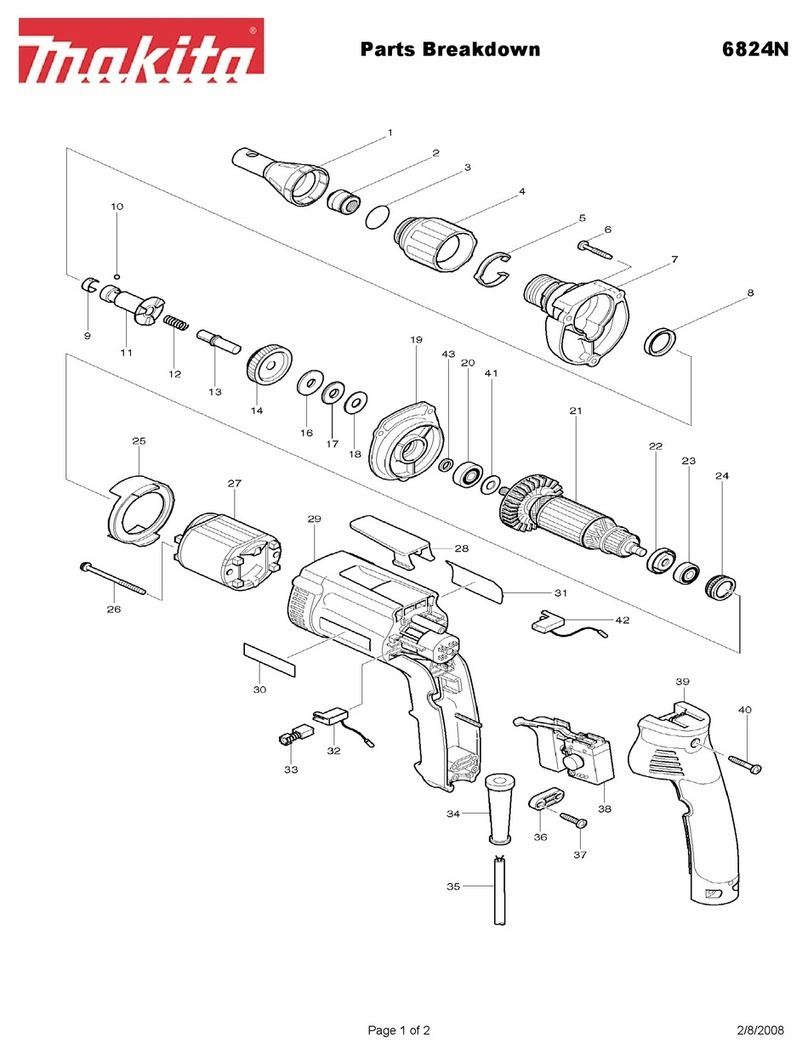

[4] DISASSEMBLY/ ASSEMBLY

[4]-1. Clutch portion (cont.)

Repair

P 4/ 7

Fig. 10

1) Remove three 4x30 Tapping screws. (Fig. 3)

While holding Gear housing cover complete not to separate from Motor housing, remove Gear housing TC from

Gear housing cover complete.

2) While holding Flat washer 12 and Compression spring 13 so as not to pop out, remove Ring spring 11 from Spindle

by enlarging the gap and lifting up the ring portion of Ring spring 11 from the groove of Spindle. (Fig. 10)

Flat washer 12, Compression spring 13, Sleeve 12 and two Steel balls 3.5 can be removed.

3) Tap Gear housing TC using plastic hammer from Gear housing cover complete matching side. (Fig. 4) Gear complete

17-39 can be removed from Gear housing TC.

4) Turn Clutch cover B complete clockwise to remove it from Gear housing TC. (Fig. 11)

Spindle 270D2, Compression spring 6, O ring 35 and Flat washer 36 can be removed.

5) Turn Ring 36 complete counterclockwise to remove it from Gear housing TC. (FIg. 11)

Compression spring 4 and Steel ball 4 can be removed.

Note: Steel ball 4 is easy to drop off. Be careful not to lose it.

6) Pick out two Pins 4. (Fig. 11) An assembled part illustrated in Fig. 6 can be removed.

7) Set the assembled part as illustrated in Fig. 7 using 1R045 with 1R346.

8) While keep setting the jaws of 1R045 to Clutch cam so as not to remove, turn the handle of 1R045 to pull down

Clutch cam. Then take out one of Steel ball 5.6 from insertion hole formed by the long groove of Spur gear 35

complete and the groove of Clutch cam. Use Slotted driver magnetized by 1R288. (Fig. 7)

9) Turn back the handle of 1R045 and reset 1R045 to Clutch cam. Then take out the remaining Steel balls 5.6 (2pcs.)

from the insertion hole.(Fig. 8)

Note: When it is difficult to remove the third Steel ball due to the misfit between the long groove of Spur gear 35

complete and the groove of Clutch cam, turn the gear teeth of Spur gear 35 complete to align their grooves.

10) Pull Spur gear 35 complete out of Sleeve, and the remaining components can be removed as illustrated in Fig. 9.

Note: Sixteen Steel balls 3.5 are easy to drop off. Be careful not to lose them.

DISASSEMBLING (FS2701)

ASSEMBLING

Fig. 12 Fig. 13

Fig. 11

1R291

Gap of

Ring spring 11

Take the disassembling step in reverse.

Note: After setting Flat washer 8 for Gear complete 17-39 in place as illustrated in Fig. 12, assemble them to Gear

housing TC.

Assemble Urethane washer 8, two Washers 821 and Thrust needle cage 821 to Spur gear 35 complete properly

as illustrated in Fig. 6.

When assembling Ring 36 complete for FS2701 to Gear housing TC, hold Steel ball 4 on Gear housing TC using

thin plate to prevent Steel ball 4 from rolling along the turns of Ring spring 36 complete. (Fig. 13)

Ring portion of

Ring spring 11

Flat washer 12 and Compression

spring 13 under Ring spring 11

Sleeve

Pin 4

(2pcs.)

Flat

washer 36

Compression

spring 6

Compression

spring 4

O ring 35 Clutch cover

B complete

Spindle 270D2

Steel ball 3.5 (2pcs.)

Steel ball 4

Gear

housing

TC

Ring 36

complete

Gear complete 17-39

Flat washer 8 thin plate

Steel ball 4

on Gear

housing TC

Ring 36 complete

for FS2701

Ball bearing

606ZZ