Makita 6831D User manual

Other Makita Power Screwdriver manuals

Makita

Makita DFT060T User manual

Makita

Makita DFL650F User manual

Makita

Makita 6842 User manual

Makita

Makita 6820V User manual

Makita

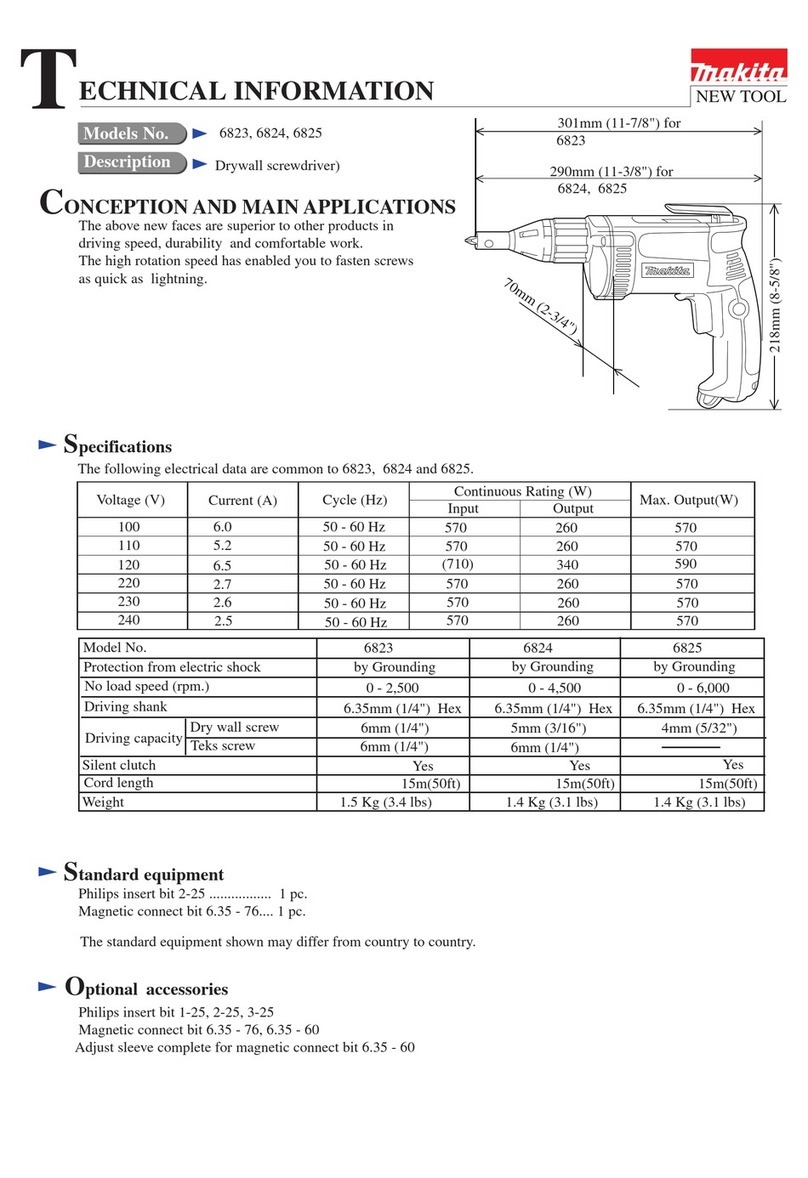

Makita 6823 Manual

Makita

Makita BFT044F User manual

Makita

Makita DFS250RAJ User manual

Makita

Makita DFR540 User manual

Makita

Makita BDA350 User manual

Makita

Makita 6720D User manual

Makita

Makita DFT041F User manual

Makita

Makita BFR540 User manual

Makita

Makita 68OODBV User manual

Makita

Makita DFR452 User manual

Makita

Makita 6796D User manual

Makita

Makita 6821 User manual

Makita

Makita DDA450 User manual

Makita

Makita DFT024F User manual

Makita

Makita 6842 User manual

Makita

Makita AR410HR User manual

Popular Power Screwdriver manuals by other brands

Festool

Festool TI 15 operating manual

Matatakitoyo Torque Tools

Matatakitoyo Torque Tools MTD Operation manual

Skil

Skil 2346 Operating/safety instructions

DeWalt

DeWalt XR LI-ION DCD931 user manual

Festool

Festool DWC 18-2500 operating manual

EINHELL

EINHELL TE-CD 12/1 Li Series Original operating instructions