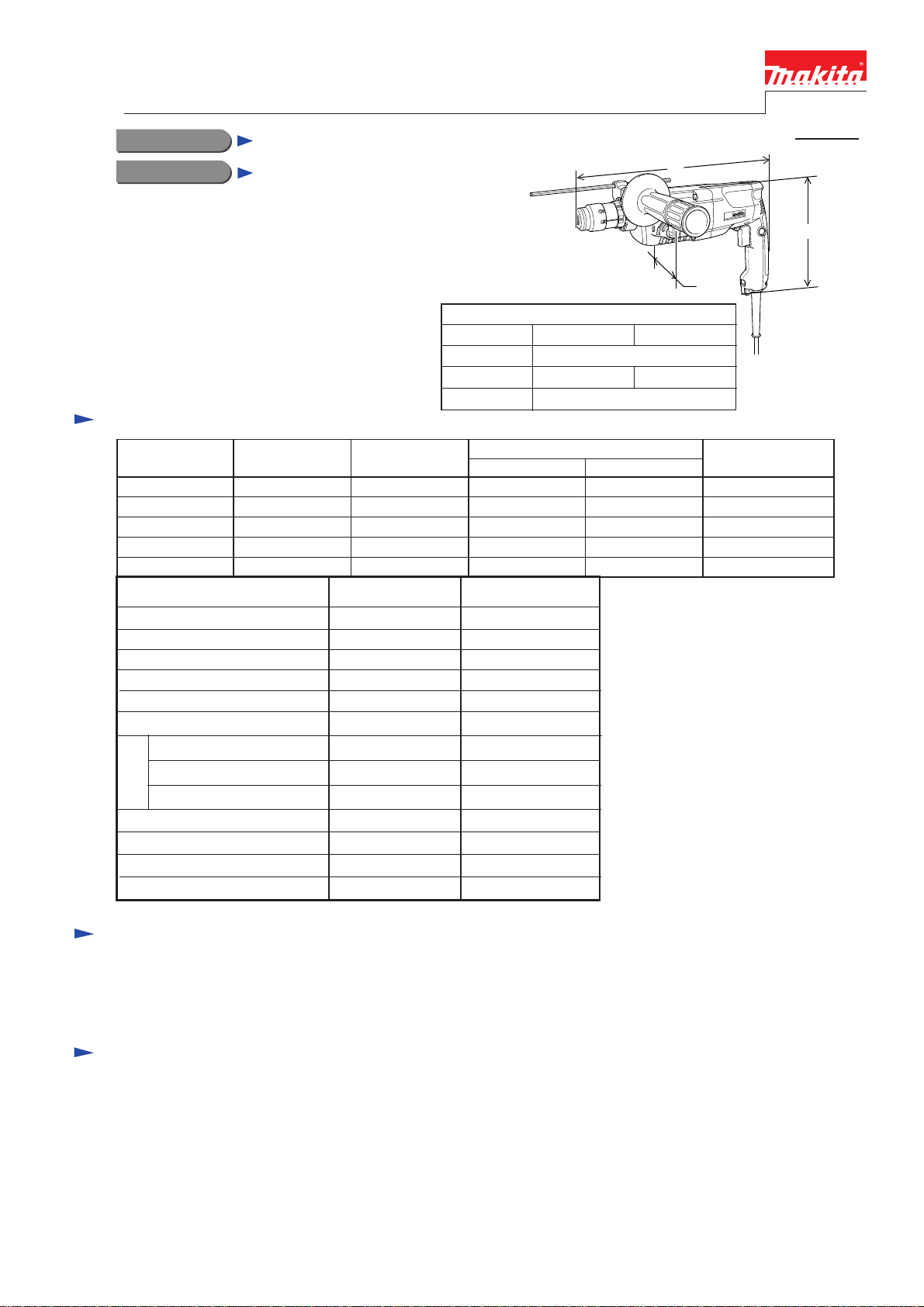

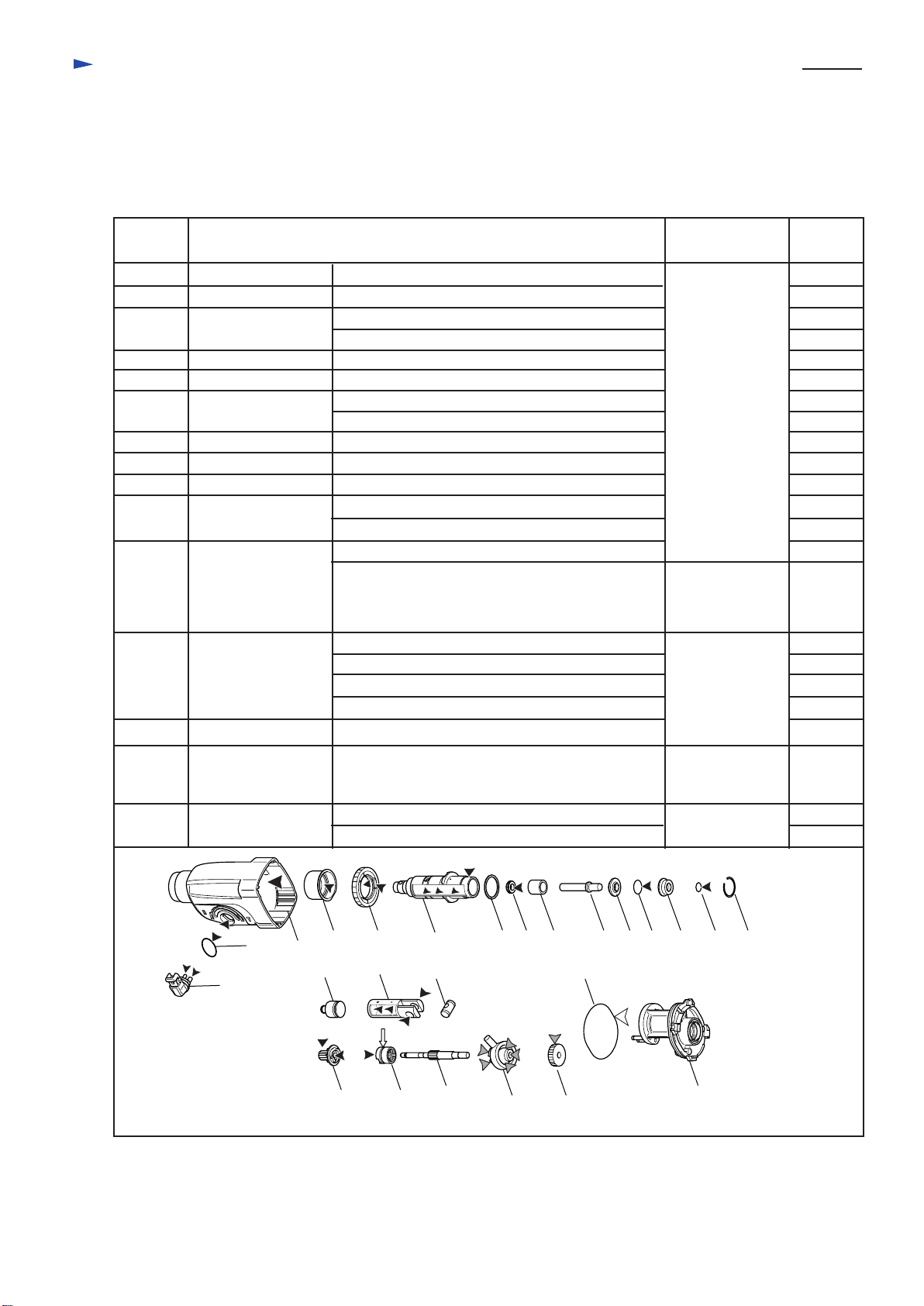

Makita HR2450FT Manual

Other Makita Rotary Hammer manuals

Makita

Makita BHR240 Manual

Makita

Makita HR005GZ04 User manual

Makita

Makita DHR183 User manual

Makita

Makita DHR165ZJ User manual

Makita

Makita HR5210C User manual

Makita

Makita HR2800 User manual

Makita

Makita BHR180 User manual

Makita

Makita HR2450/T User manual

Makita

Makita HR5001C User manual

Makita

Makita HR140DZ User manual

Makita

Makita HR166D User manual

Makita

Makita HR166D User manual

Makita

Makita HR2420 Quick start guide

Makita

Makita HK0500 User manual

Makita

Makita HR4030C Manual

Makita

Makita GRH06 User manual

Makita

Makita HR4002 User manual

Makita

Makita HR2510 User manual

Makita

Makita HR2470T User manual

Makita

Makita HR3520 User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

BTI

BTI Profiline BTI-BH 24 VE operating instructions