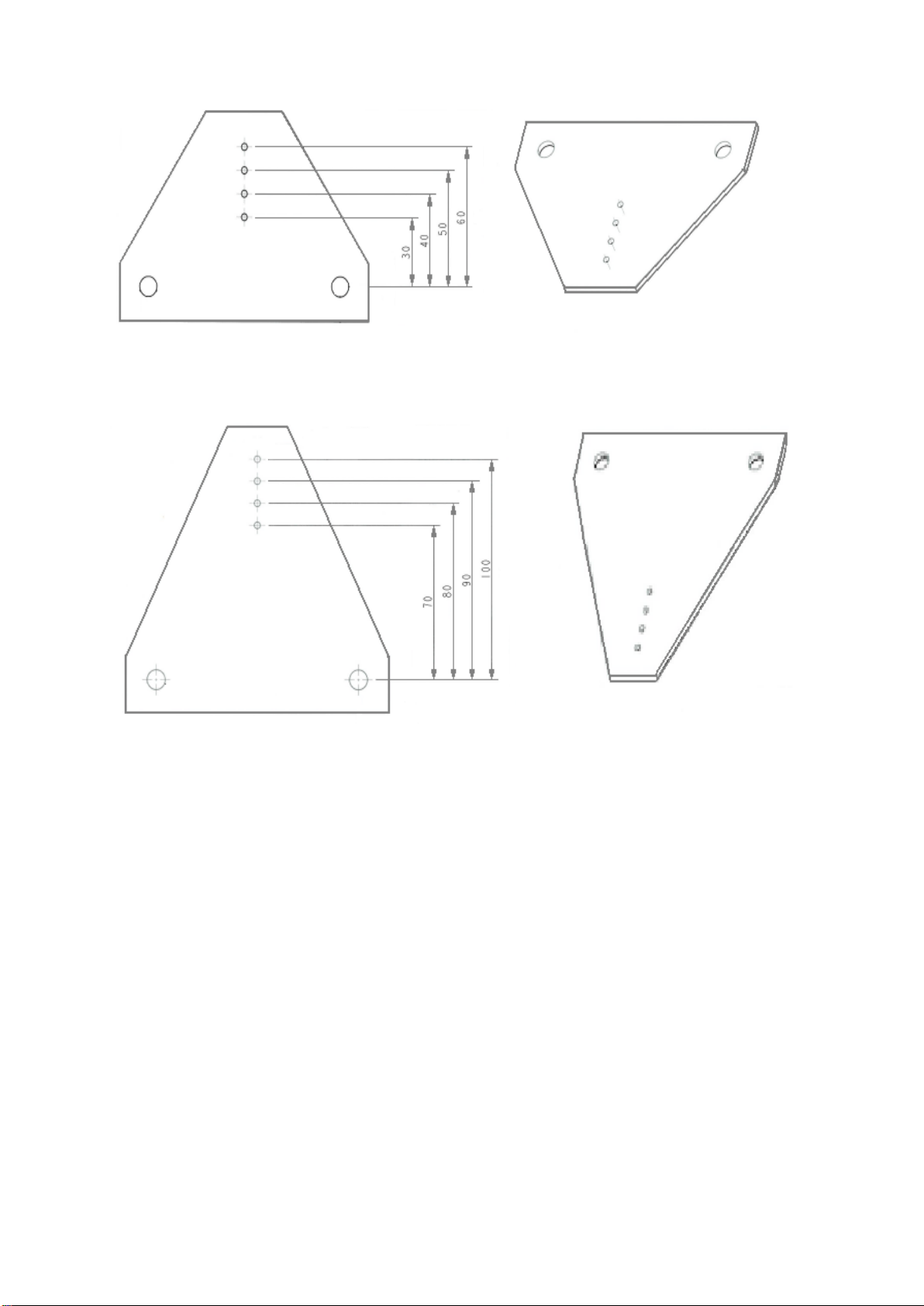

A marking must be placed on the uprights of the frame. This marking can be used to determine

whether the upright has been inserted far enough into the coupling. If the length of the frame

uprights needs to be adjusted, apply a new marking after sawing. A stripe or scratch must be

placed as a marking at a distance of "x" mm from the new cut. The distance "x" is:

•35mm, when the tube must be inserted in a coupling with one Allen bolt.

•75mm, when the tube must be inserted in a coupling with two Allen bolts.