3ENGLISH

19. CHECK DAMAGED PARTS. Before further use

of the tool, a guard or other part that is dam-

aged should be carefully checked to determine

that it will operate properly and perform its

intended function - check for alignment of

moving parts, binding of moving parts, break-

age of parts, mounting, and any other condi-

tions that may affect its operation. A guard or

other part that is damaged should be properly

repaired or replaced.

20. DIRECTION OF FEED. Feed work into a blade

or cutter against the direction of rotation of the

blade or cutter only.

21. NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Do not leave tool until it

comes to a complete stop.

22. REPLACEMENT PARTS. When servicing, use

only identical replacement parts.

23. POLARIZED PLUGS. To reduce the risk of elec-

tric shock, this equipment has a polarized plug

(one blade is wider than the other). This plug

will t in a polarized outlet only one way. If the

plug does not t fully in the outlet, reverse the

plug. If it still does not t, contact a qualied

electrician to install the proper outlet. Do not

change the plug in any way.

VOLTAGE WARNING: Before connecting the tool

to a power source (receptacle, outlet, etc.) be sure

the voltage supplied is the same as that specied

on the nameplate of the tool. A power source with

voltage greater than that specied for the tool can

result in SERIOUS INJURY to the user- as well as

damage to the tool. If in doubt, DO NOT PLUG IN

THE TOOL. Using a power source with voltage less

than the nameplate rating is harmful to the motor.

USE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An under-

sized cord will cause a drop in line voltage resulting

in loss of power and overheating. Table 1 shows the

correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the

heavier the cord.

Table 1: Minimum gage for cord

Ampere Rating Volts Total length of cord in feet

120V 25 ft. 50 ft. 100 ft. 150 ft.

220V - 240V 50 ft. 100 ft. 200 ft. 300 ft.

More Than Not More Than AWG

06–18 16 16 14

610 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

Additional safety rules

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adher-

ence to miter saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious per-

sonal injury.

1. Wear eye protection.

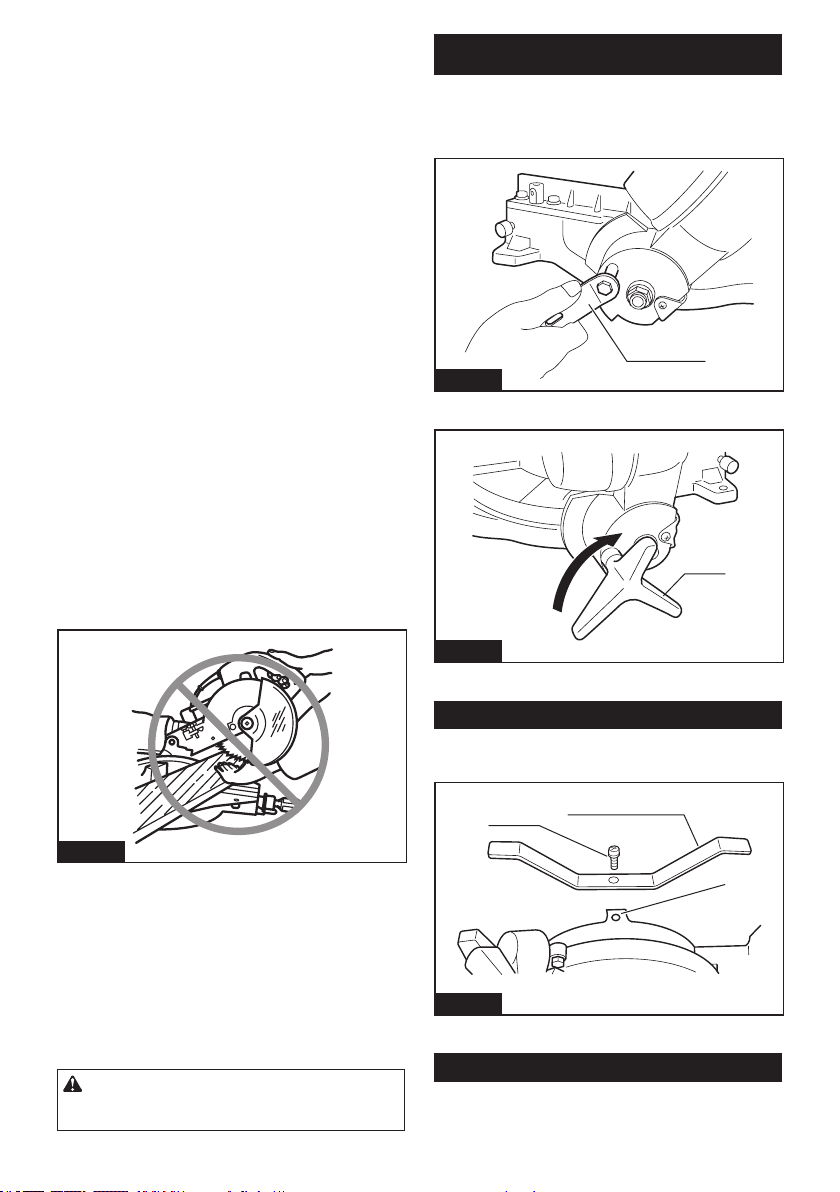

2. Keep hands out of path of saw blade. Avoid

contact with any coasting blade. It can still

cause severe injury.

3. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly.

Never clamp or tie the blade guard into the

open position.

4. Do not perform any operation freehand. The

workpiece must be secured rmly against the

turn base and guide fence with a vise during

all operations. Never use your hand to secure

the workpiece.

5. Never reach around saw blade.

6. Turn off tool and wait for saw blade to stop

before moving workpiece or changing

settings.

7. Unplug tool before changing blade or

servicing.

8. Always secure all moving portions before

carrying the tool.

9. Do not use the tool in the presence of amma-

ble liquids or gases.

10. Check the blade carefully for cracks or damage

before operation. Replace cracked or damaged

blade immediately. Gum and wood pitch hard-

ened on blades slows saw and increases potential

for kickback. Keep blade clean by rst removing

it from tool, then cleaning it with gum and pitch

remover, hot water or kerosene. Never use gaso-

line to clean blade.

11. Use only anges specied for this tool.

12.

Be careful not to damage the arbor, anges

(especially the installing surface) or bolt. Damage

to these parts could result in blade breakage.

13. Make sure that the turn base is properly

secured so it will not move during operation.

Use the holes in the base to fasten the saw to a

stable work platform or bench. NEVER use tool

where operator positioning would be awkward.

14. For your safety, remove the chips, small

pieces, etc. from the table top before

operation.