2

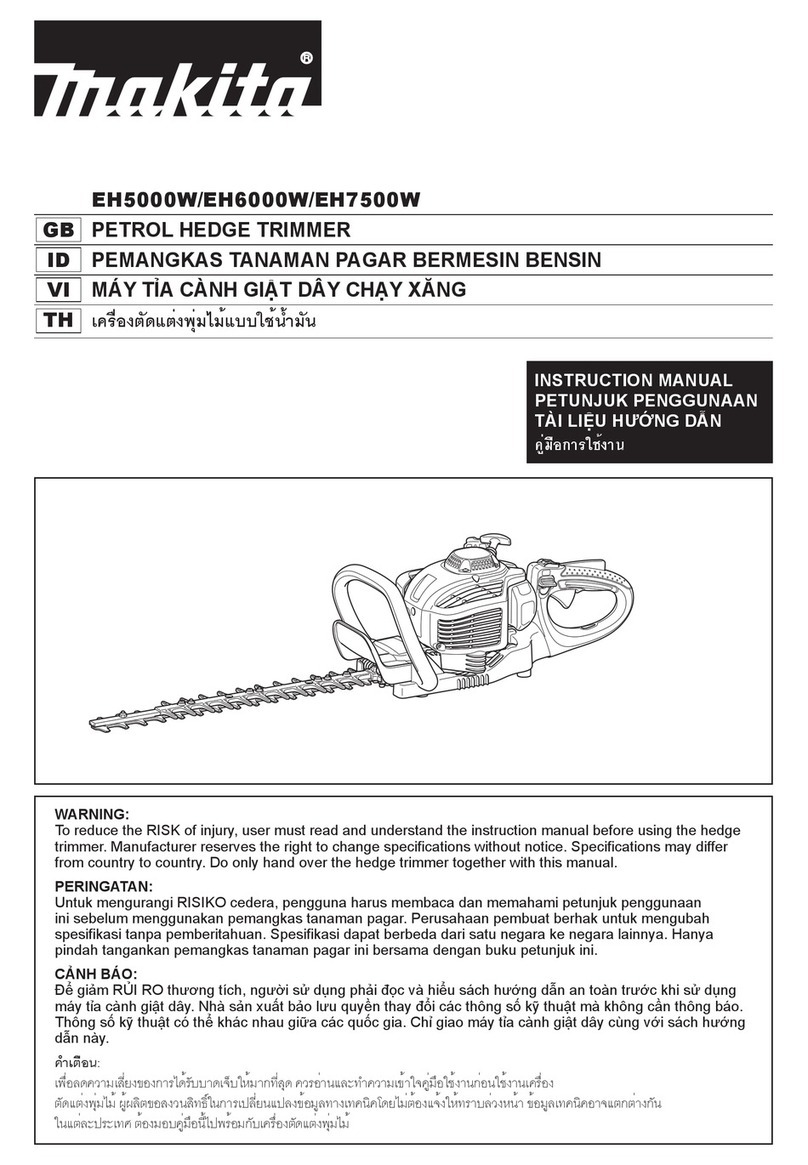

Thank you for choosing a MAKITA product!

We trust that you will be a satisÞed customer. By choosing a

MAKITA you have chosen one of the most advanced brush-

cutters.

TheDBC340brushcuttercombinesthebeneÞtsofstate-of-the-art

technology, ergonomic design and highly convenient operation

at a low initial cost. The engine of the DBC340 brushcutter, with

its optimum cylindrical design, computerized control times and

maintenance-free electronic ignition, has long been a feature

of proven quality in the professional MAKITA DBC3310 brush-

cutter. It is characterized by its high performance and compa-

ratively low fuel consumption.

The drive shaft is designed for continuous heavy-duty use,

with 7 bearings and a tough centrifugal clutch. Four conical

hollow absorption elements between the main tube and the

handles reduce felt vibration to a minimum, for comfortable,

untiring long-term working. All important controls are located

on the right handle for ease of operation.

The following industrial property rights apply: US 512606,

EP 0696414, GBM 9412925.

To ensure your own safety and to get the maximum performance

out of your MAKITA brushcutter, we urge you to

read this instruction manual carefully before putting the

brushcutter into operation and to strictly observe all of

the safety regulations. Failure to do so can result in serious

injury to the operator and/or bystanders!

Table of contents Page

Packing ................................................................................2

Delivery inventory ..............................................................3

Explanation of symbols .....................................................3

SAFETY PRECAUTIONS

General precautions ....................................................... 4

Personal protective equipment ....................................... 4

Handling fuels / Refuelling ..............................................5

Putting into operation ...................................................5-6

Kickback .........................................................................6

Working behavior / Method of working ............................7

Applications for cutting tools............................................ 7

Transport..........................................................................7

Storage ...........................................................................8

Maintenance ...................................................................8

First Aid ...........................................................................8

Technical data .....................................................................9

Components ........................................................................9

PUTTING INTO OPERATION

Mounting the tube handle ............................................. 10

Mounting the cutter guard ........................................ 10-11

Installing the Cutting Tools

Mounting the 4-tooth star blade .................................... 11

Mounting the 8-tooth eddy blade (accessory) ............... 11

Mounting the steel bush cutter (accessory) .................. 11

Installing the trimmer head (accessory) ........................12

Installing the line cutter .................................................1 2

Lengthening the line ......................................................12

Fuel mixture / Refuelling ................................................ 13

Putting on the harness...................................................14

Balancing the brushcutter .............................................14

Start engine .................................................................. 15

Adjusting idling speed ...................................................15

REPAIR AND MAINTENANCE WORK

Instructions for maintenance ......................................... 16

Sharpening of cutting tools ........................................... 16

Starter cable replacement ............................................. 17

Replacing the return spring ........................................... 17

Cleaning the air Þlter .....................................................18

Inspecting and replacing the spark plug ....................... 18

Replacing the suction head .......................................... 19

Trouble shooting ..............................................................19

Service, spare parts and guarantee ................................ 20

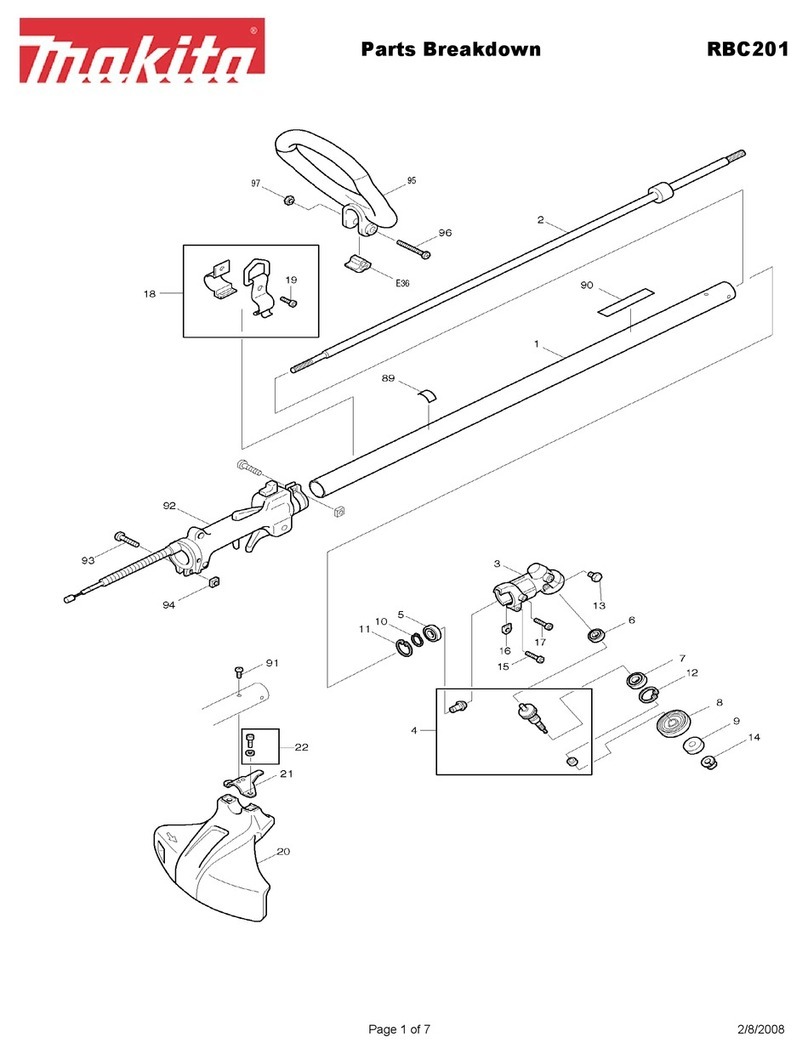

Extract from the spare part list .......................................21

EU conformity declaration ............................................... 21

Notes .............................................................................22-23

Packing

Your MAKITA brushcutter comes in a cardboard box to

protect it from shipping damage.

Cardboard is a raw material. We encourage you to re-use

the box or recycle it (waste paper).