Model No.

Description

DVC260

Cordless Backpack Vacuum Cleaner

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

Nozzle assembly (Floor nozzle)

Flexible rubber nozzle

Hose band

Filter bag set (Paper dust bag): 10pcs/set

Dust bag assembly (Cloth dust bag)

Filter assembly (HEPA filter)

Round brush

Shelf brush

Flexible hose

Carpet nozzle

Battery BL1815N

Battery BL1820

Battery BL1820B

Battery BL1830

Battery BL1830B

Battery BL1840

Battery BL1840B

Battery BL1850

Battery BL1850B

Battery BL1860B

Fast charger DC18RC

Charger DC18SD/DC24SC

Automotive charger DC18SE

Four port multi charger DC18SF

Two port multi fast charger DC18RD

Model DVC260 is a cordless backpack vacuum cleaner powered by

two 18V Li-ion batteries in series.

The main features and benefits are:

• Long run time thanks to energy-efficient brushless DC motor

• Controller operable in hand for on/off switching and

high/low power selection, with LED job light for job in the dark

• Equipped with HEPA filter.

• Telescopic straight pipe adjustable to user’s height or various applications

• Flexible rubber nozzle, ideal for cleaning corners of stairs,

is supplied as standard.

• Reusable cloth dust bag is available as option.

Note: This model is not compatible with BL1815 (1.3Ah).

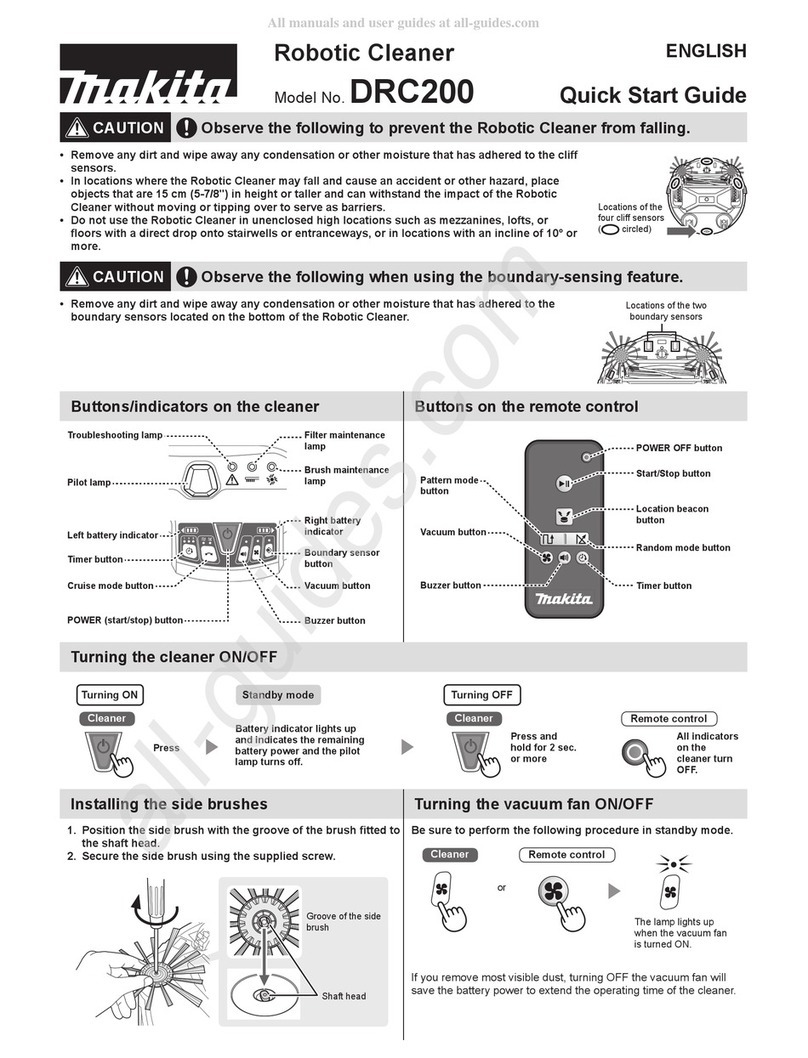

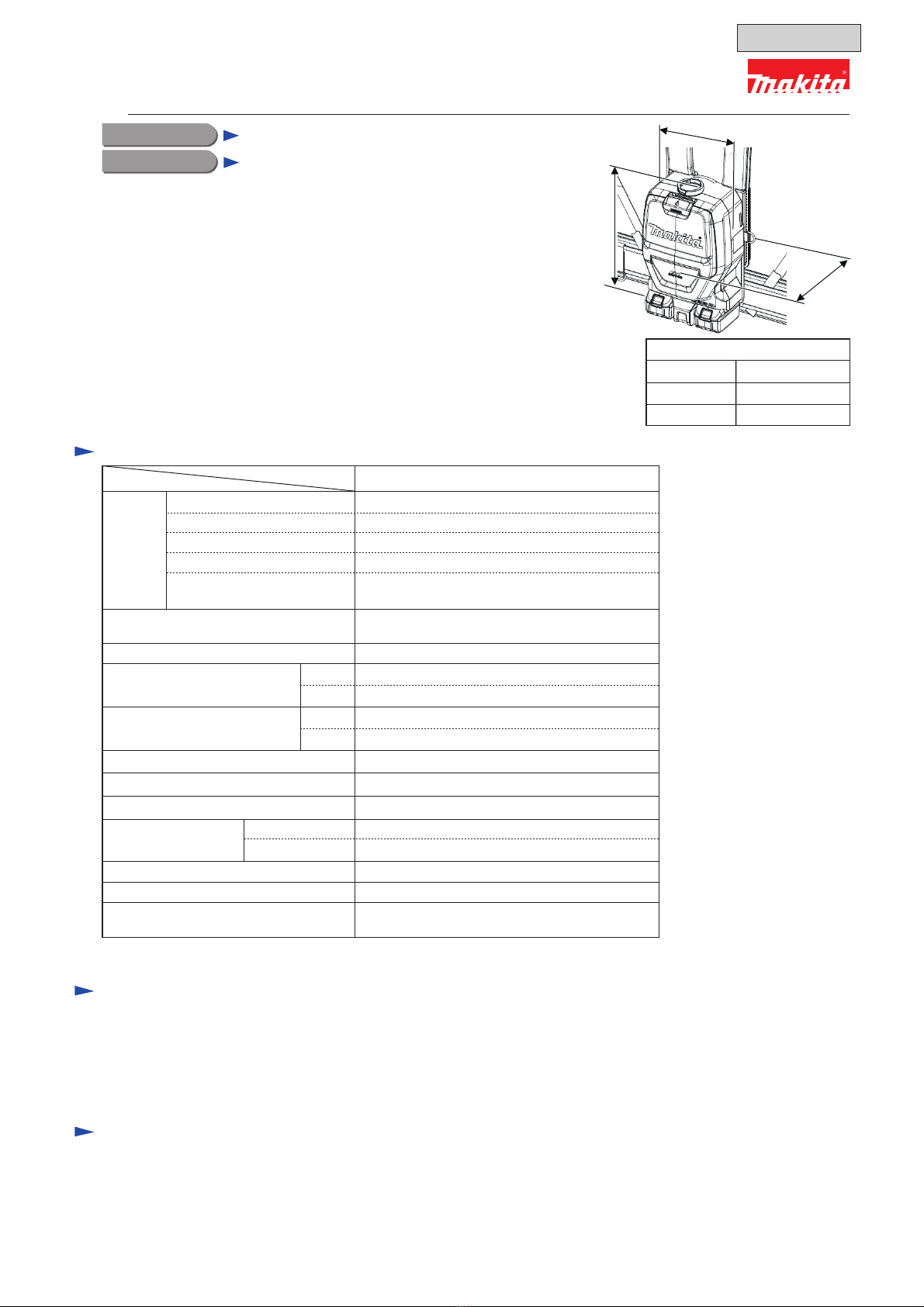

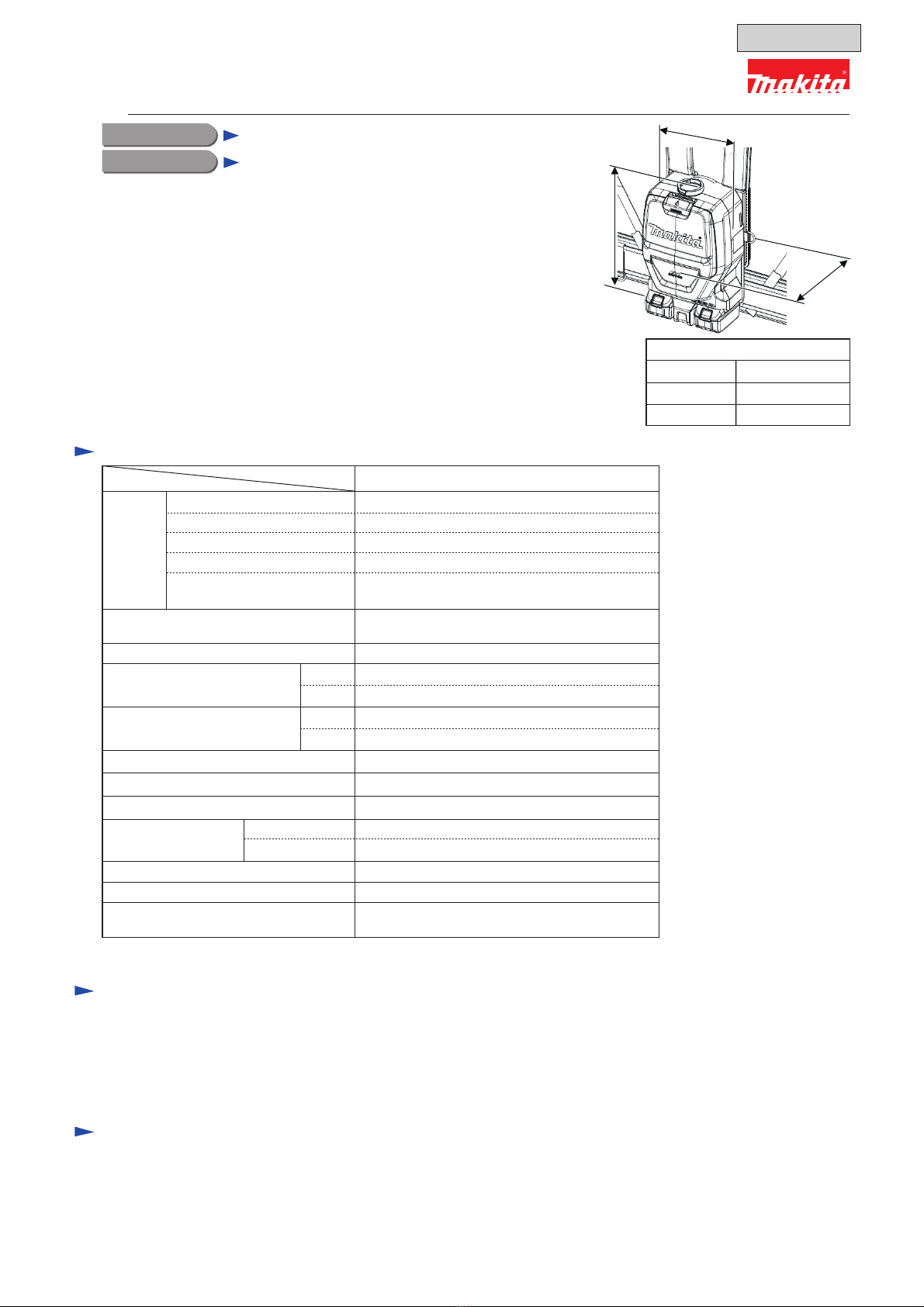

Dimensions*1: mm (")

Width (W)

Height (H)

Length (L)

152 (6)

230 (9)

373 (14-3/4)

Battery*4

Battery cover*5

Charger*4

Hose complete 28-1.0

Bent pipe assembly

Hose band

Filter bag (Paper dust bag)Nozzle assembly (Floor nozzle)

Flexible rubber nozzle

Telescopic pipe assembly

*4 Battery and charger are not supplied with “Z” model.

*5 Supplied with the same quantity of extra Battery.

Note: The standard equipment may vary by country or model variation.

W

L

H

Battery

Specification Model

Energy capacity: Wh

Voltage: V

Capacity: Ah

Cell Li-ion

Charging time (approx.): min 15x2, 24x2, 22x2, 36x2, 45x2, 55x2

with DC18RC

36 (18x2)

DVC260

Yes

Max air volume: m3/min

NoBattery capacity warning function

Yes

(High/Low)

Power selection

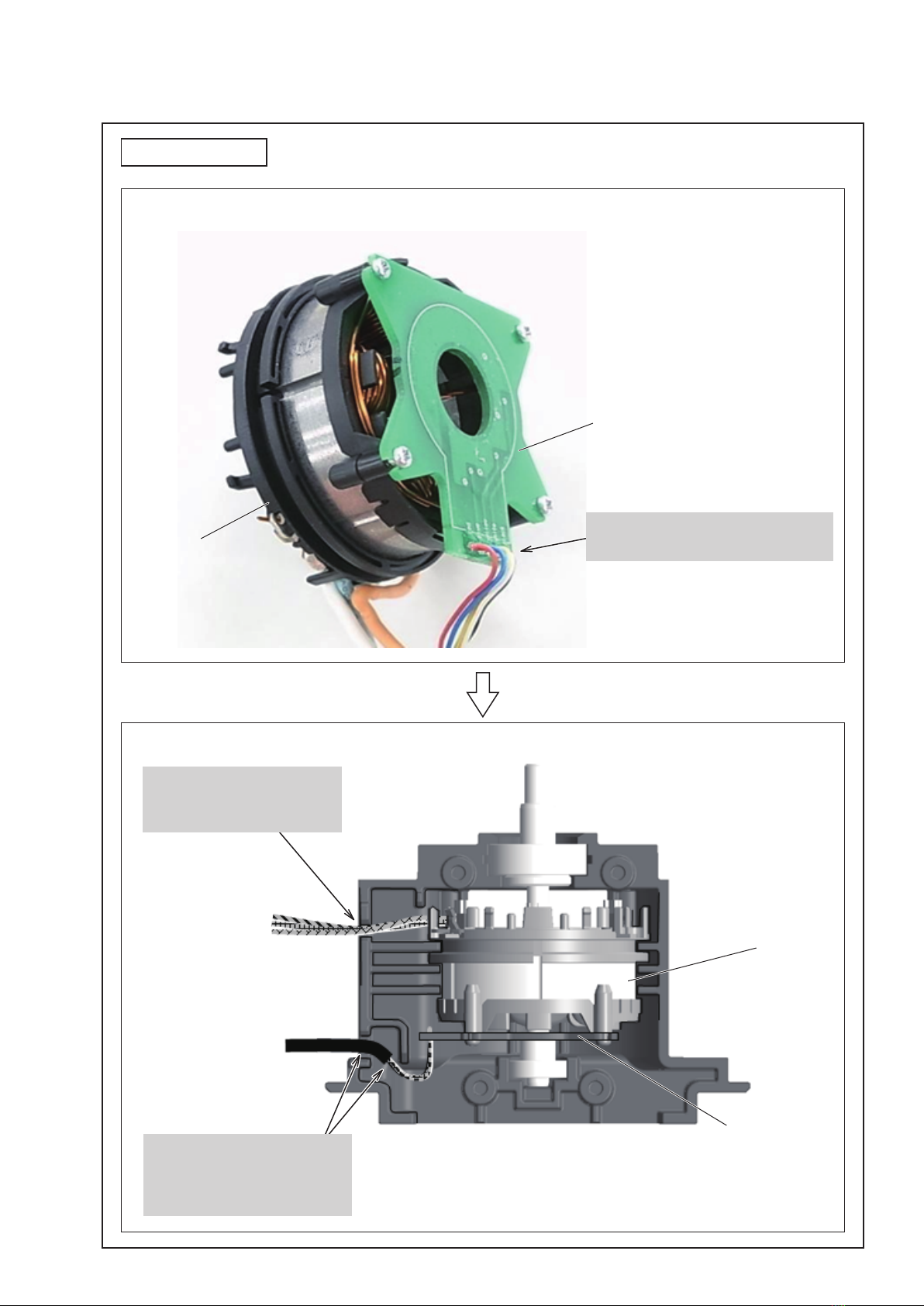

BrushlessDC motor

LED job light

Weight according to

EPTA-Procedure 01/ver.2.1: kg (lbs) 3.9 (8.7)*2, 4.3 (9.4)*3

2.0

1.5

Paper dust bag

Cloth dust bag

Dust bag capacity: L

60

90

Continuous run time (approx)

on a single full battery*1: min

1.5

Hose (standard equipment) ø28mm x 1m

1.5, 2.0, 3.0, 4.0, 5.0, 6.0

27x2, 36x2, 54x2, 72x2, 90x2, 108x2

*1 With BL1850x2 *2 With a Paper dust bag and 2 pcs of BL1815N or BL1820(B)

*3 With a Paper dust bag and 2 pcs of BL1830(B), BL1840(B), BL1850(B) or BL1860B

Suction power: W

7.1 (710)

45

25

Max sealed suction: kPa (mmH2O)

High

Low

High

Low

*1 Without Harness

March 2016

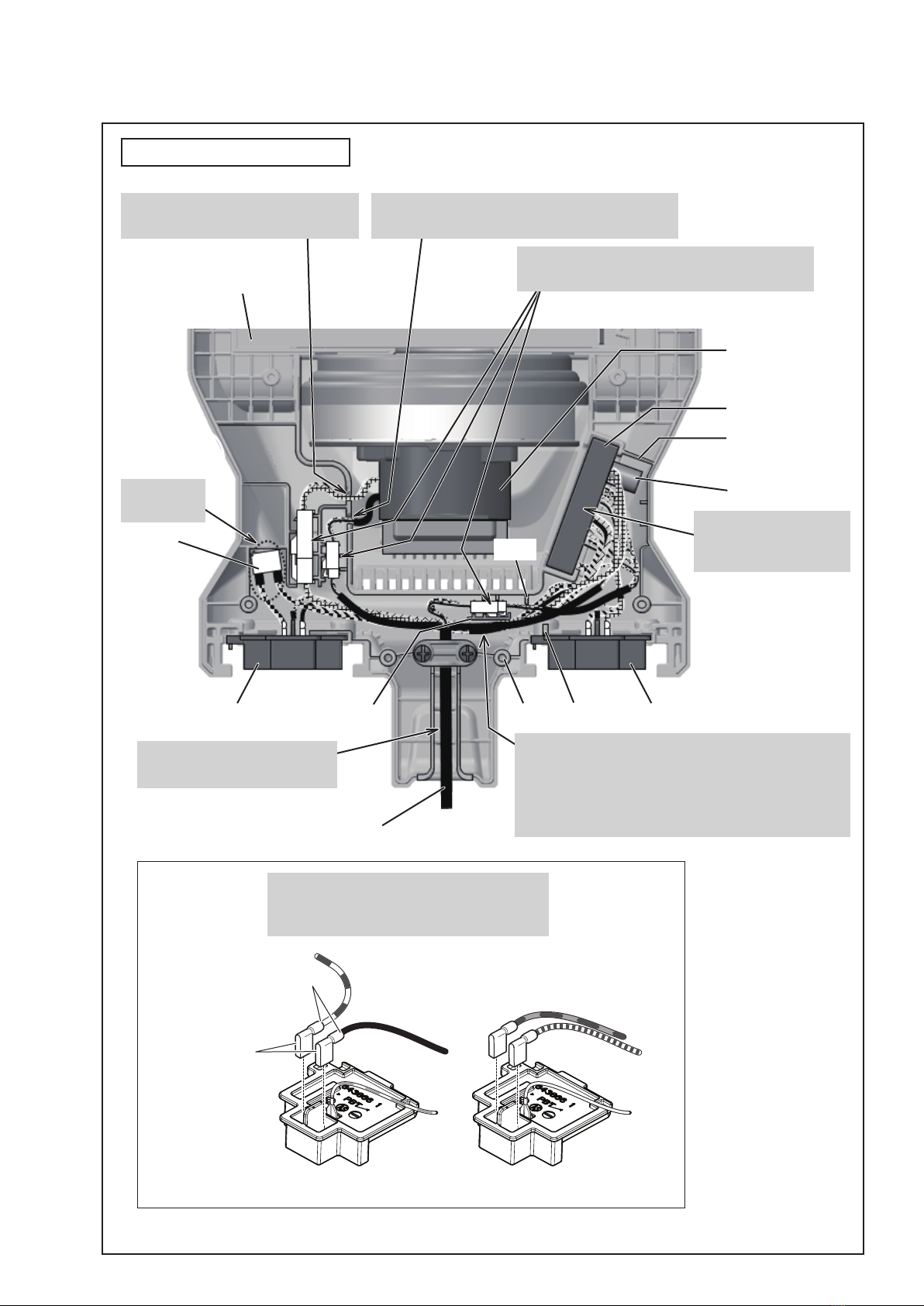

TECHNICAL INFORMATION

1 / 11

OFFICIAL USE

for ASC & Sales Shop