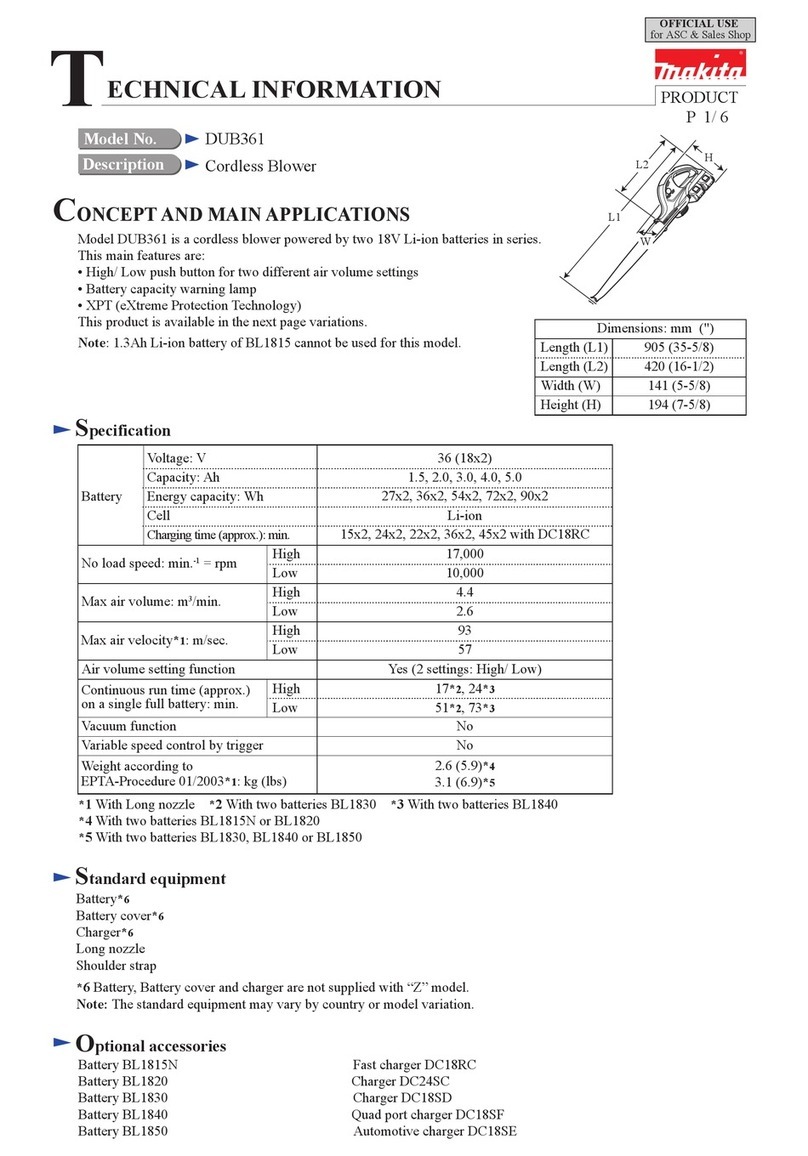

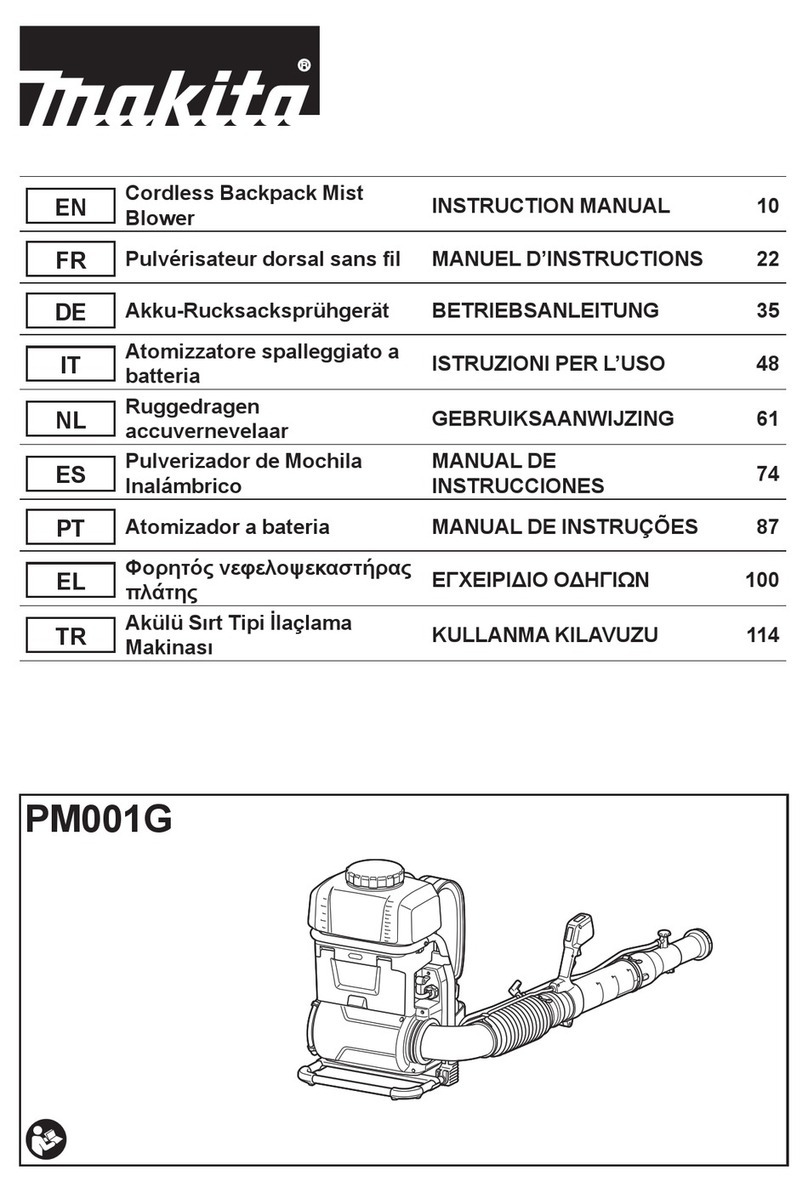

PRODUCT

P 1/26

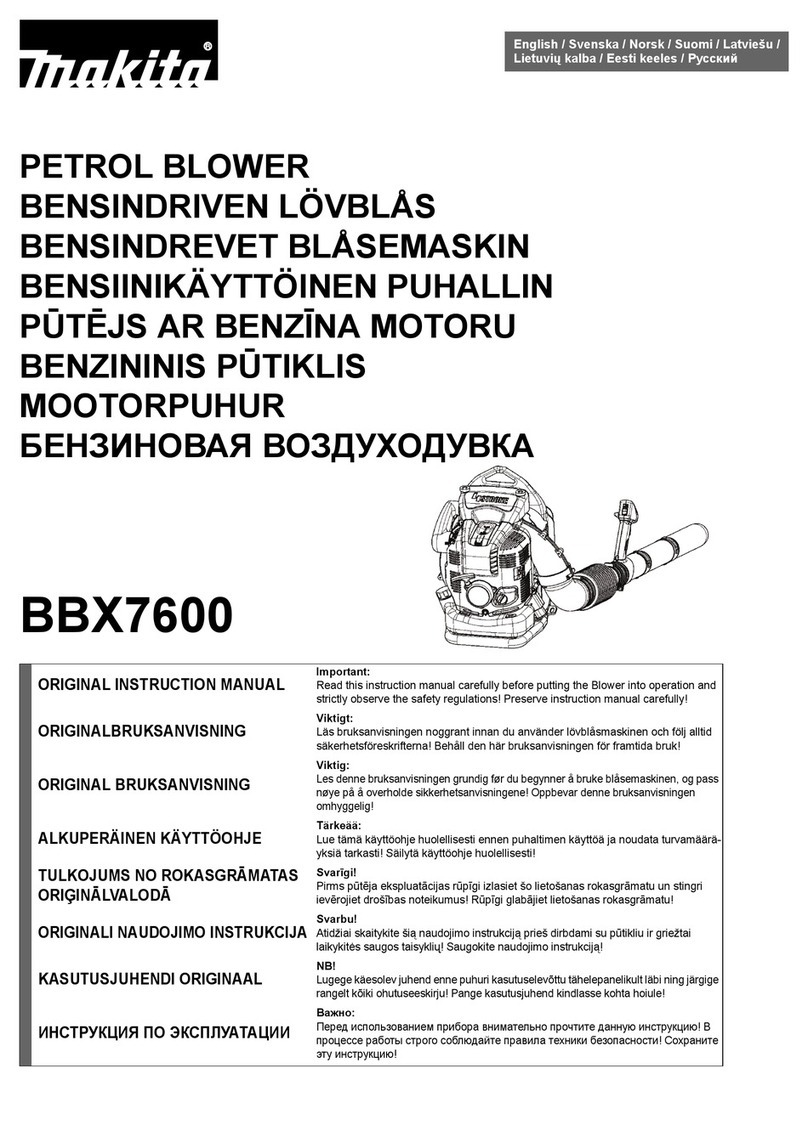

Models No. PM7650H

Description Petrol Mist Blower

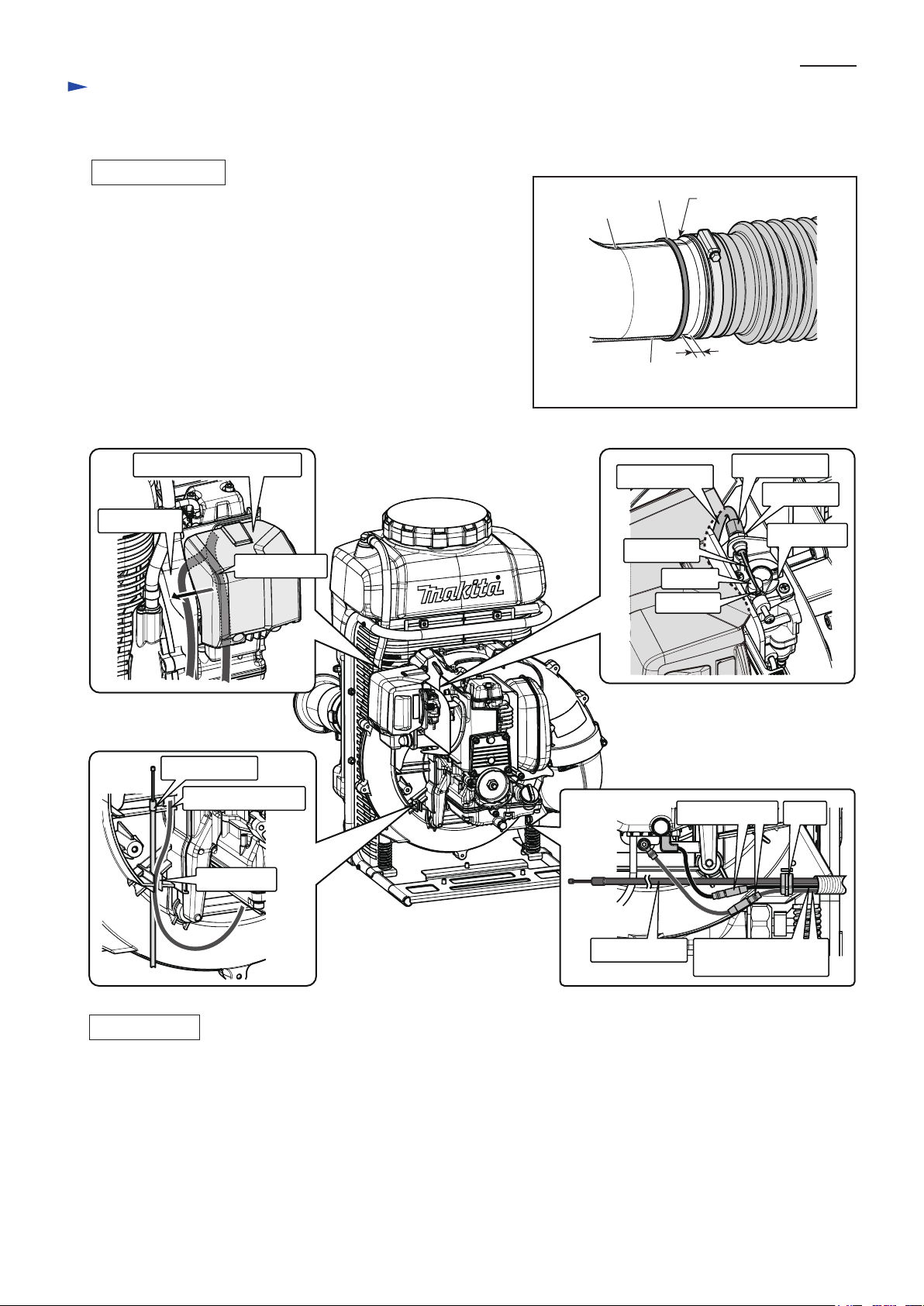

Model PM7650H is a Petrol mist blower equipped with

75.6cm³ 4-stroke engine in compliance with all major

exhaust emission regulations in the world, and features

16m max. horizontal spraying range and ergonomically

designed chemical tank.

This product is also available with E25 compatibility

for Brazil only as Model PM7650HG.

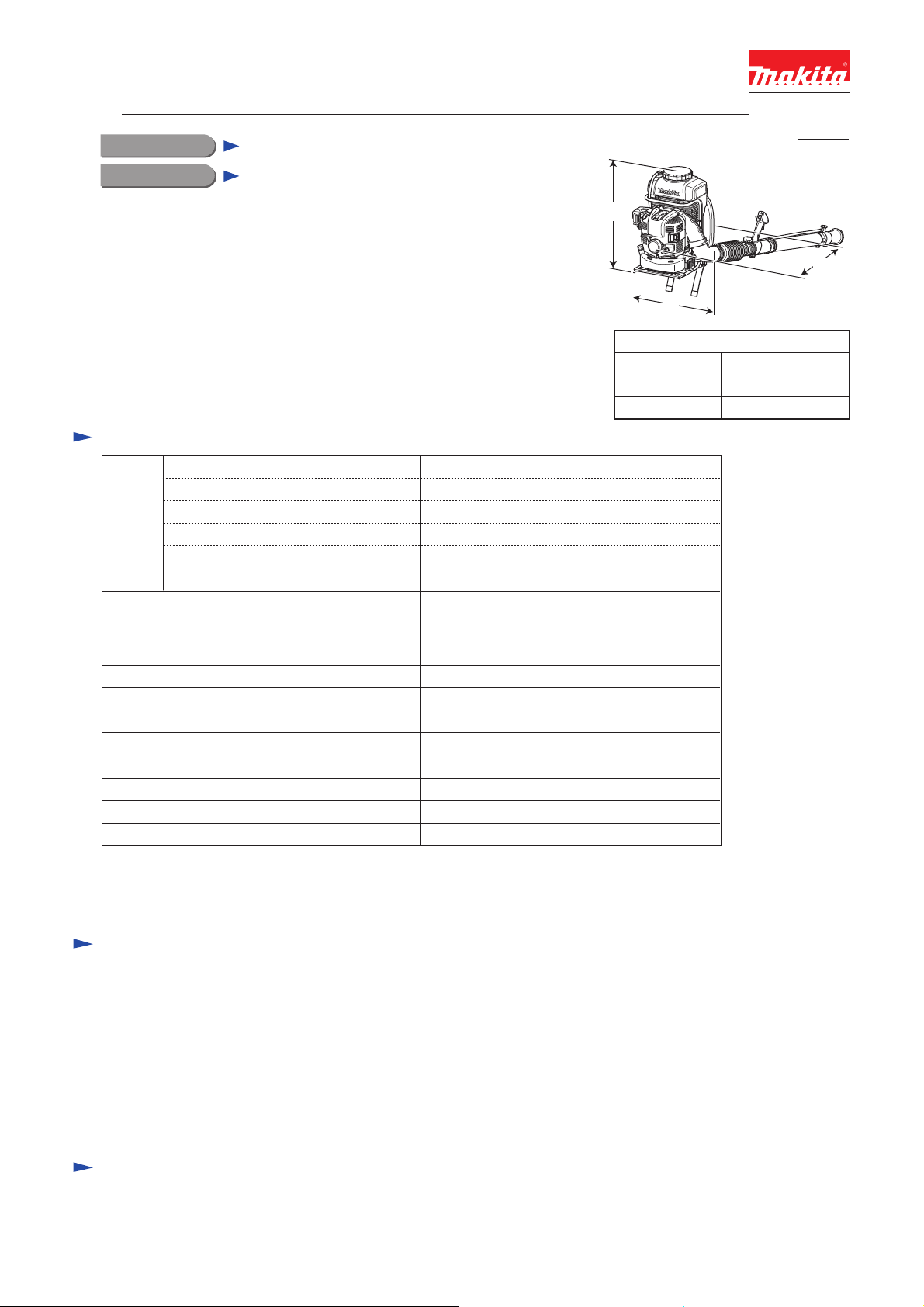

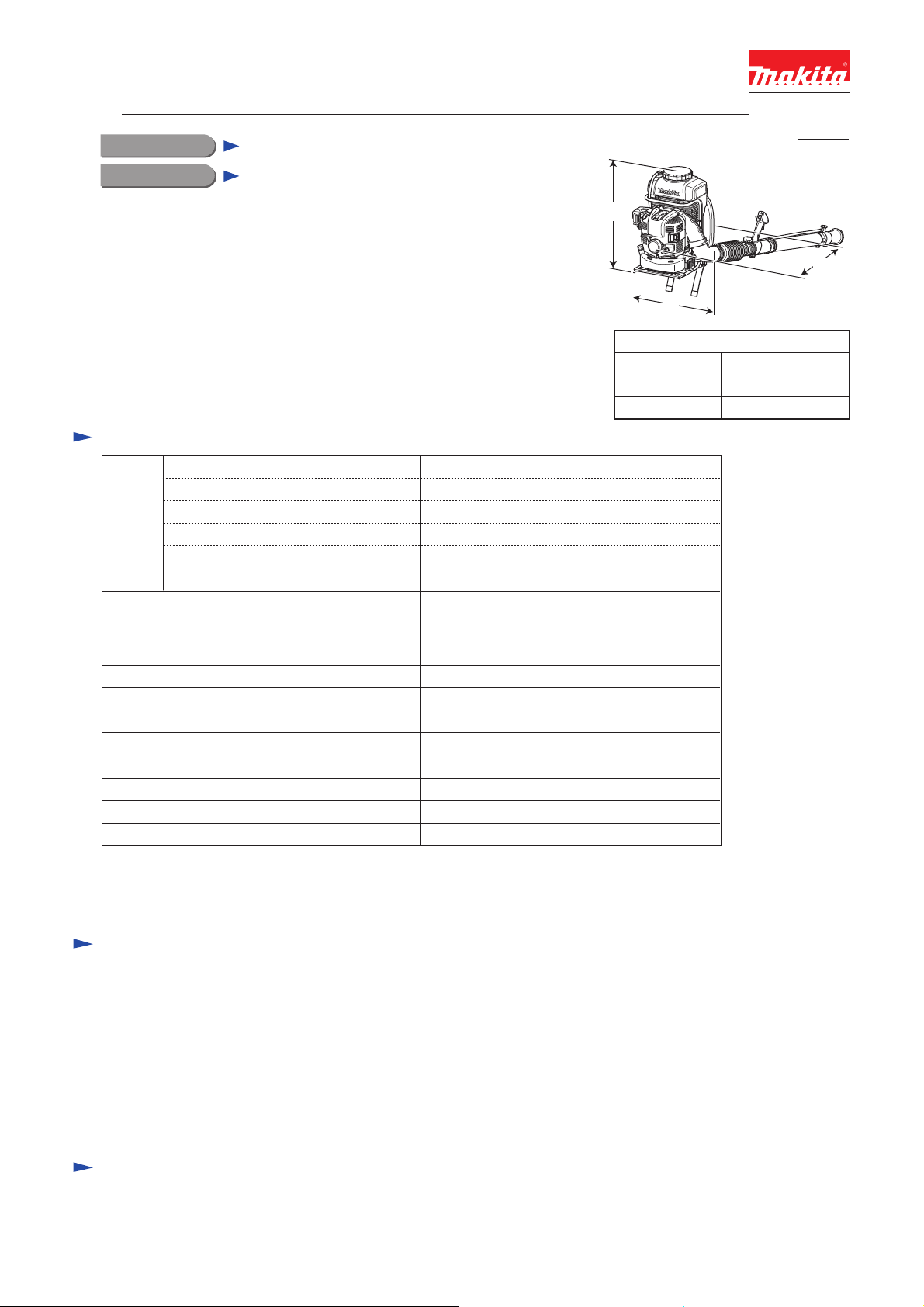

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

440 (17-1/4)

420 (16-1/2)

595 (23-1/2)

Diaphragm

75.6 (4.61)

2.7 (3.67) [at 7,000 min.ˉ¹]

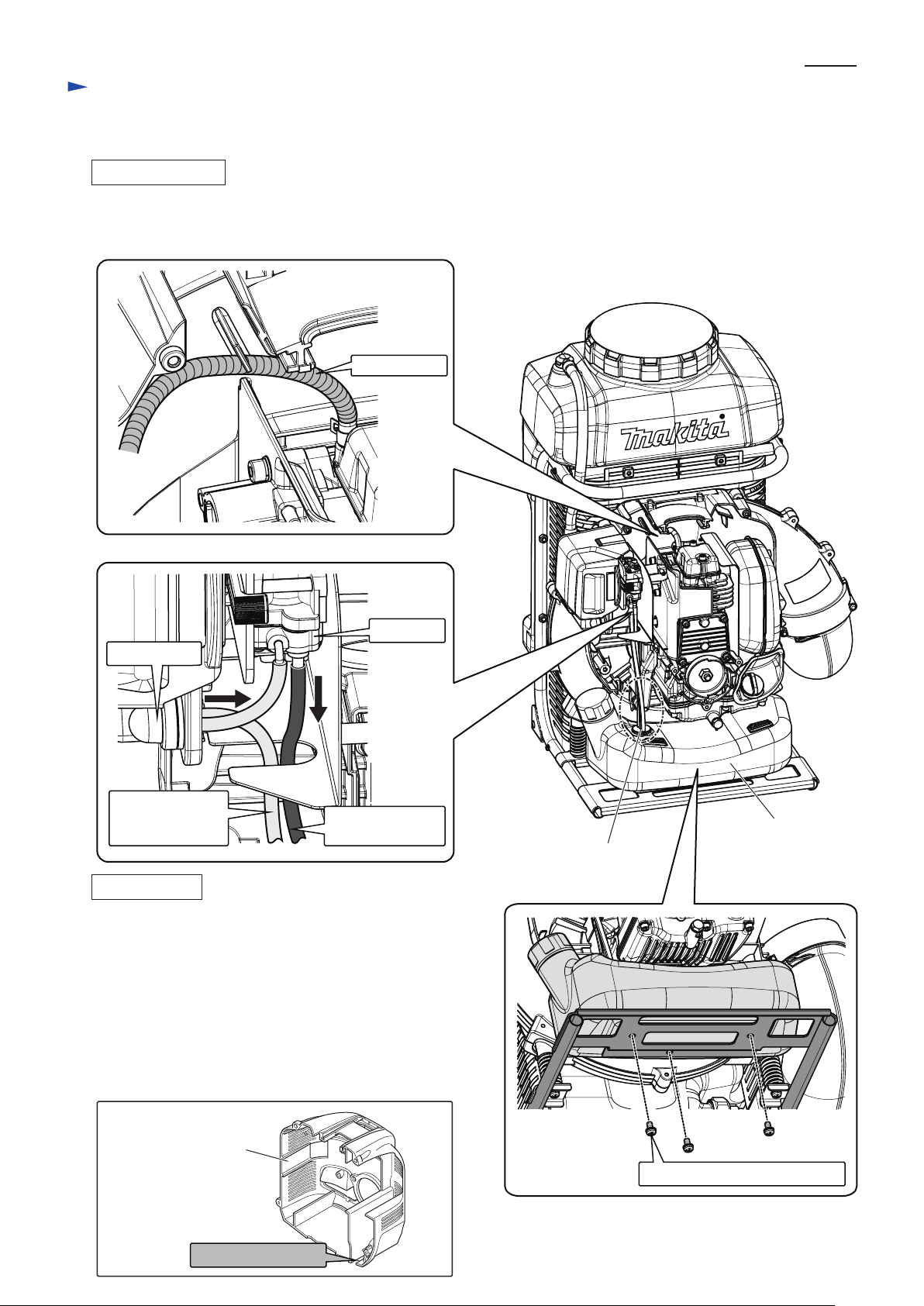

Carburetor

Yes

Max. engine speed: min.ˉ¹ = rpm

Idling speed: min.ˉ¹ = rpm

Starting system

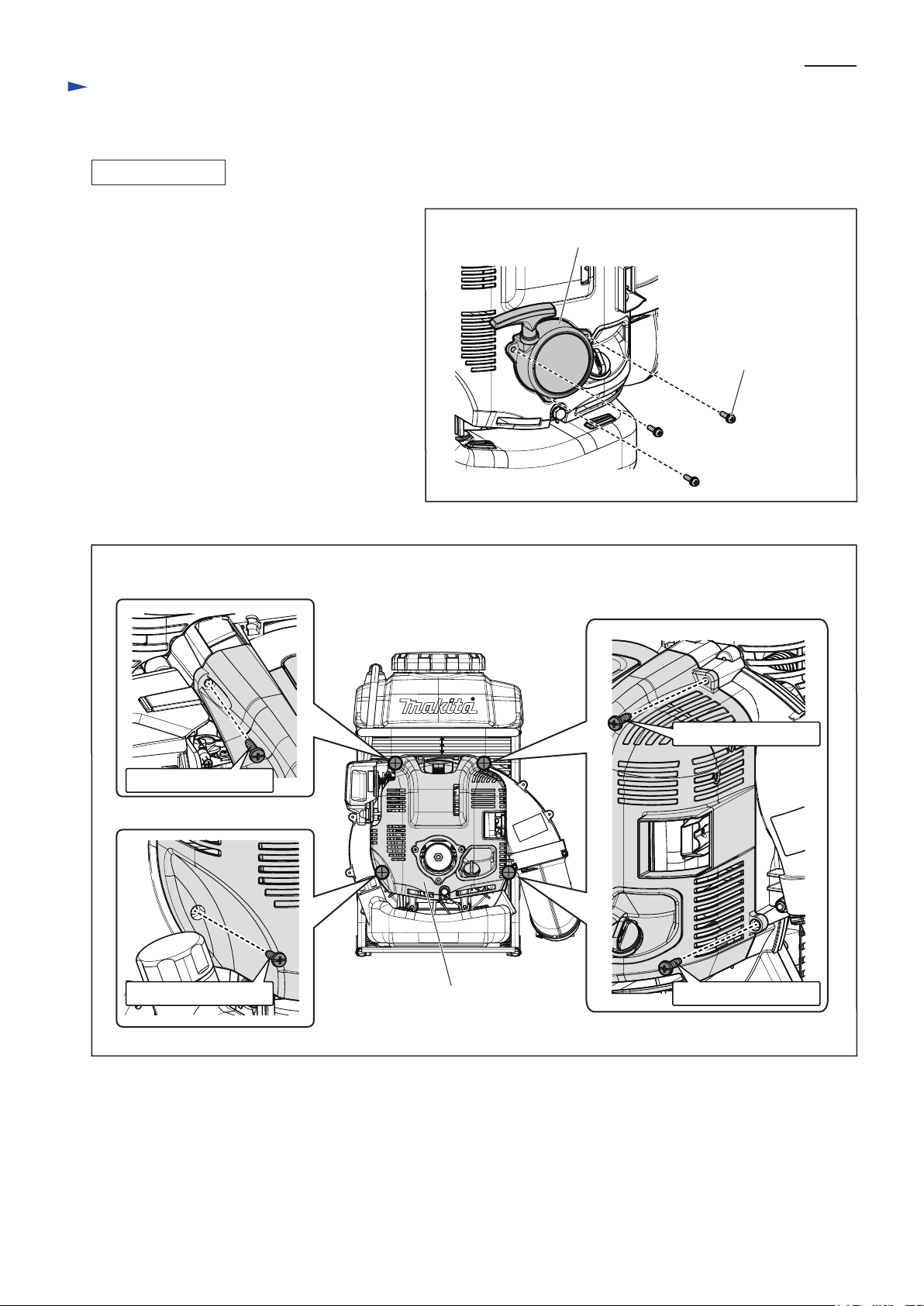

Engine

Displacement: cm³ (cu.in)

Max. output power: kW (PS)

4-strokeType

Max. spray range (horizontal): m (ft)

Dry weight*4: kg (lbs)

*1 Brazil: E25 gasoline

*2 This product is not in compliance with the regulations of San Dimas.

*3 with nozzle

*4 with Straight pipe 330

13.3 (29.3)

Recoil starter, with mechanical decompression

16.0 (52)

Max. air velocity: m/s

Max. air volume*3: m³/h

85

845

7,400

2,800

Fuel Straight gasoline*1

CONCEPT AND MAIN APPLICATIONS

Specification

Compliance with exhaust emission regulations*2;

CARB Tier 3, EPA Phase 2, EU Stage 2

SAE10W-30 oil

in Class SF or higher of API Classification

Engine oil

1.8 (61)Fuel tank capacity: L (US oz)

Chemical tank capacity: L (US oz) 15.0 (507)

TECHNICAL INFORMATION

H

W

L

Note: The standard equipment for the tool shown above may vary by country.

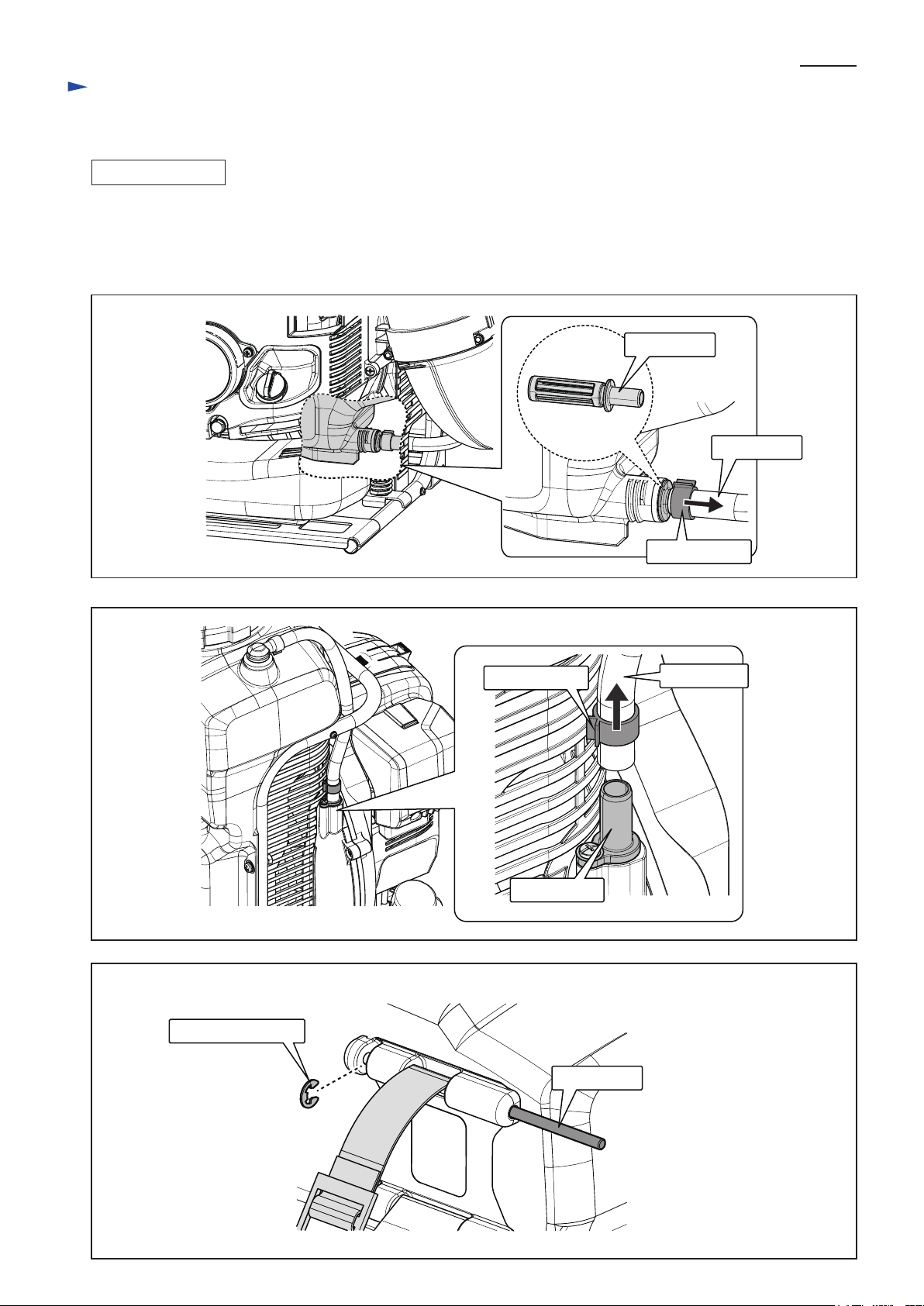

Oil bottle (containing 220ml of oil) ......... 1

Hand strap ............................................... 1

Box wrench ............................................. 1

Screwdriver ............................................. 1

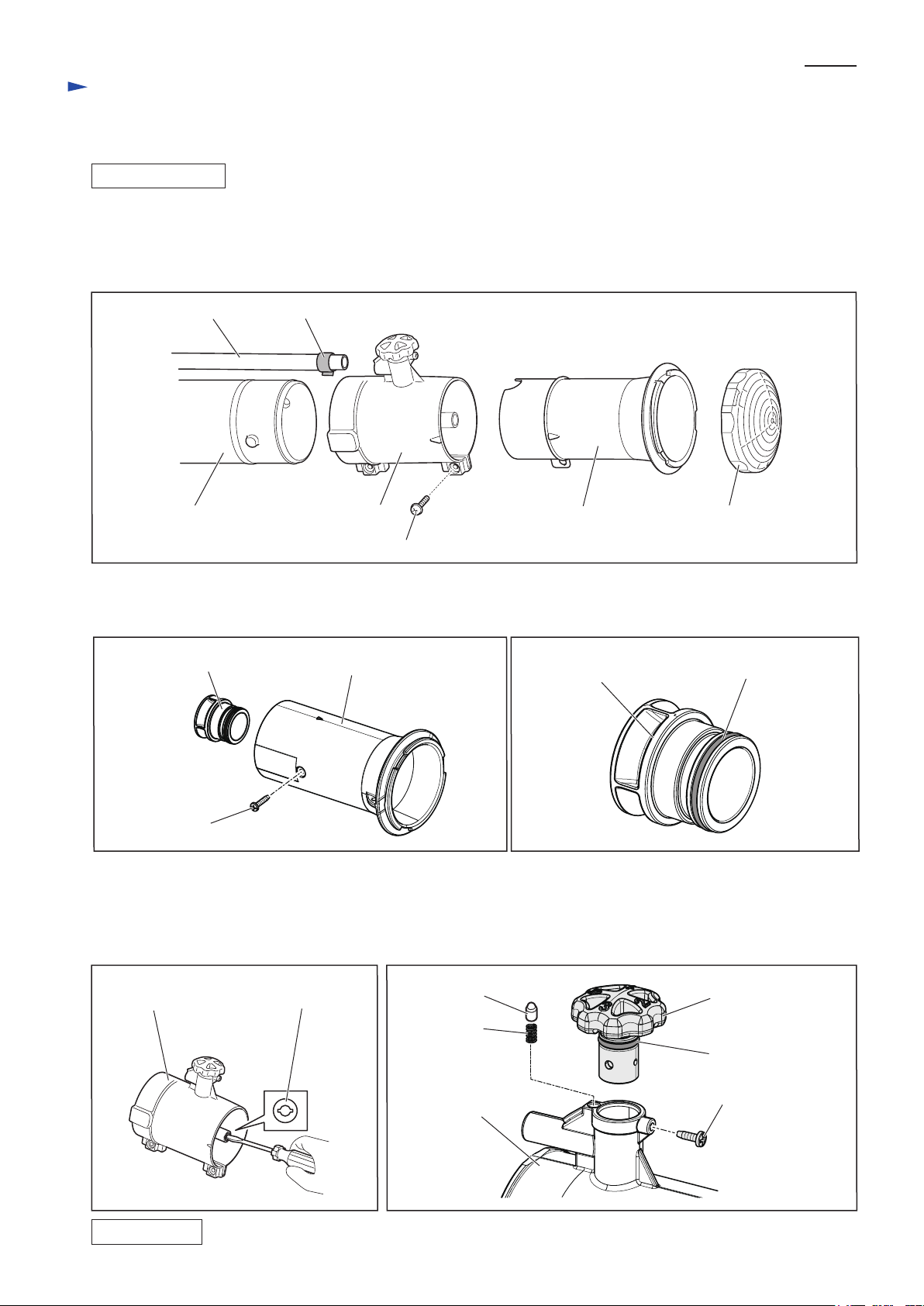

Diffusion cover

(Wide spray attachment) ......................... 1

Hose clamp 76 ......................................... 3

Hose clamp 100 ....................................... 1

Flexible pipe ............................................ 1

Straight pipe 330 ..................................... 1

Straight pipe 330

Straight pipe 630

Bent top pipe 630 (20º)

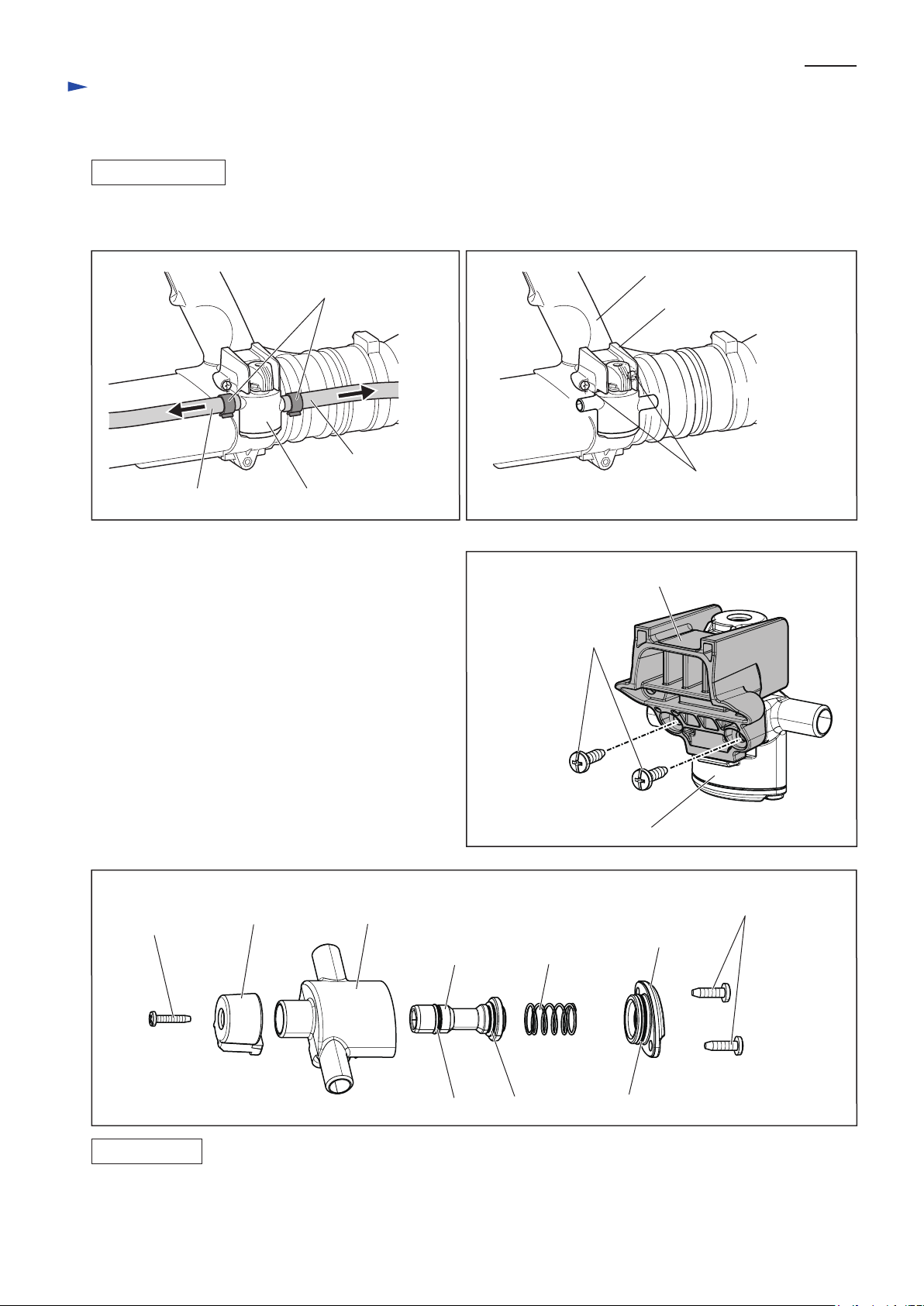

O ring set

Air cleaner element

Nozzle 0.7

Nozzle 0.8

Standard equipment

Optional accessories

Straight pipe 630 (for Brazil only)

Bent top pipe 630 (20º) (for Brazil only)

Tube 10-500 (for Brazil only)