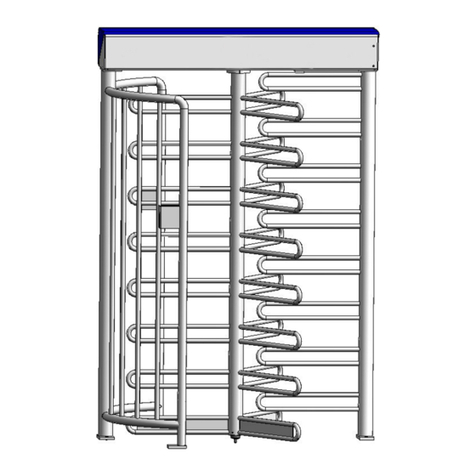

Magnetic Autocontrol MPT-333 User manual

Other Magnetic Autocontrol Turnstile manuals

Magnetic Autocontrol

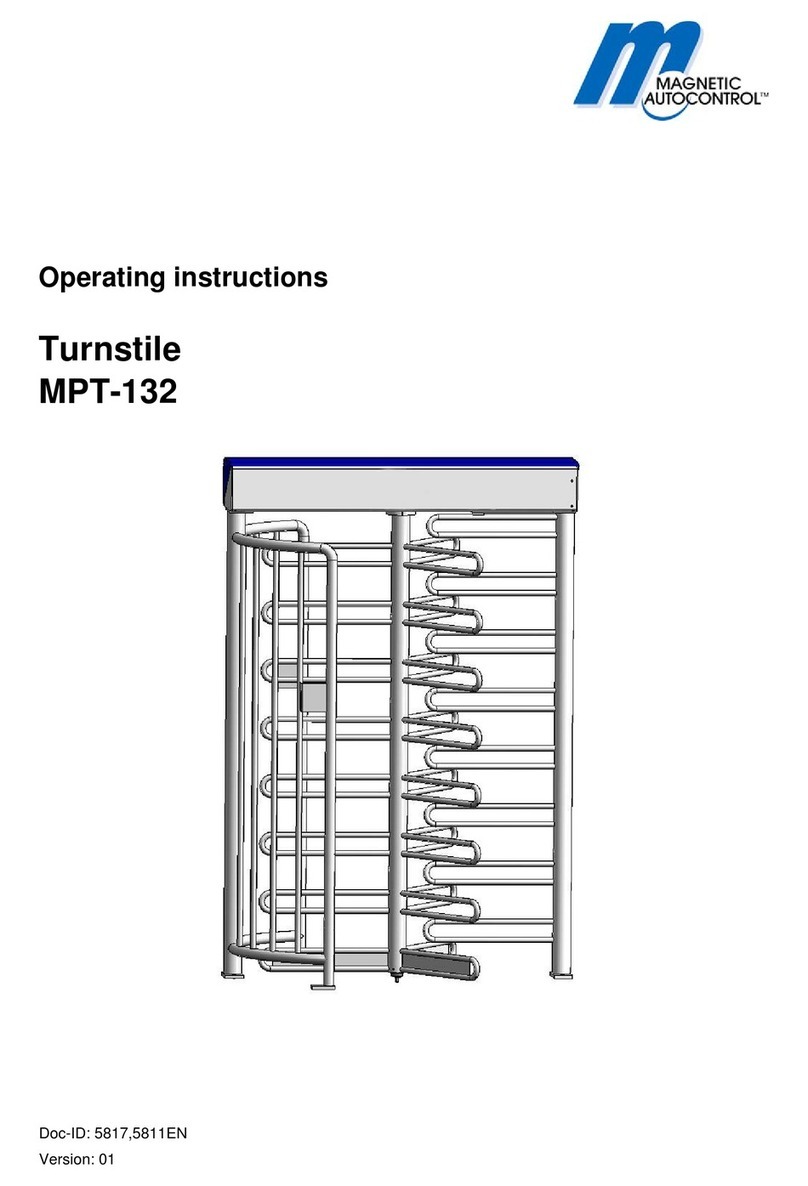

Magnetic Autocontrol MPT-132 User manual

Magnetic Autocontrol

Magnetic Autocontrol MPH 112 User manual

Magnetic Autocontrol

Magnetic Autocontrol MPT 33 User manual

Magnetic Autocontrol

Magnetic Autocontrol MPT-152 User manual

Magnetic Autocontrol

Magnetic Autocontrol MPT-132 User manual

Magnetic Autocontrol

Magnetic Autocontrol MPS-122 User manual

Popular Turnstile manuals by other brands

DSI

DSI DST-80 Service & installation manual

OZAK

OZAK VP-125 Assembly, Installation and Maintenance Handbook

Automatic Systems

Automatic Systems SMARTLANE SL 90X Technical manual

Alvarado

Alvarado MT Installation & maintenance instructions

JKDC SECURITY

JKDC SECURITY JKDC-100C user manual

Alvarado

Alvarado SU5000 quick guide