8ENGLISH

8. Wear hearing protection to protect your ears

against exhaust noise and head protection.

Also wear light but not loose clothing. Sleeves

should be buttoned or rolled up. No necktie

should be worn.

Operating hazards

1. Hold the tool correctly: be ready to counteract

normal or sudden movements such as recoil.

2. Maintain a balanced body position and secure

footing.

3. Appropriate safety glasses shall be used and

appropriate gloves and protective clothing are

recommended.

4. Appropriate hearing protection shall be worn.

5. Use the correct energy supply as directed in

the instruction manual.

6. Do not use the tool on moving platforms or

back of trucks. Sudden movement of the platform

may lose control of the tool and cause injury.

7.

Always assume that the tool contains fasteners.

8. Do not rush the job or force the tool. Handle

the tool carefully.

9. Watch your footing and maintain your balance

with the tool. Make sure there is no one below

when working in high locations, and secure the air

hose to prevent danger if there is sudden jerking

or catching.

10. On rooftops and other high locations, drive

fasteners as you move forward. It is easy to lose

your footing if you drive fasteners while inching

backward. When driving fasteners against perpen-

dicular surface, work from the top to the bottom.

You can perform driving operations with less

fatigue by doing so.

11. A fastener will be bent or the tool can become

jammed if you mistakenly drive fastener on

top of another fastener or strike a knot in the

wood. The fastener may be thrown and hit

someone, or the tool itself can react danger-

ously. Place the fasteners with care.

12. Do not leave the loaded tool or the air com-

pressor under pressure for a long time out in

the sun. Be sure that dust, sand, chips and

foreign matter will not enter the tool in the

place where you leave it setting.

13. Never attempt to drive fasteners from both the

inside and outside at the same time. Fasteners

may rip through and/or y o, presenting a grave

danger.

Repetitive motions hazards

1.

When using a tool for long periods, the operator

may experience discomfort in the hands, arms,

shoulders, neck, or other parts of the body.

2. While using a tool, the operator shall adopt

a suitable but ergonomic posture. Maintain

secure footing and avoid awkward or o-bal-

anced postures.

3. If the operator experiences symptoms such

as persistent or recurring discomfort, pain,

throbbing, aching, tingling, numbness, burn-

ing sensation, or stiness, do not ignore these

warning signs. The operator should consult a

qualied health professional regarding overall

activities.

4. The continuous use of the tool may cause

repetitive strain injury due to recoil produced

by the tool.

5. To avoid repetitive strain injury, the operator

should not overreach or use excessive force.

Additionally, the operator should take a rest

when feeling fatigue.

6.

Conduct a risk assessment regarding repetitive

motion hazards. It should focus on muscu-

lar-skeletal disorders and be preferentially based

on the assumption that decreasing fatigue during

work is eective in reducing disorders.

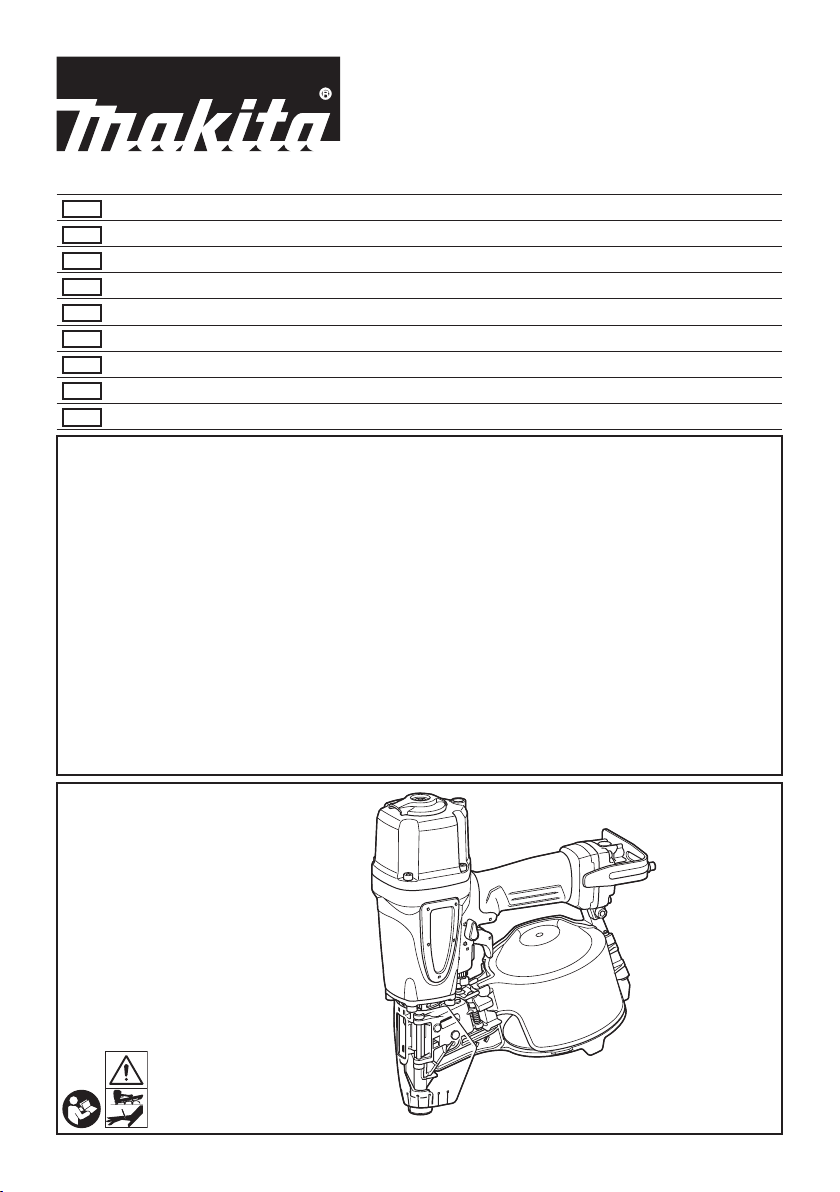

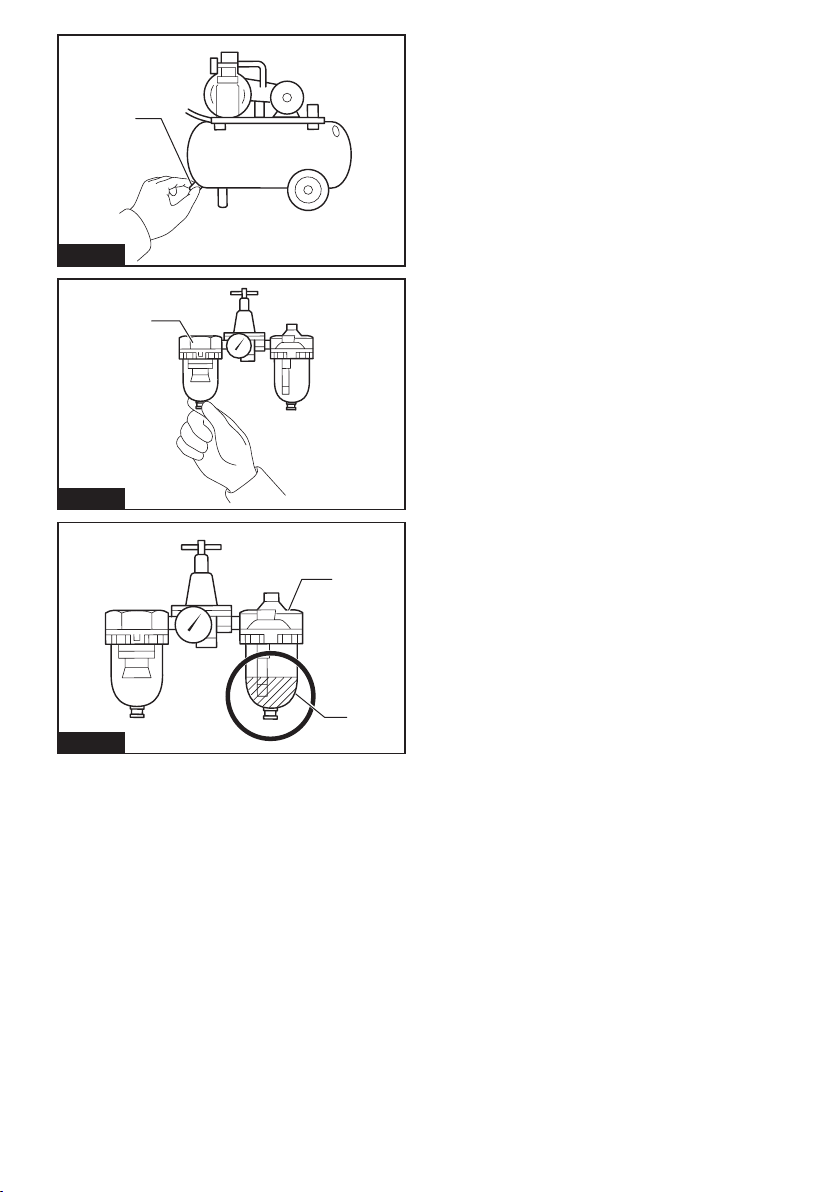

Accessory and consumable hazards

1. Disconnect the energy supply to the tool, such

as air or gas or battery as applicable, before

changing/replacing accessories such as work-

piece contact, or making any adjustments.

2. Use only the sizes and types of accessories

that are provided by the manufacturer.

3. Use only lubricants recommended in this

manual.

Workplace hazards

1. Slips, trips and falls are major causes of work-

place injury. Be aware of slippery surfaces

caused by use of the tool and also of trip haz-

ards caused by the air line hose.

2. Proceed with additional care in unfamiliar

surroundings. Hidden hazards may exist, such

as electricity or other utility lines.

3. This tool is not intended for use in potentially

explosive atmospheres and is not insulated

from coming into contact with electric power.

4. Make sure there are no electrical cables, gas

pipes etc. that could cause a hazard if dam-

aged by use of the tool.

5. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

6. There may be local regulations concerning

noise which must be complied with by keeping

noise levels within prescribed limits. In certain

cases, shutters should be used to contain

noise.

Dust and exhaust hazards

1. Always check your surroundings. The air

exhausted from the tool may blow dust or

objects and hit operator and/or bystanders.

2. Direct the exhaust so as to minimize distur-

bance of dust in a dust lled environment.

3. If dust or objects are emitted in the work area,

reduce the emission as much as possible to

reduce the health hazards and risk of injury.

Noise hazards

1. Unprotected exposure to high noise levels can

cause permanent, disabling, hearing loss and

other problems such as tinnitus (ringing, buzz-

ing, whistling or humming in the ears).

2. Conduct a risk assessment regarding noise

hazards in the work area and implement appro-

priate controls for these hazards.

3. Appropriate controls to reduce the risk may

include actions such as damping materials to

prevent workpieces from "ringing".

4. Use appropriate hearing protection.