10 ENGLISH

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listed below may result in electric shock, re and/or

serious injury.

Save all warnings and instruc-

tions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Safety instructions for table saws

Guarding related warnings

1. Keep guards in place. Guards must be in work-

ing order and be properly mounted. A guard

that is loose, damaged, or is not functioning cor-

rectly must be repaired or replaced.

2. Make sure the saw blade is not contacting the

guard, riving knife or the workpiece before the

switch is turned on. Inadvertent contact of these

items with the saw blade could cause a hazardous

condition.

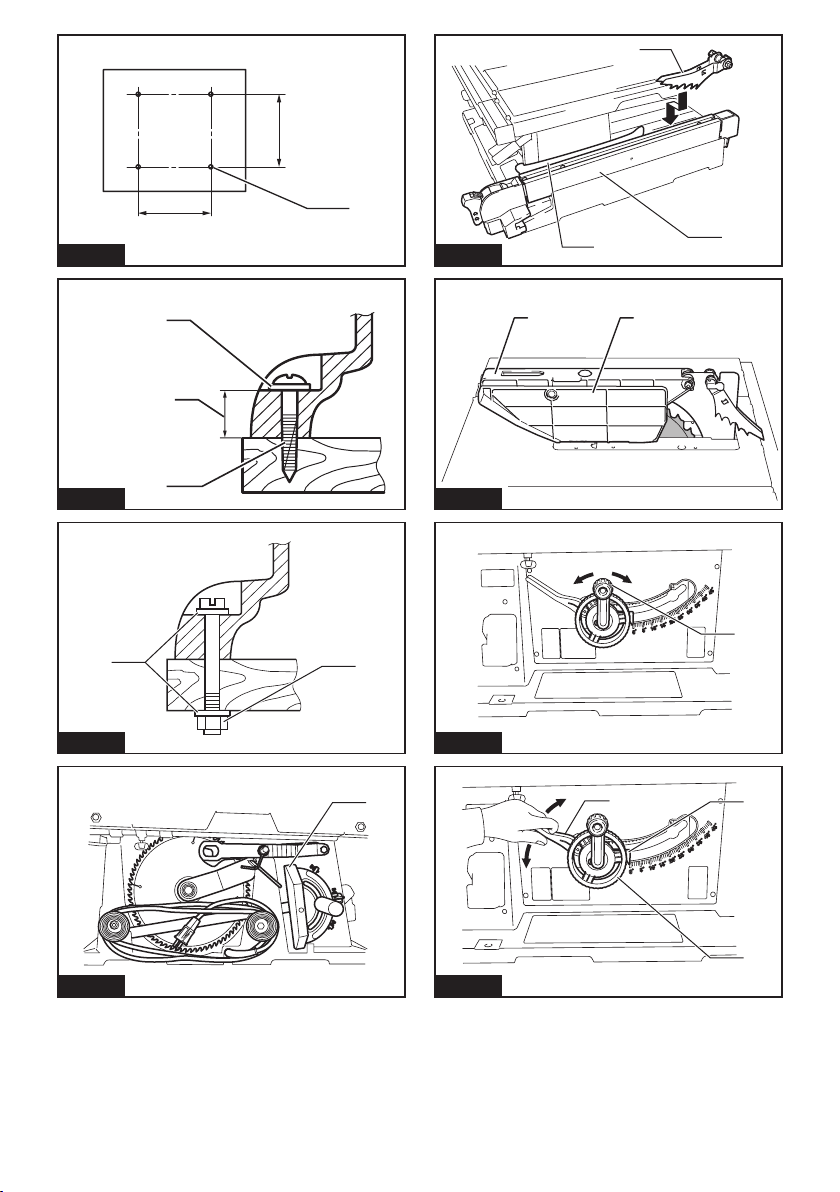

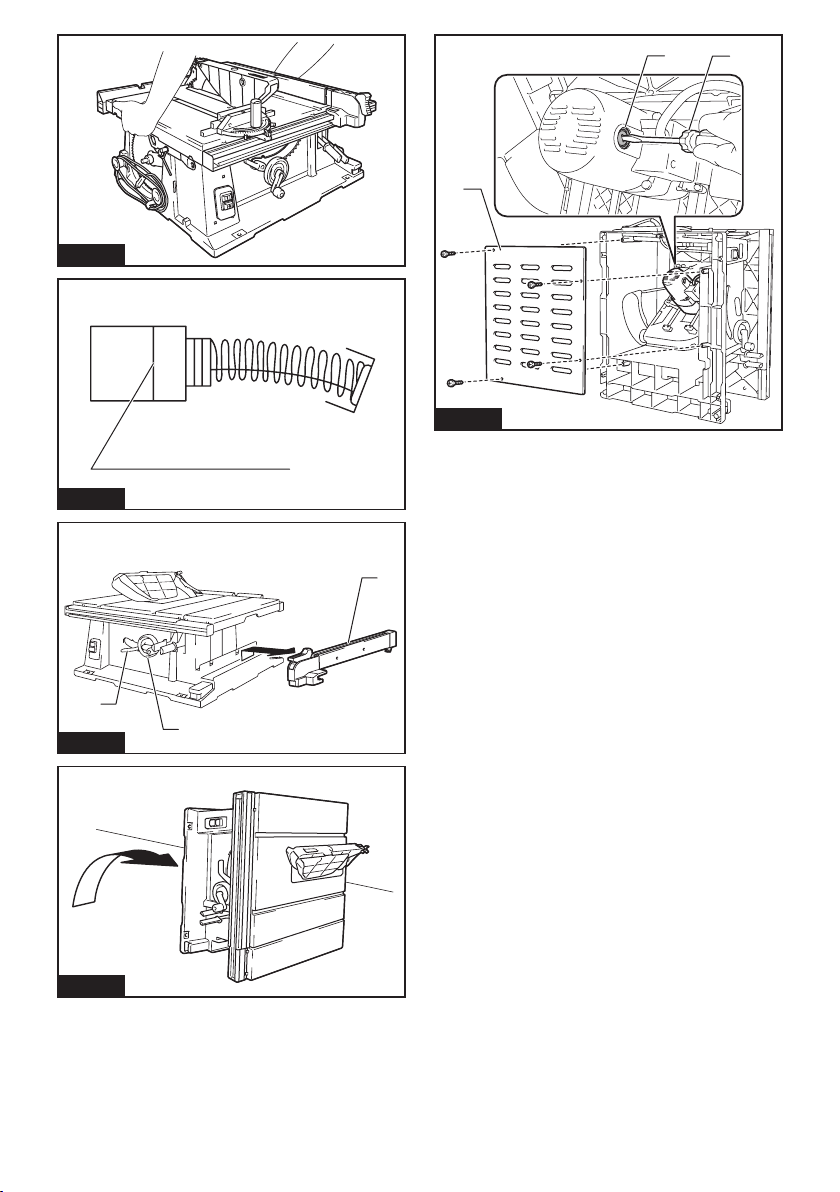

3. Adjust the riving knife as described in this

instruction manual. Incorrect spacing, position-

ing and alignment can make the riving knife inef-

fective in reducing the likelihood of kickback.

4. For the riving knife and anti-kickback pawls to

work, they must be engaged in the workpiece.

The riving knife and anti-kickback pawls are inef-

fective when cutting workpieces that are too short

to be engaged with the riving knife and anti-kick-

back pawls. Under these conditions a kickback

cannot be prevented by the riving knife and anti-

kickback pawls.

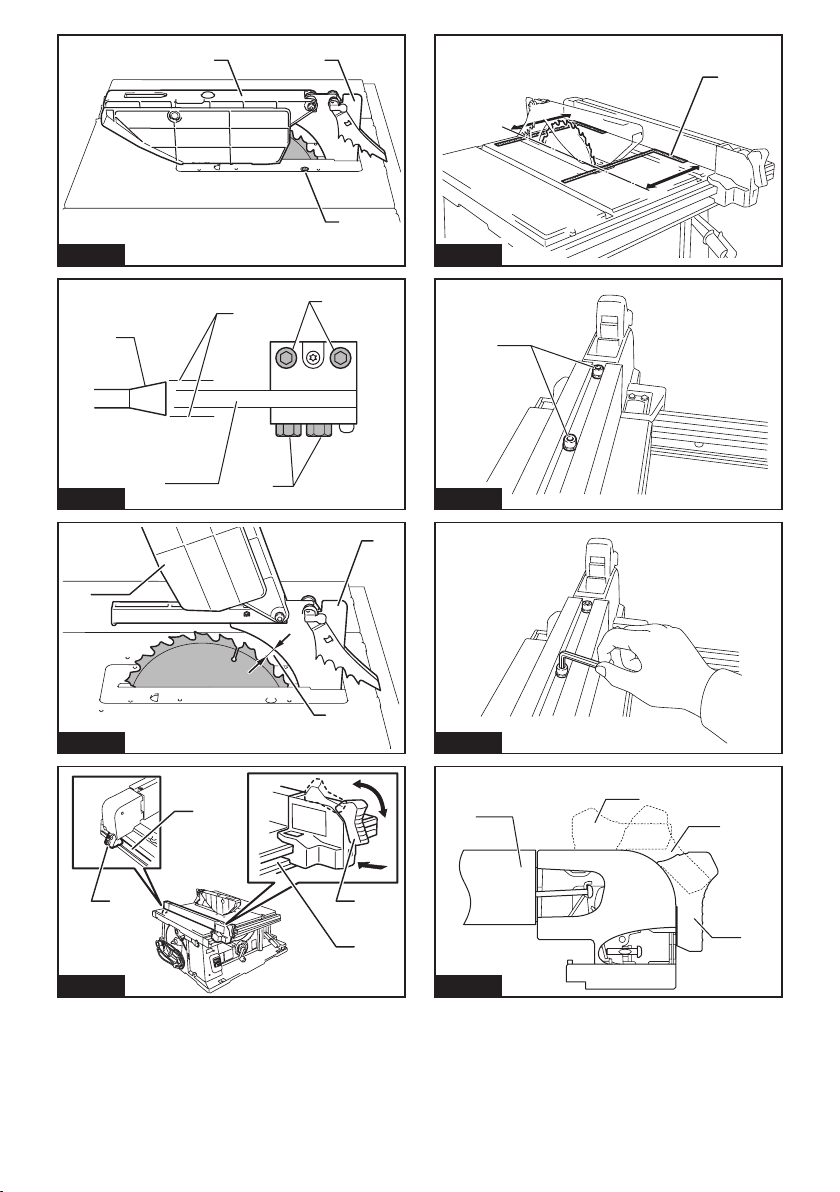

5. Use the appropriate saw blade for the riving

knife. For the riving knife to function properly, the

saw blade diameter must match the appropriate

riving knife and the body of the saw blade must be

thinner than the thickness of the riving knife and

the cutting width of the saw blade must be wider

than the thickness of the riving knife.

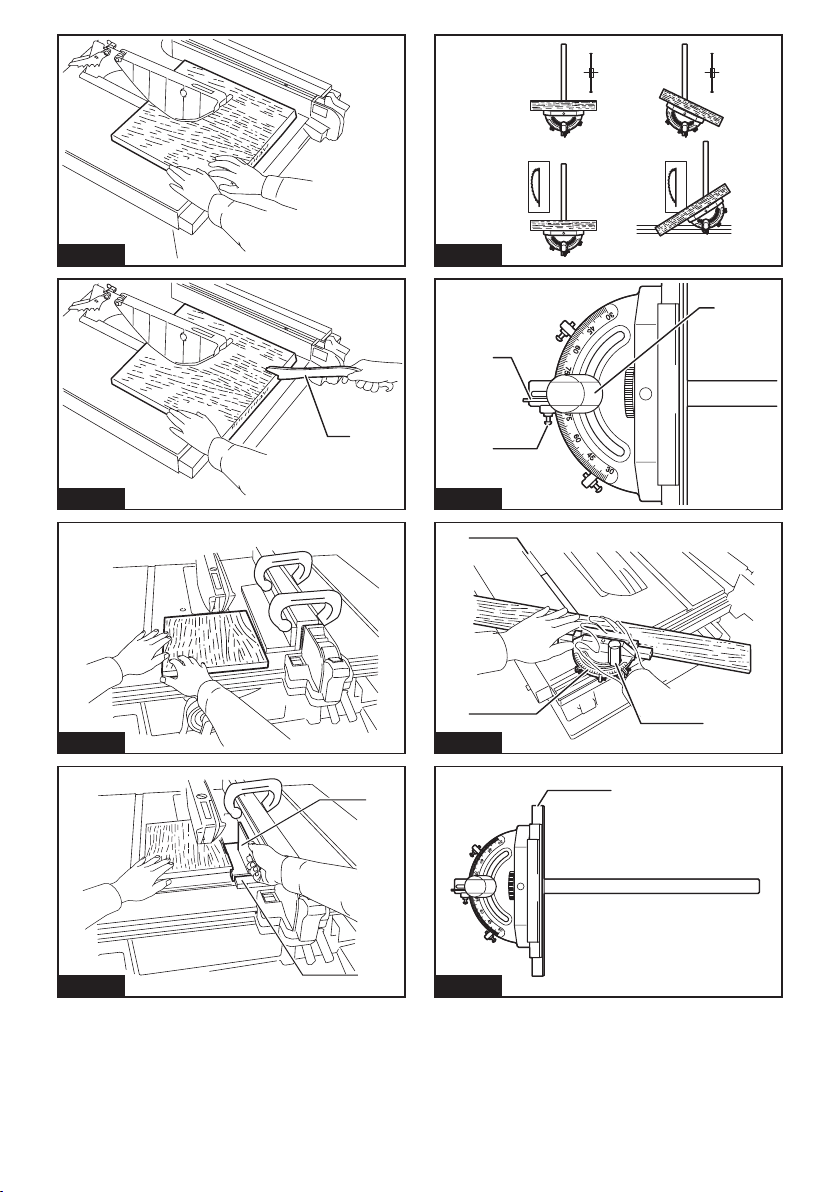

Cutting procedures warnings

1. DANGER: Never place your ngers or

hands in the vicinity or in line with the saw

blade. A moment of inattention or a slip could

direct your hand towards the saw blade and result

in serious personal injury.

2. Feed the workpiece into the saw blade only

against the direction of rotation. Feeding the

workpiece in the same direction that the saw blade

is rotating above the table may result in the work-

piece, and your hand, being pulled into the saw

blade.

3. Never use the mitre gauge to feed the work-

piece when ripping and do not use the rip

fence as a length stop when cross cutting with

the mitre gauge. Guiding the workpiece with the

rip fence and the mitre gauge at the same time

increases the likelihood of saw blade binding and

kickback.

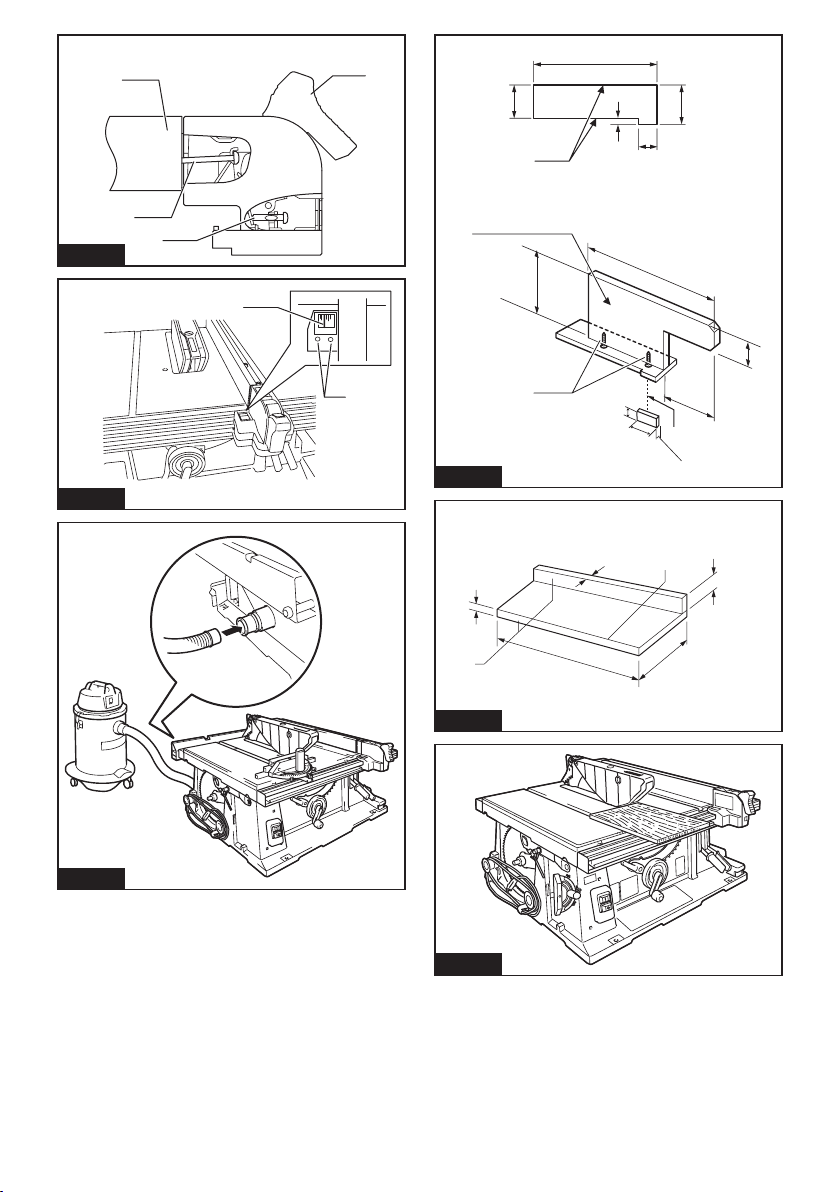

4. When ripping, always apply the workpiece

feeding force between the fence and the saw

blade. Use a push stick when the distance

between the fence and the saw blade is less

than 150 mm, and use a push block when this

distance is less than 50 mm. “Work helping”

devices will keep your hand at a safe distance

from the saw blade.

5. Use only the push stick provided by the manu-

facturer or constructed in accordance with the

instructions. This push stick provides sufcient

distance of the hand from the saw blade.

6. Never use a damaged or cut push stick. A

damaged push stick may break causing your hand

to slip into the saw blade.

7. Do not perform any operation “freehand”.

Always use either the rip fence or the mitre

gauge to position and guide the workpiece.

“Freehand” means using your hands to support or

guide the workpiece, in lieu of a rip fence or mitre

gauge. Freehand sawing leads to misalignment,

binding and kickback.

8. Never reach around or over a rotating saw

blade. Reaching for a workpiece may lead to

accidental contact with the moving saw blade.

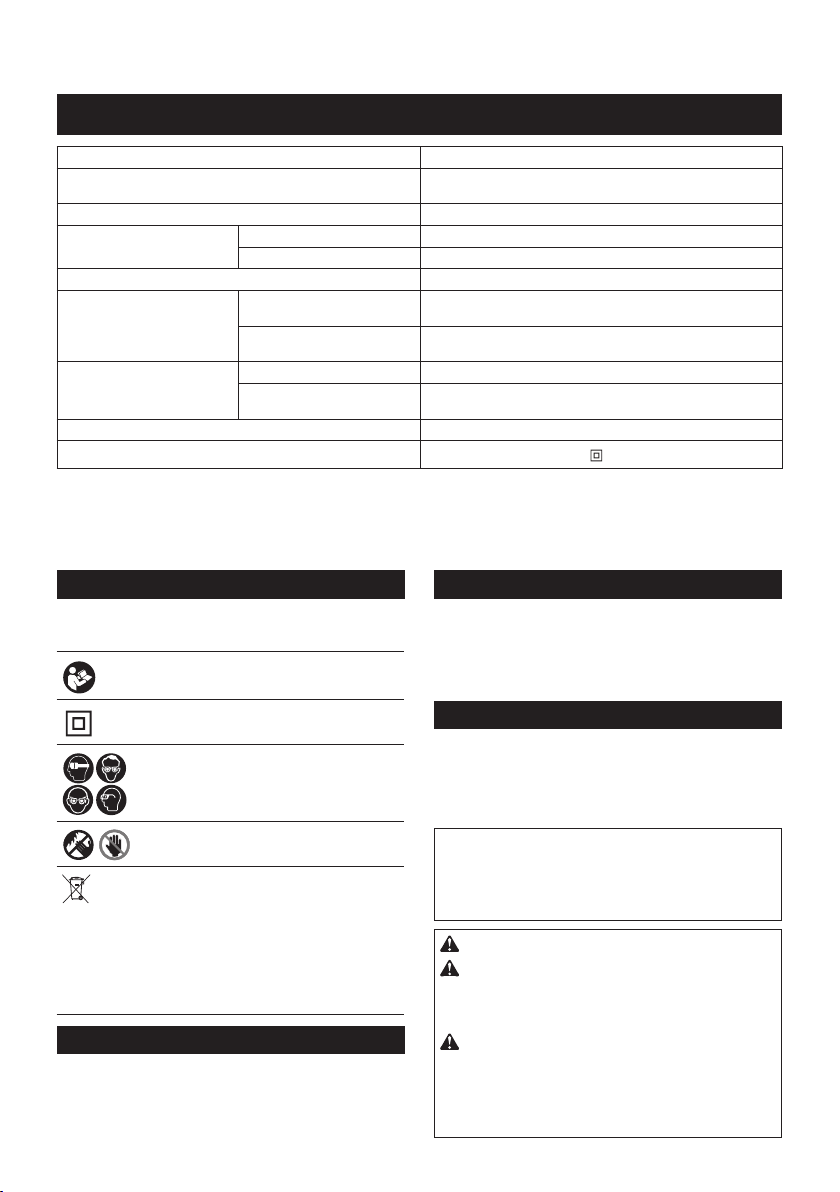

9. Provide auxiliary workpiece support to the rear

and/or sides of the saw table for long and/or

wide workpieces to keep them level. A long and/

or wide workpiece has a tendency to pivot on the

table’s edge, causing loss of control, saw blade

binding and kickback.

10. Feed workpiece at an even pace. Do not bend

or twist the workpiece. If jamming occurs, turn

the tool off immediately, unplug the tool then

clear the jam. Jamming the saw blade by the

workpiece can cause kickback or stall the motor.

11. Do not remove pieces of cut-off material while

the saw is running. The material may become

trapped between the fence or inside the saw blade

guard and the saw blade pulling your ngers into

the saw blade. Turn the saw off and wait until the

saw blade stops before removing material.

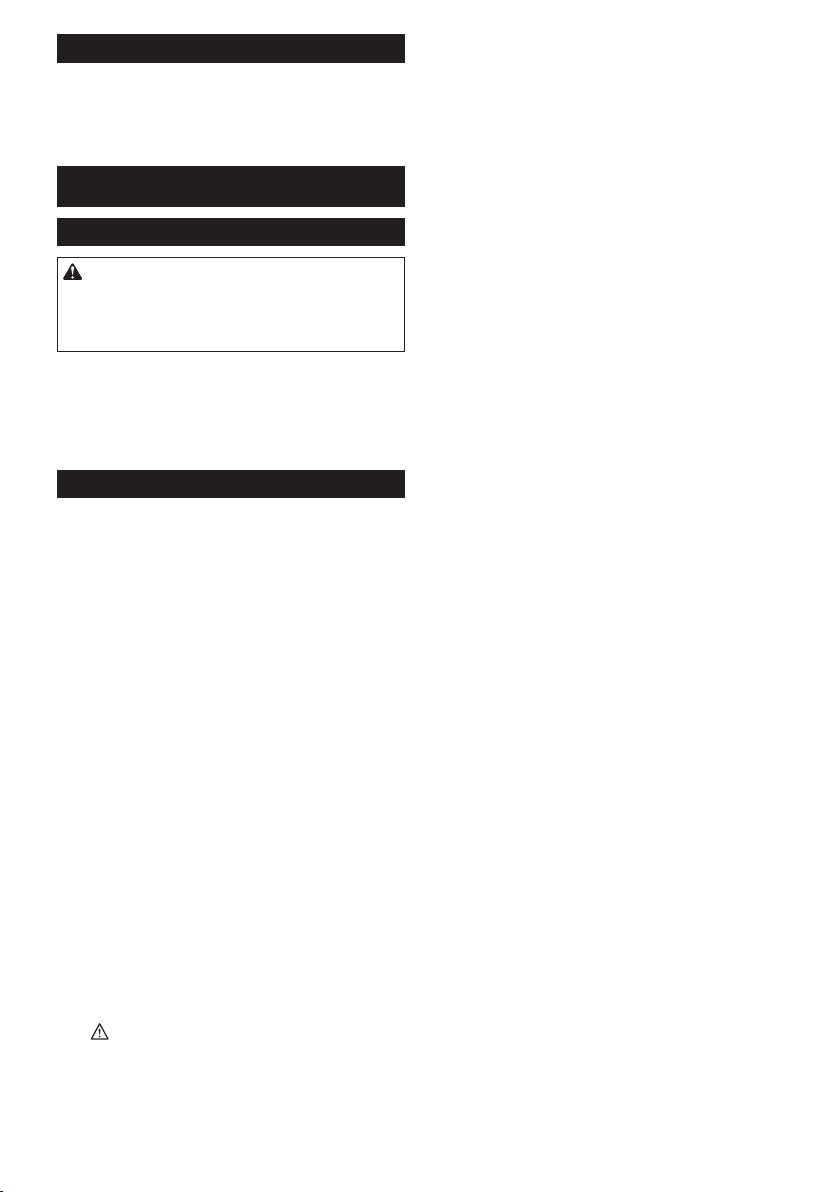

12. Use an auxiliary fence in contact with the table

top when ripping workpieces less than 2 mm

thick. A thin workpiece may wedge under the rip

fence and create a kickback.

Kickback causes and related warnings

Kickback is a sudden reaction of the workpiece due to a

pinched, jammed saw blade or misaligned line of cut in

the workpiece with respect to the saw blade or when a

part of the workpiece binds between the saw blade and

the rip fence or other xed object.