5

4. Charge the Nickel Metal Hydride battery

cartridge when you do not use it for more than

six months.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

Installing or removing battery cartridge

Fig.1

• Always switch off the tool before insertion or

removal of the battery cartridge.

• To remove the battery cartridge, pull out the set

plate on the tool and grasp both sides of the

cartridge while withdrawing it from the tool.

• To insert the battery cartridge, align the tongue on

the battery cartridge with the groove in the housing

and slip it into place. Snap the set plate back into

place. Be sure to close the set plate fully before

using the tool to prevent the battery cartridge from

accidentally falling out of the tool.

• Do not use force when inserting the battery

cartridge. If the cartridge does not slide in easily, it

is not being inserted correctly.

Switch action

Fig.2

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the "OFF" position when

released.

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

Reversing switch action

Fig.3

CAUTION:

• Always check the direction of rotation before

operation.

• Use the reversing switch only after the tool comes

to a complete stop. Changing the direction of

rotation before the tool stops may damage the tool.

This tool has a reversing switch to change the direction of

rotation. Slide the reversing switch to the A side (appear

"F" marking) for clockwise rotation or to the B side

(appear "R" marking) for counterclockwise rotation.

Overload protector

For 6704D

The overload protector automatically cuts out to break

the circuit whenever heavy work is prolonged. Wait 20-30

seconds before resuming operation.

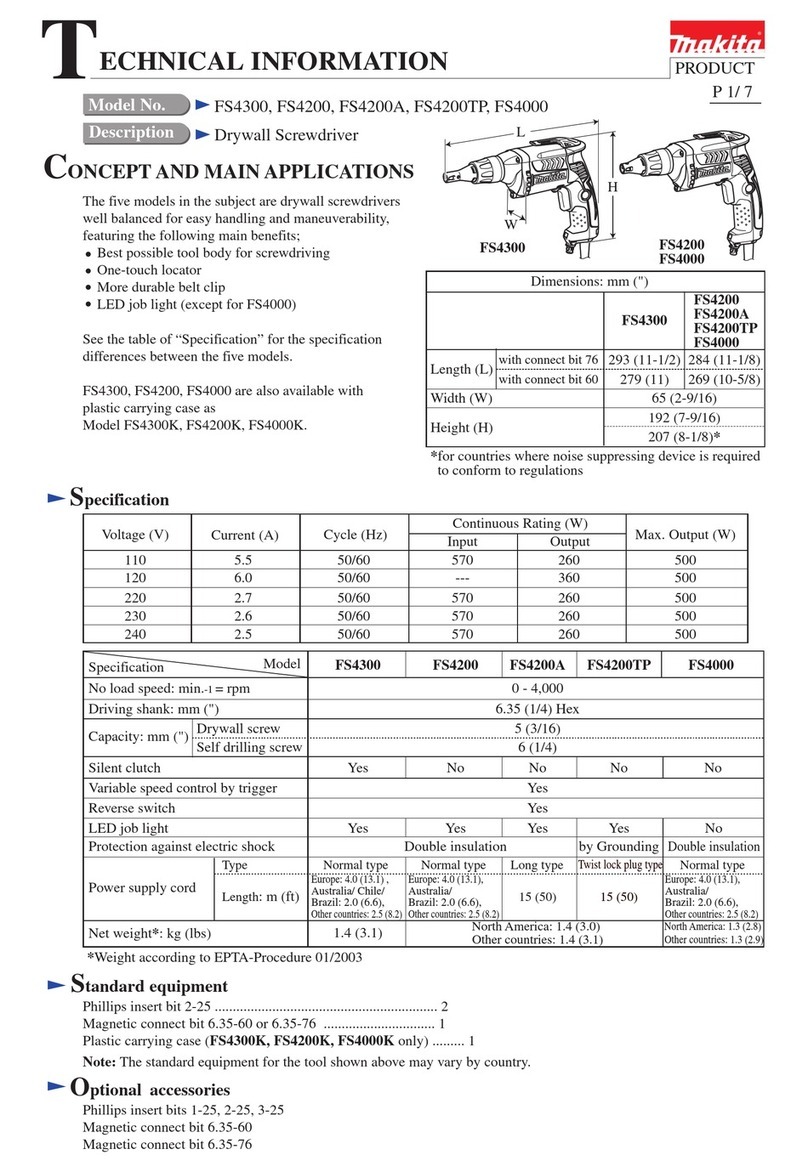

Adjusting the fastening torque

Fig.4

The fastening torque can be adjusted infinitely from

approx. 20 Kg•cm to 80 Kg•cm. To adjust it, loosen the

two screws and turn the adjusting ring. Then tighten the

screws to secure the adjusting ring. Refer to the table

below for relation between the numbers on the adjusting

ring and the fastening torque to be obtained.

1

2

3

4

5

Numberon adjusting ring Fastening torque tobe obtained

20 Kg cm

35 Kg cm

48 Kg cm

60 Kg cm

80 Kg cm

006402

Example

35 Kg• cm of fastening torque can be obtained when the

number 2 is aligned to the red mark.

NOTE:

• Always tighten the two screws to secure the

adjusting ring after adjusting the fastening torque.

• The fastening torque may differ depending upon

the kind of screws, the type of materials to be

fastened, etc. Before starting your job, always

perform a test operation to verify the adequate

fastening torque.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out

any work on the tool.

Installing or removing socket

For tool with square drive

Use 9.5 mm square drive socket with a hole for detent pin

which is available on the market ( Note: Use 6.35 mm

square drive socket when using the tool with 6.35 mm

drive.)

Fig.5

To install the socket, depress the detent pin on the

square drive with your finger and push the socket onto

the square drive until the detent pin is inserted into the

hole in the socket.

Fig.6

To remove the socket, depress the detent pin with a small

hand tool and pull off the socket.

For tool with round drive

Fig.7

Use a bit with Form C 6.3 shank which is available on the

market. The bit can be inserted directly into the round

drive and held in place.

To install the bit, push it firmly into the round drive. To

remove the bit, grasp it with a pair of pliers and pull it out