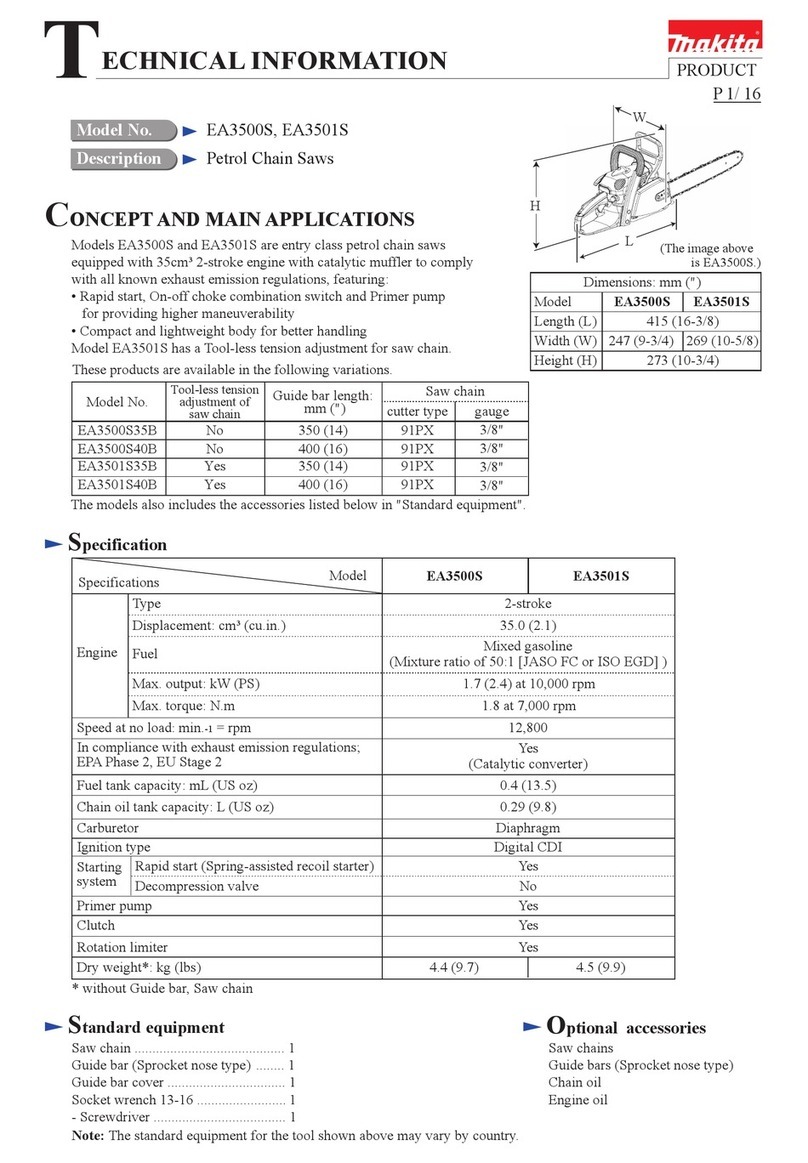

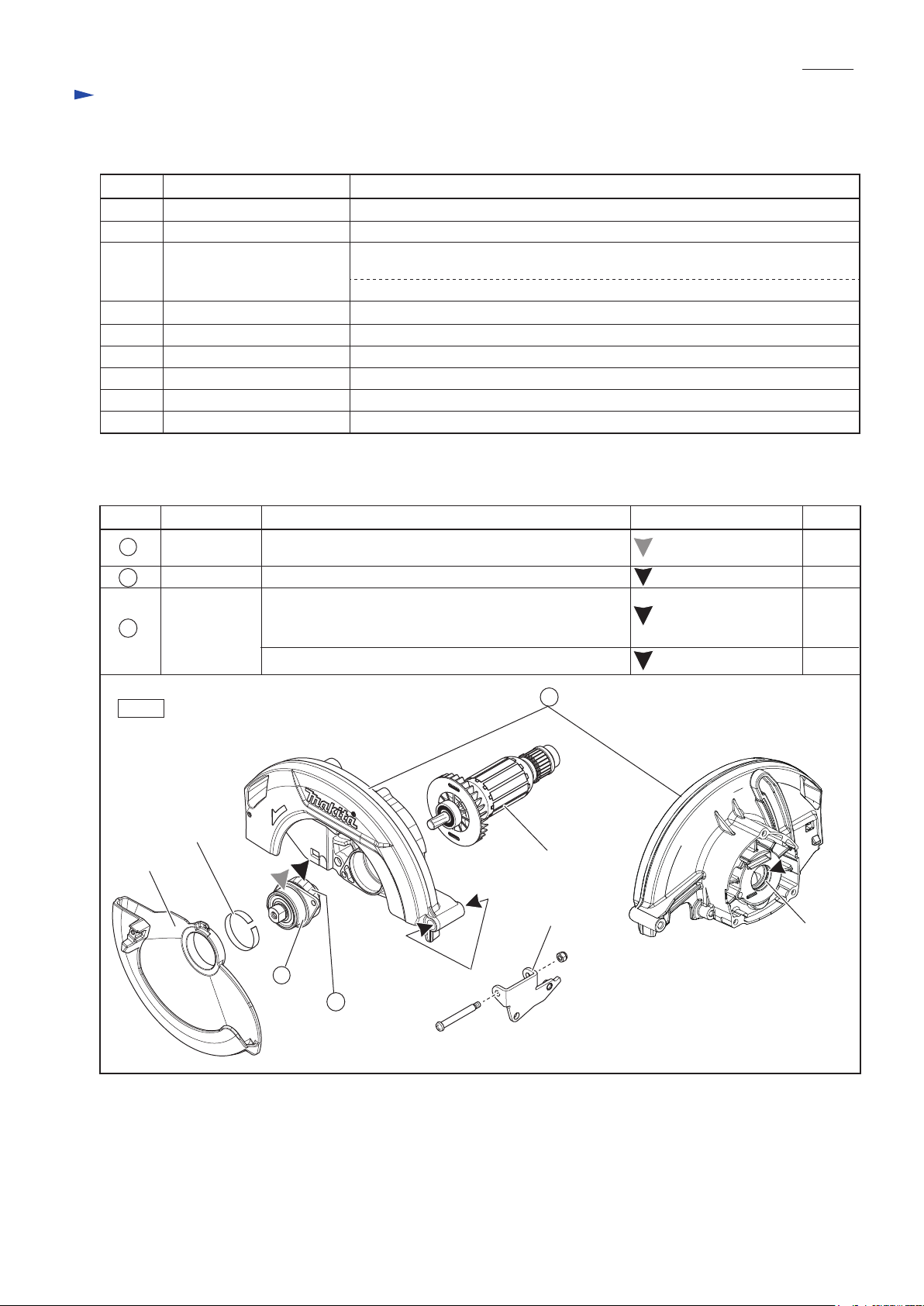

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Replacing Blade case

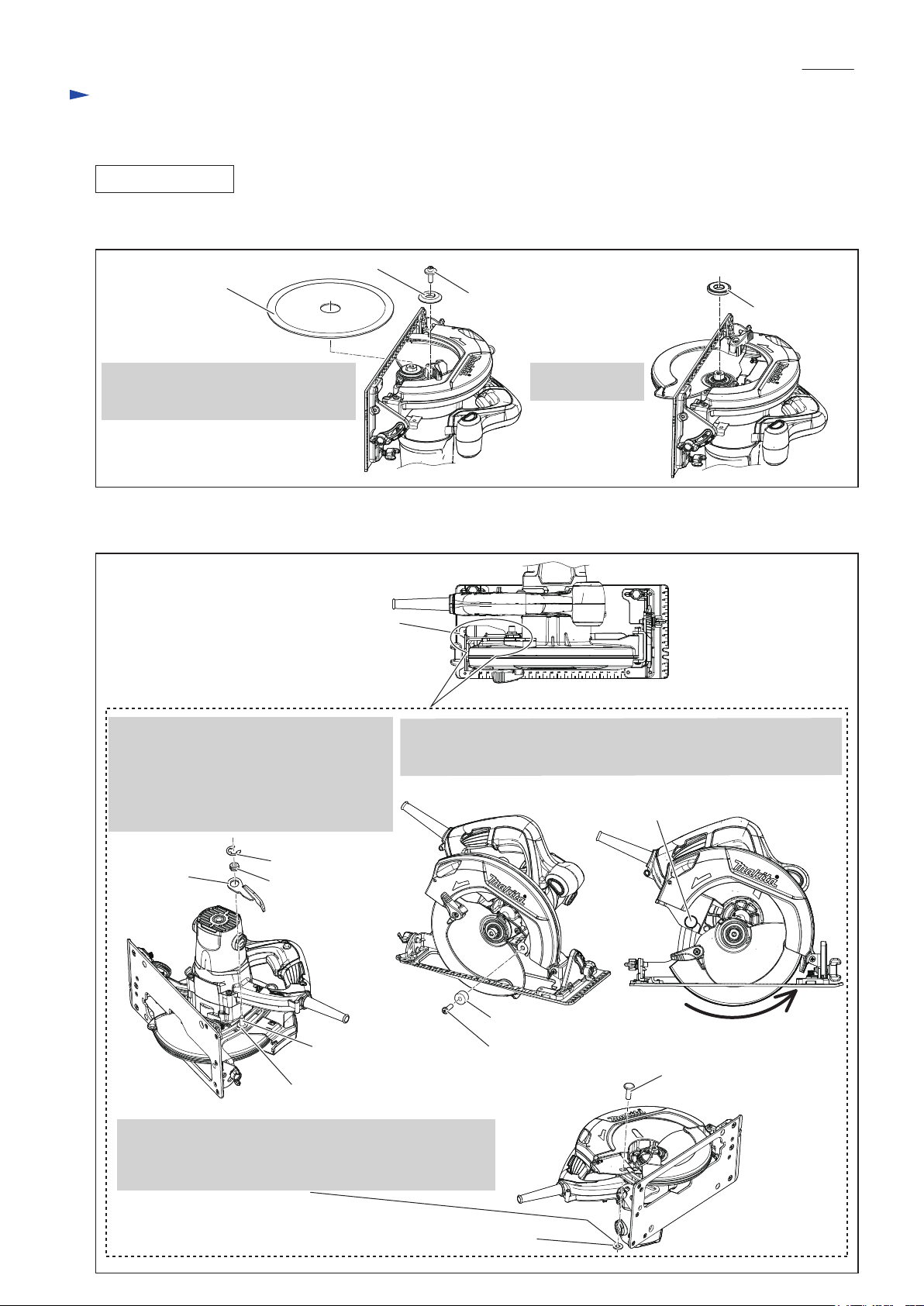

[3]-5. Adjustment

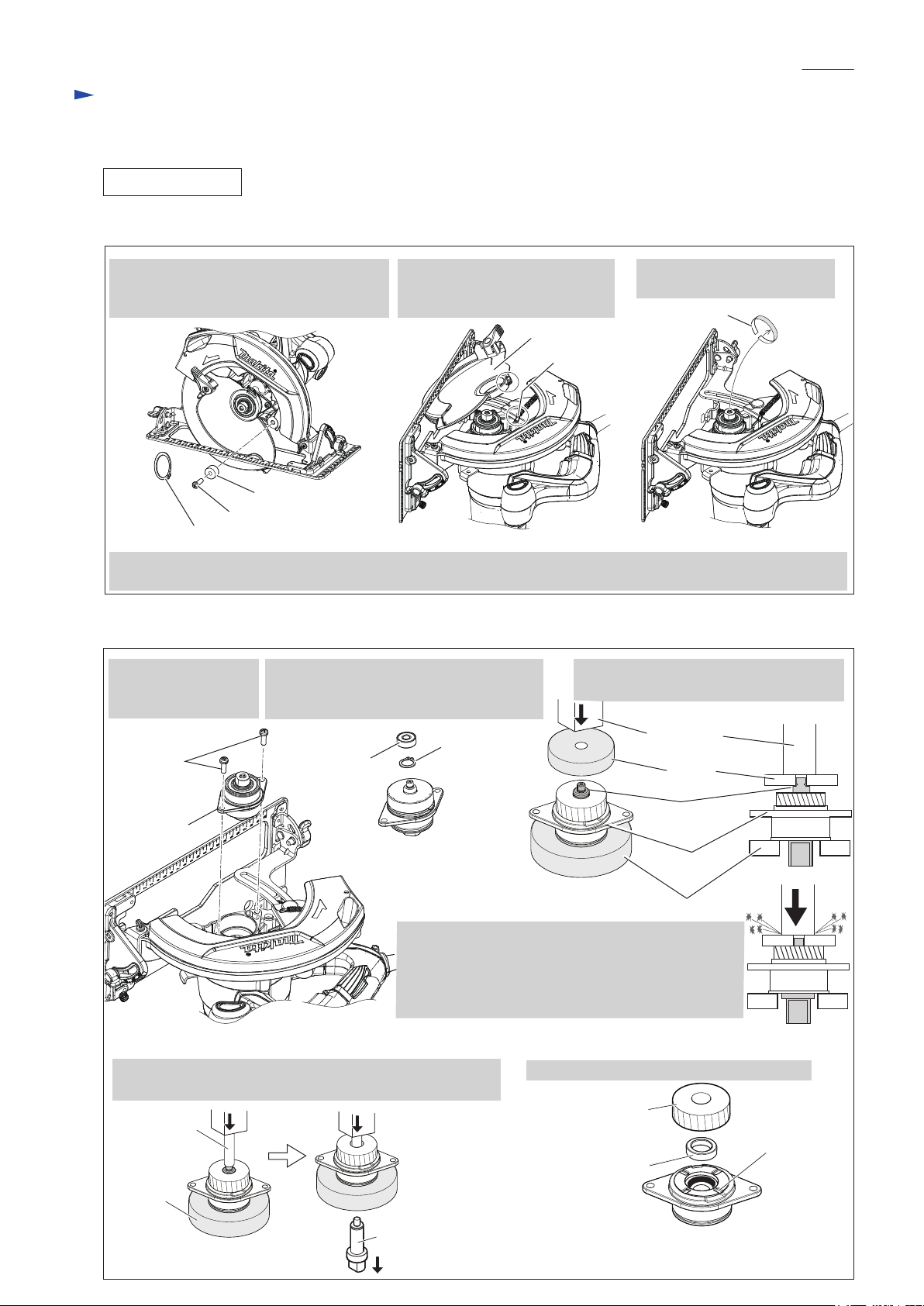

(1) Disassemble Safety cover as drawn in Fig. 7.

(2) Disassemble Bearing box section as drawn in Fig. 8.

(3) Disassemble Motor section from Blade case as drawn in Fig. 12.

(4) Disassemble Base as drawn in Figs. 3 and 4. Blade case can be replaced.

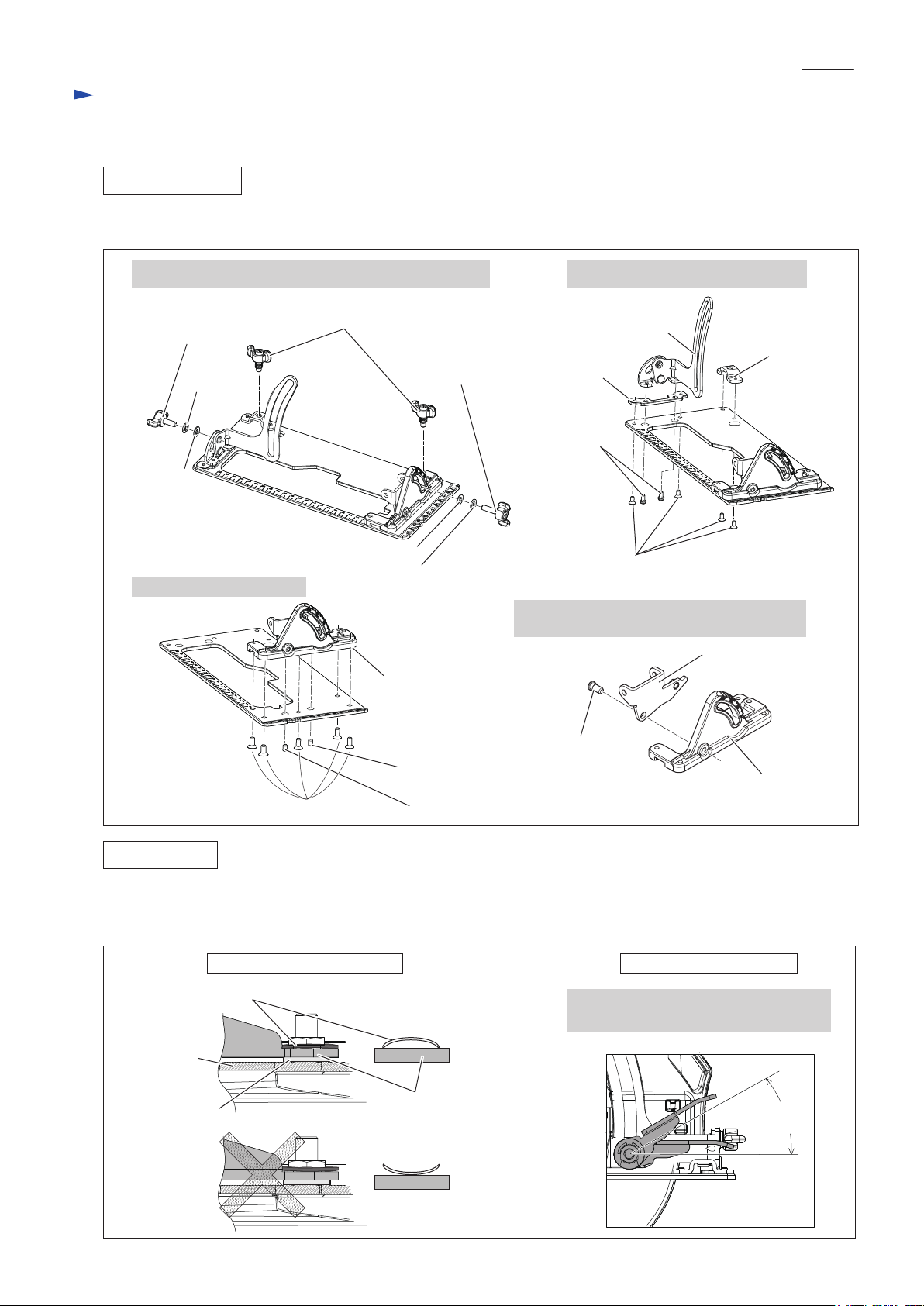

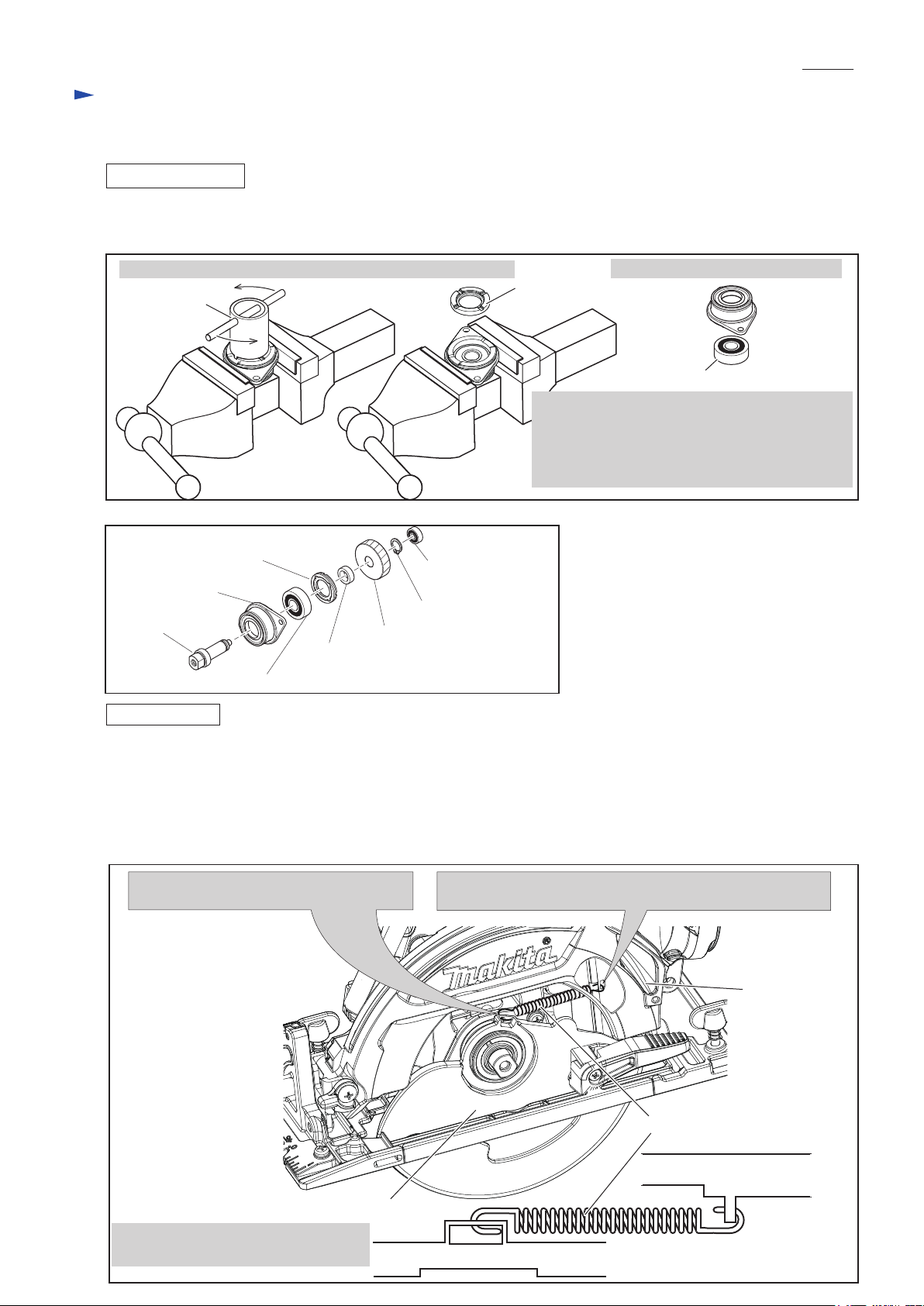

1.Insert 1R048 into the clearance between

Blade case and Lever 37 so as to hold

Safety cover and ensure the access to Blade.

Note: Make sure that Safety cover does not

move before doing step 2.

2. Apply the block of 1R208 to Base and adjust accuracy of

90° by turning M5x8 Hex socket set screw with Hex wrench 2.5

until the ruler plate of 1R208 touches Saw blade.

1R208

Block of 1R208

Ruler plate of 1R208

Saw blade

Safety cover

Hex wrench 2.5

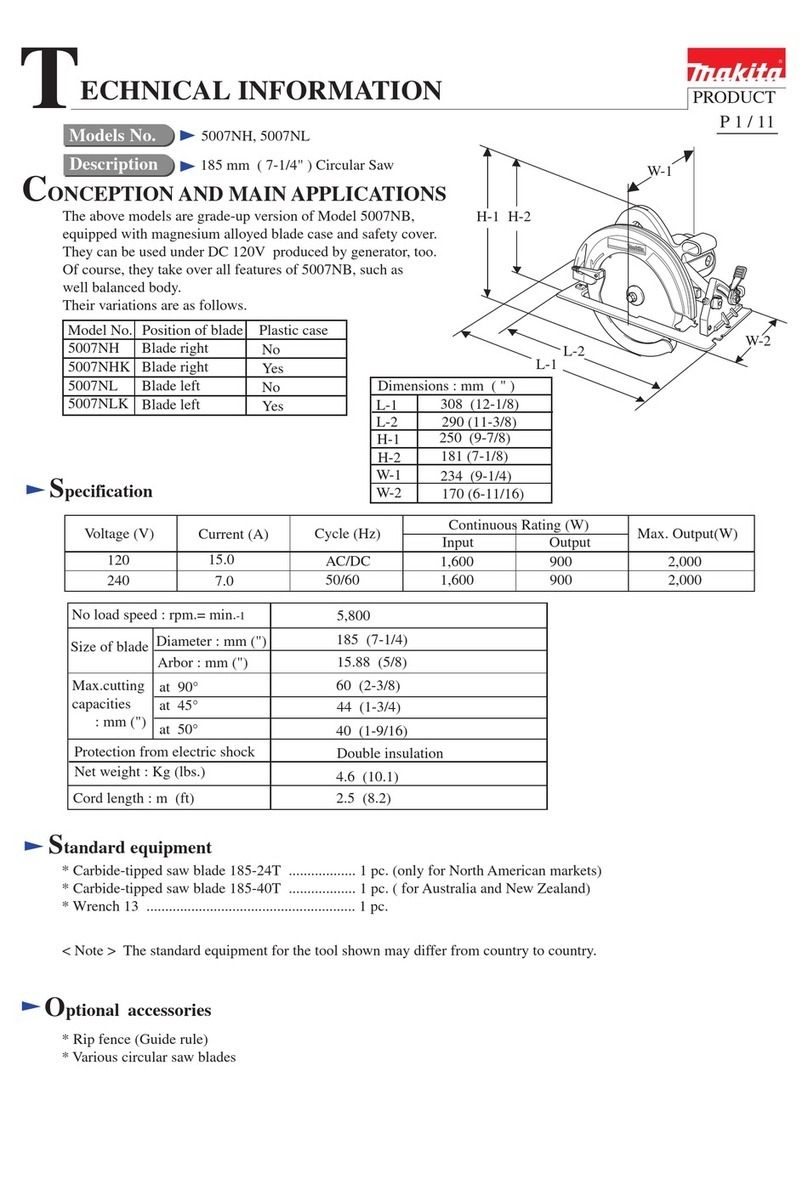

(1) Set the machine as follows.

* Bevel angle: 90°

* Cutting depth: maximum depth

And tighten M6x21 Thumb screw and Lever plate to keep the above conditions.

(2) Adjust accuracy of 90° of Base to Saw blade as drawn in Fig. 13.

(3) Adjust the base in parallel to Saw blade as drawn in Fig. 14.

1R048

Blade case

Fig. 13

Fig. 14

M5x8 Hex socket head set screw

Note: Do not turn this M5x8 Hex socket set screw. This works as

a stopper for 6-7 Shoulder pin (hinge of Angular guide).

P 9/ 11

Lever 37

M4x8 Pan head screw (2 pcs.)Cord guard side of Base

1. Unlock the cord guard side of Base from Blade case by

loosening M4x8 Pan head screw slightly.

2. Move the cord guard side of Base by hand in the direction

of yellow arrows until the distance A is equal to B.

3. After finishing the adjustment, tighten M4x8 Pan head

screw firmly.

A

B

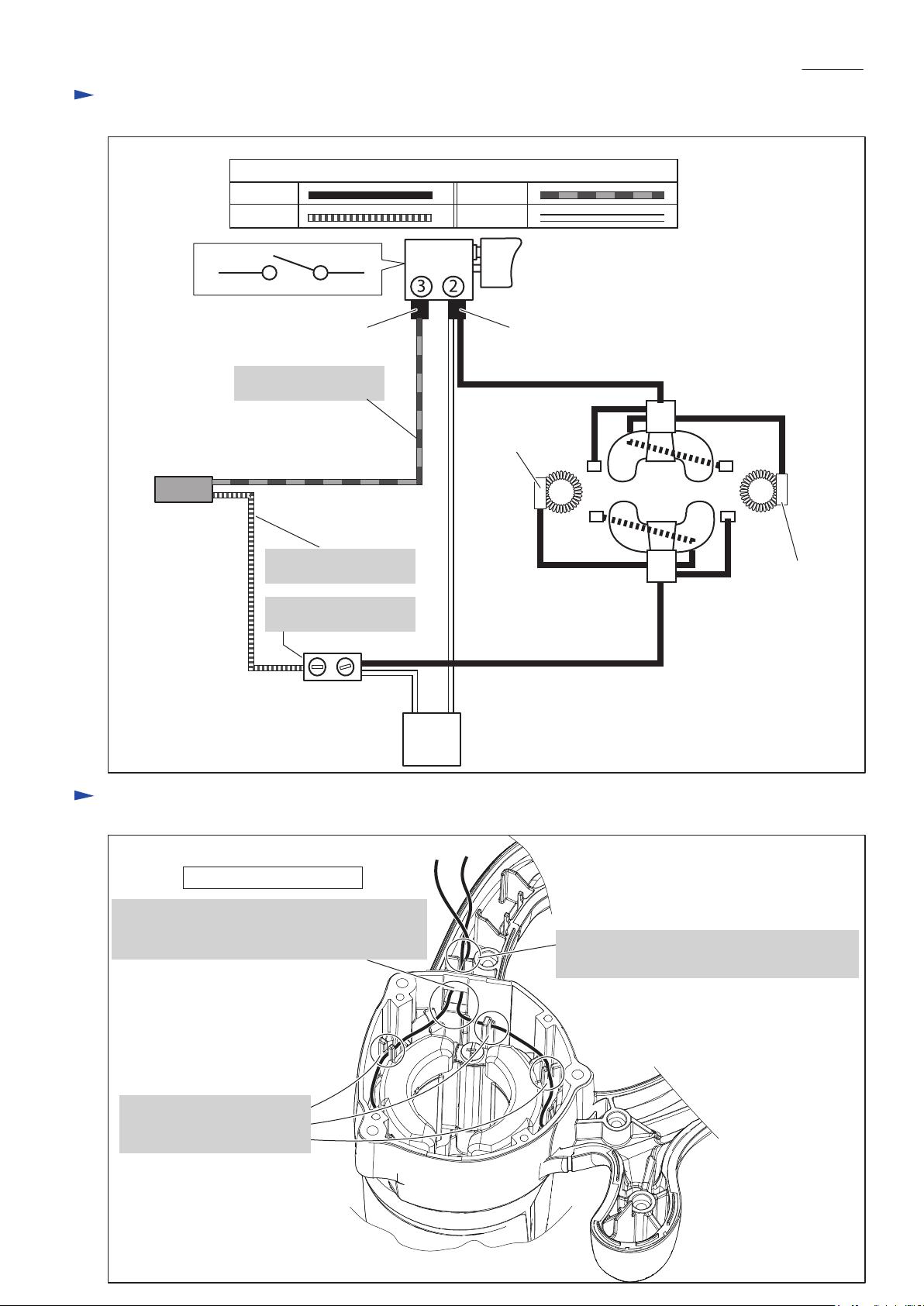

Repair