3

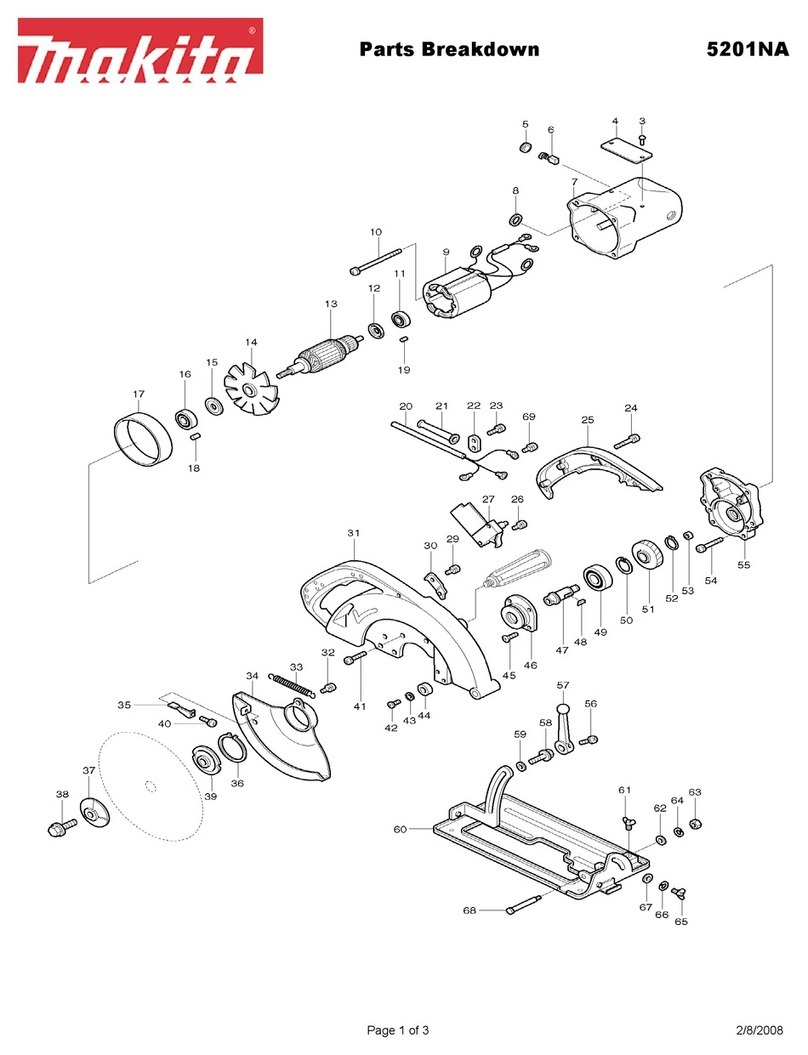

17. USE RECOMMENDED ACCESSORIES.

Consult the owner's manual for recommended

accessories. The use of improper accessories

may cause risk of injury to persons.

18. NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool

is unintentionally contacted.

19. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function - check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade

or cutter against the direction of rotation of the

blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Do not leave tool until it

comes to a complete stop.

22. REPLACEMENT PARTS. When servicing, use

only identical replacement parts.

23. POLARIZED PLUGS. To reduce the risk of

electric shock, this appliance has a polarized

plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet.

Do not change the plug in any way.

VOLTAGE WARNING: Before connecting the tool to a

power source (receptacle, outlet, etc.) be sure the

voltage supplied is the same as that specified on the

nameplate of the tool. A power source with voltage

greater than that specified for the tool can result in

SERIOUS INJURY to the user- as well as damage to

the appliance. If in doubt, DO NOT PLUG IN THE

APPLIANCE. Using a power source with voltage less

than the nameplate rating is harmful to the motor.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 1

shows the correct size to use depending on cord

length and nameplate ampere rating. If in doubt, use

the next heavier gage. The smaller the gage number,

the heavier the cord.

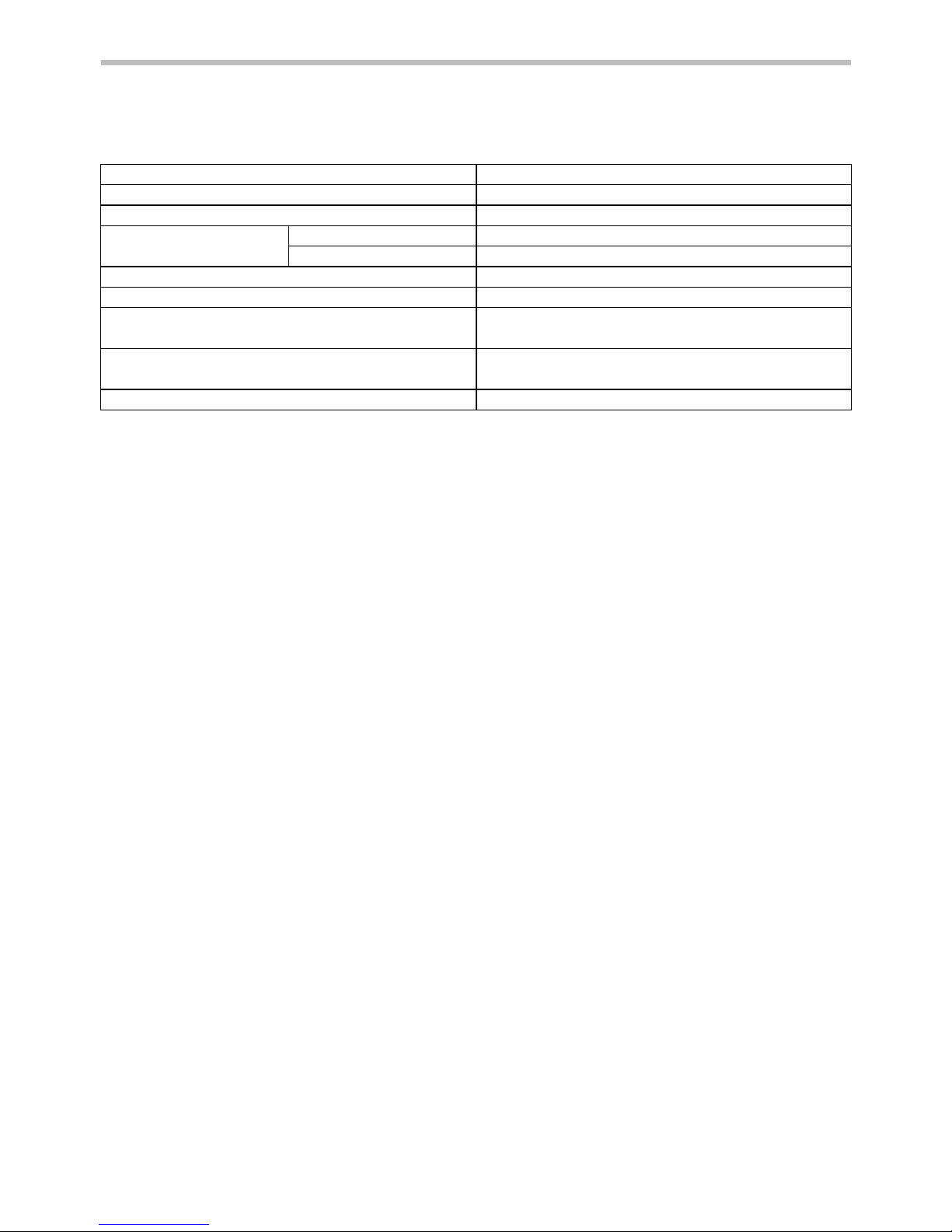

Table 1: Minimum gage for cord

Ampere Rating Volts Total length of cord in feet

120 V 25 ft. 50 ft. 100 ft. 150 ft.

More Than Not More Than AWG

0 6 18 16 16 14

18 16 14 12610

10 12 16 16 14 12

12 16 14 12 Not Recommended

000173

USB059-1

ADDITIONAL SAFETY RULES

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to table saw safety rules. If you use this tool unsafely

or incorrectly, you can suffer serious personal

injury.

1. Wear eye protection.

2. Do not use the tool in presence of flammable

liquids or gases.

3. NEVER use the tool with an abrasive cut-off

wheel installed.

4. Check the blade carefully for cracks or

damage before operation. Replace cracked or

damaged blade immediately.

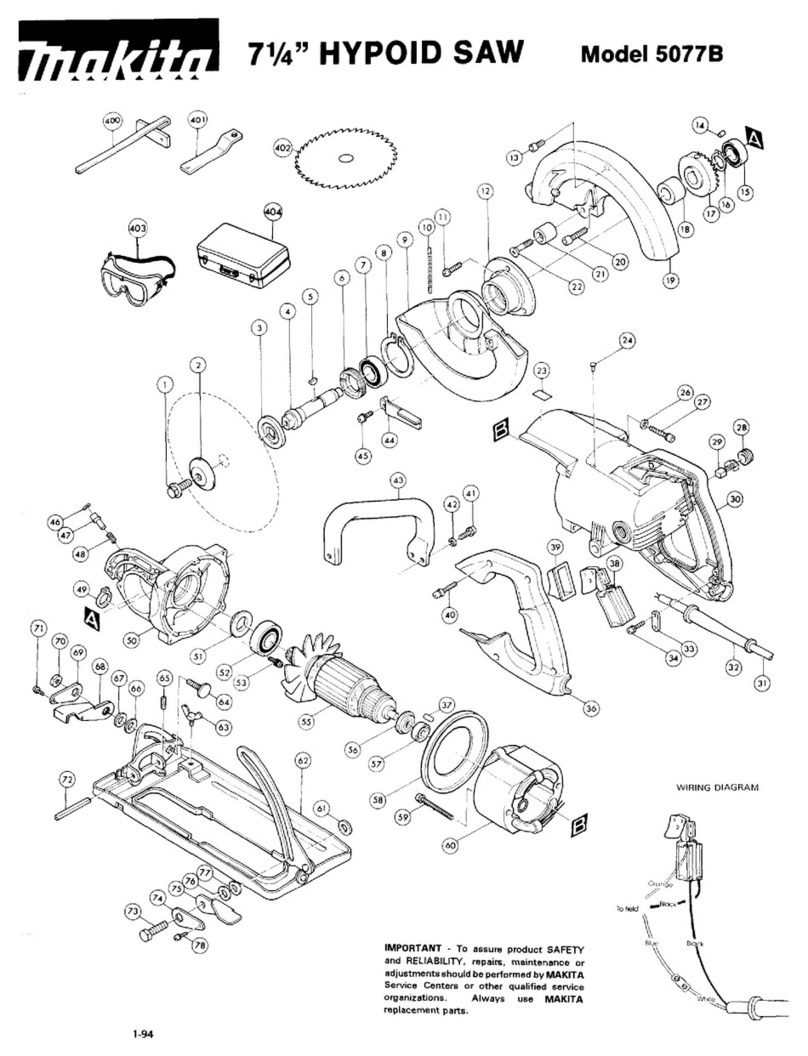

5. Clean the spindle, flanges (especially the

installing surface) and hex nut before

installing the blade. Poor installation may

cause vibration/wobbling or slippage of the

blade.

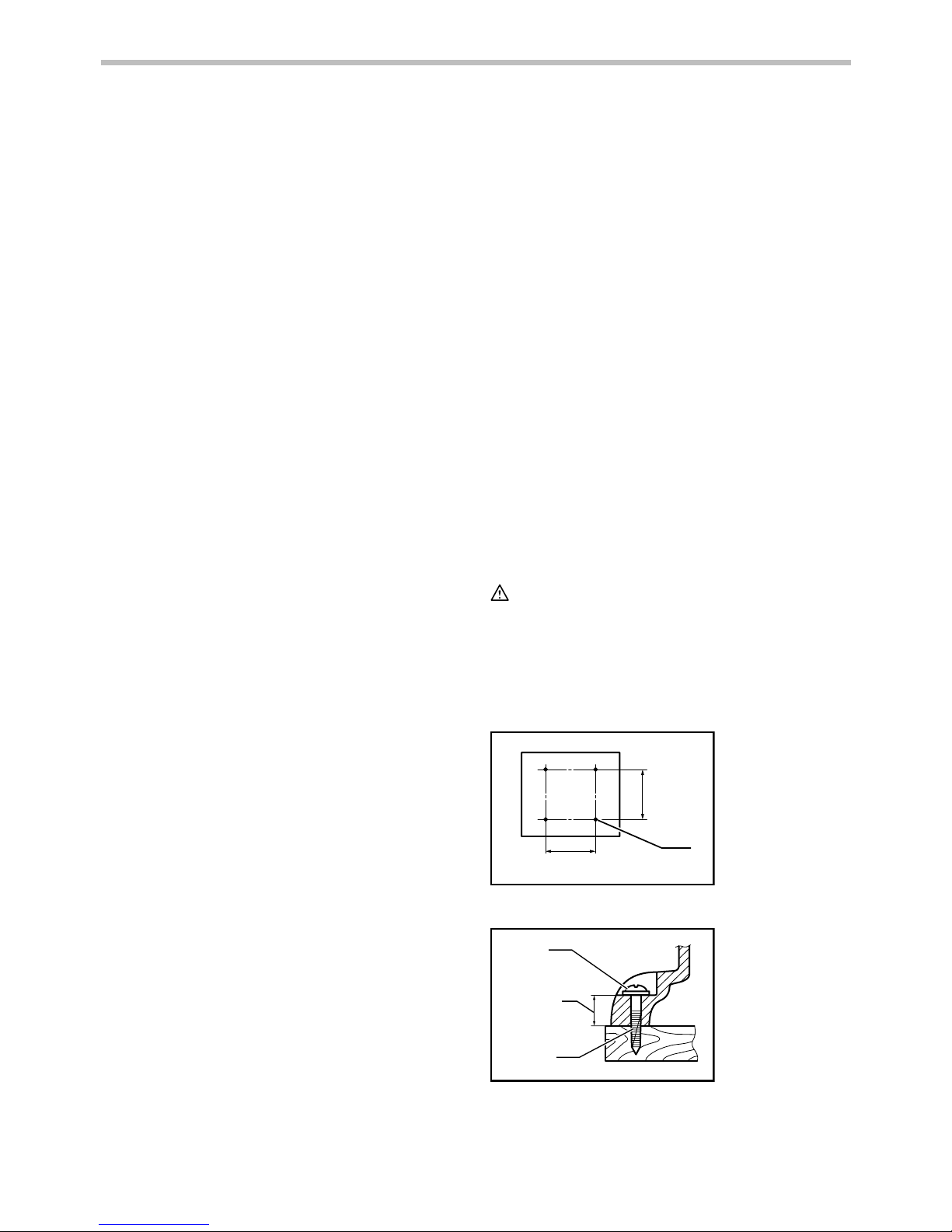

6. Use saw-blade guard and spreader for every

operation for which it can be used, including

all through sawing operations. Always

assemble and install the blade guard following

the step by step instructions out-lined in this

manual. Through sawing operations are those

in which the blade cuts completely through the

workpiece as in ripping or cross cutting.

NEVER use the tool with a faulty blade guard

or secure the blade guard with a rope, string,