Makita 2414EN Manual

Other Makita Saw manuals

Makita

Makita BLS820SF Manual

Makita

Makita JR3051T User manual

Makita

Makita PB002GZ User manual

Makita

Makita LS0714FL User manual

Makita

Makita LS1400 User manual

Makita

Makita 5606B User manual

Makita

Makita DLS714 User manual

Makita

Makita LS1216 User manual

Makita

Makita LS1017 User manual

Makita

Makita SP6000 User manual

Makita

Makita 5621RD User manual

Makita

Makita DPB181RFE User manual

Makita

Makita BLS820 User manual

Makita

Makita MLT100N User manual

Makita

Makita XWL01 User manual

Makita

Makita DLS713NZ User manual

Makita

Makita LS1040 User manual

Makita

Makita 5143R User manual

Makita

Makita DPB180 User manual

Makita

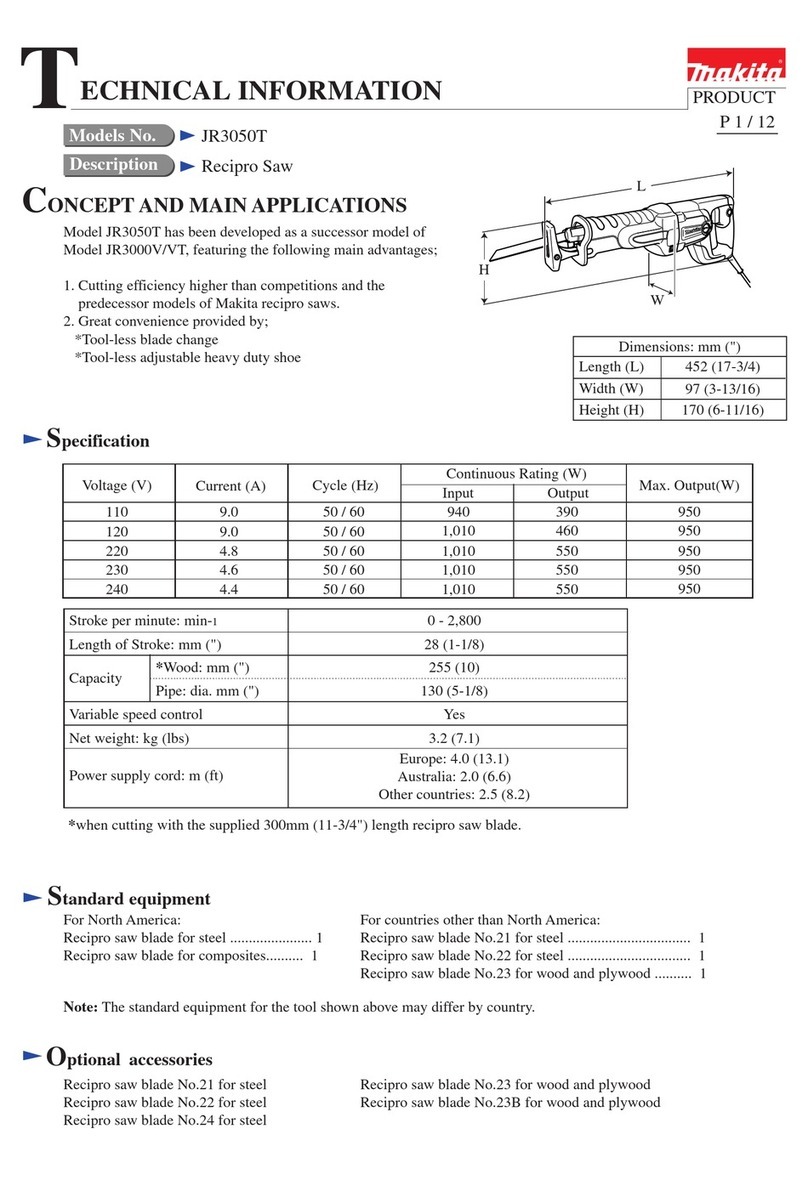

Makita JR3050T Manual