[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

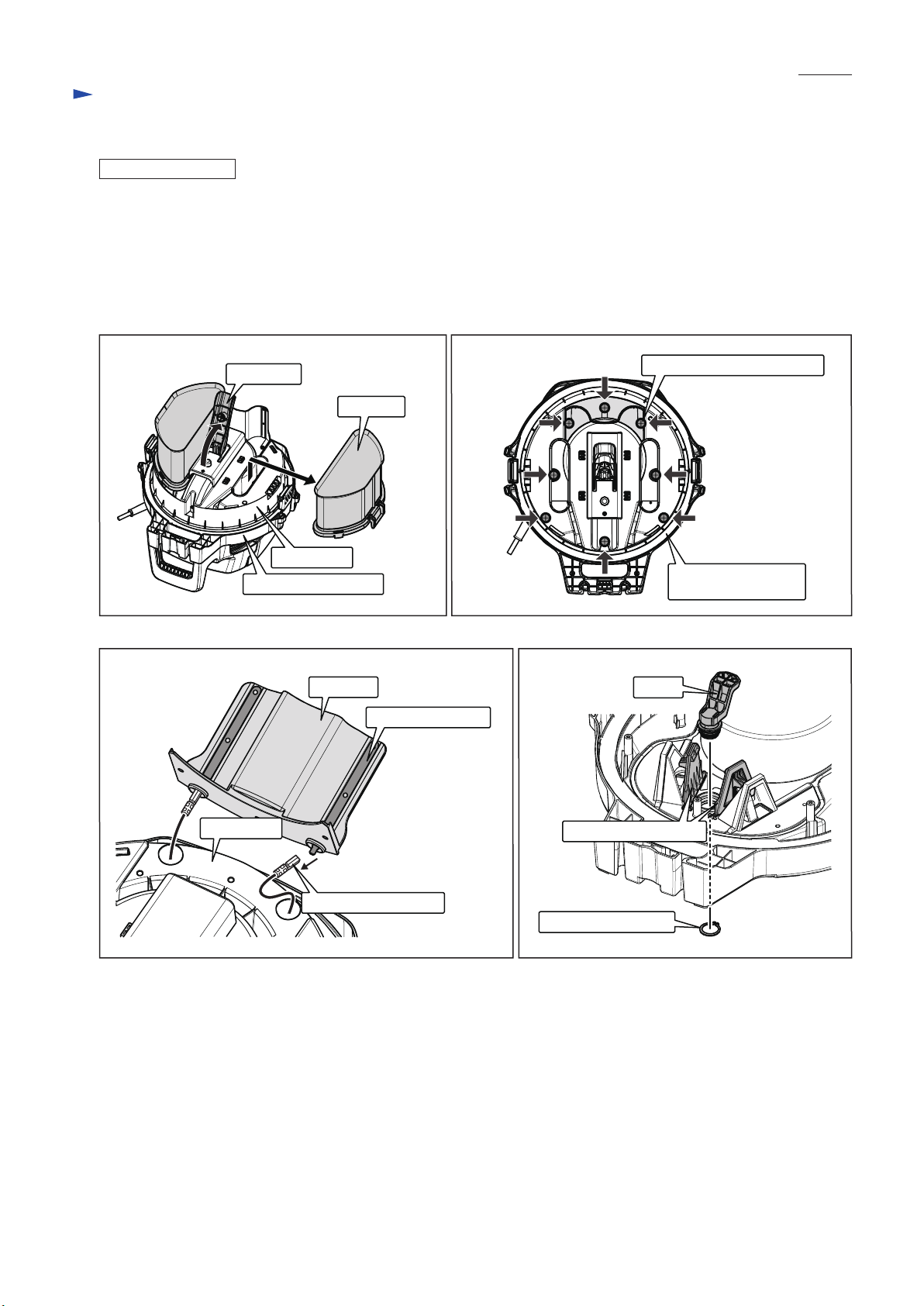

[2] LUBRICANT/ADHESIVE APPLICATION

Pipe ring (for arbor press)1R023

removing Caster 75Bearing extractor1R263

press-fitting Caster 75Type 94 field insert jig1R275

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

CAUTION: When performing startup test of the AC motor with the motor section separated from

the Tank section, be sure to hold the Motor section firmly, or it will move around.

CAUTION: When cleaning dust filtration parts or removing dust from other contaminated parts,

be sure to use Acrylic dust box (Code No. 1R276) so as not to scatter dust.

press-fitting Fan cover onto Return vane

removing dust from the machineAcrylic dust box1R276

V-block1R258 press-fitting Fan cover onto Return vane

Repair

Retaining ring S and R pliers1R291 removing/installing Retaining rings

Torque driver1R344 tightening M5x60 Pan head screws through Endbell and Field into Base

P 2/ 21

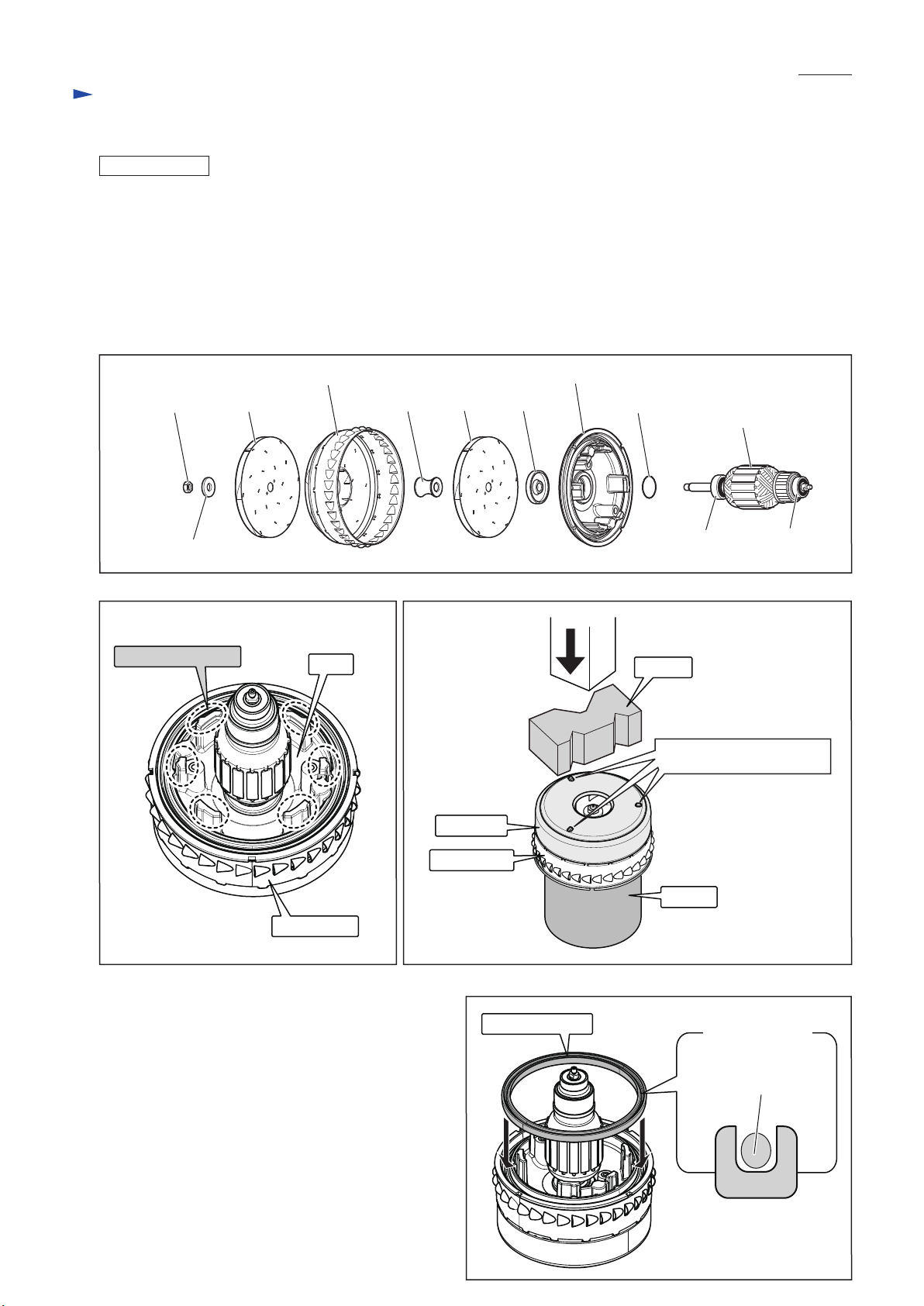

Fig. 1

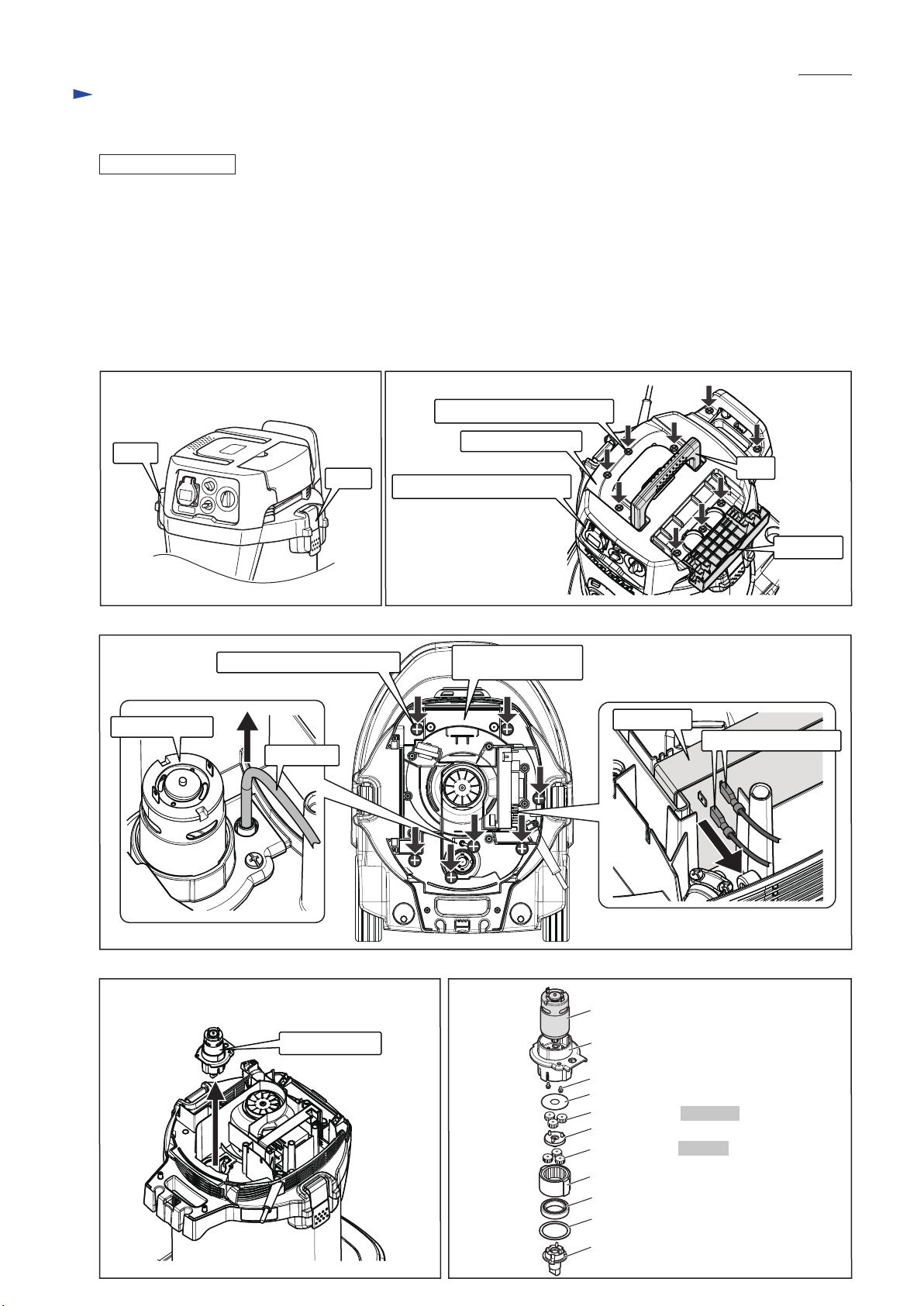

Item

No. Description

O ring 9 whole surface

whole surface

O ring 14

a little

approx. 3g

whole surface

whole surface

Gear case gear chamber where planetary gears engage with Internal gear 42

O ring 9

a little

a little

a little

AmountPortion to lubricate

Apply Makita grease FA No.2 to the following portions designated by black triangle to protect parts and product from

unusual abrasion.. (Fig.1)

Apply ThreeBond 1215 to Rubber ring 120 and Seal ring.

See step (3) of "ASSEMBLING" in [3]-1. Motor section for Rubber ring 120,

and "ASSEMBLING" in [3]-2. Inner cover for Seal ring.

Cam

O ring 20

planetary gear

(Spur gear 15)

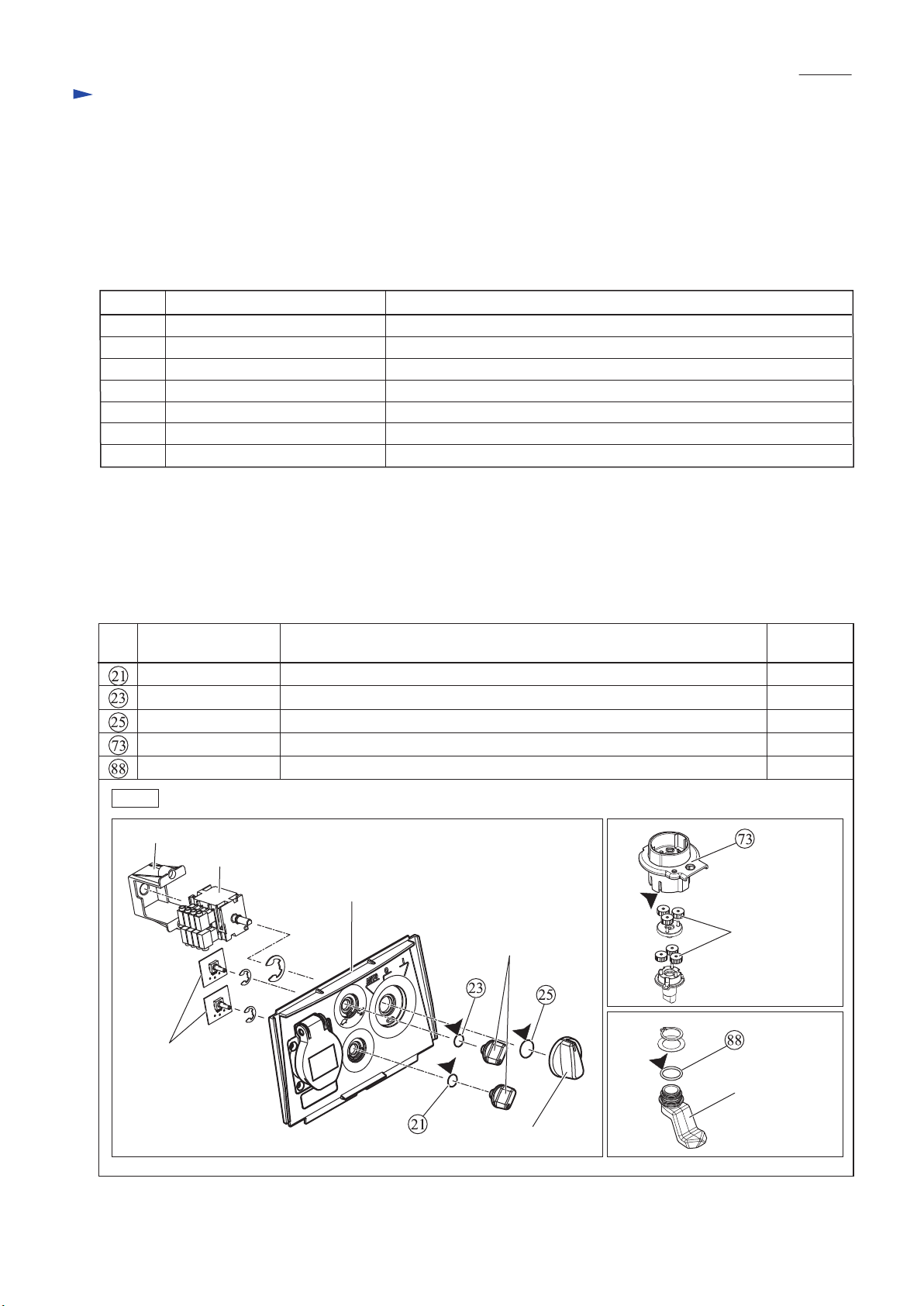

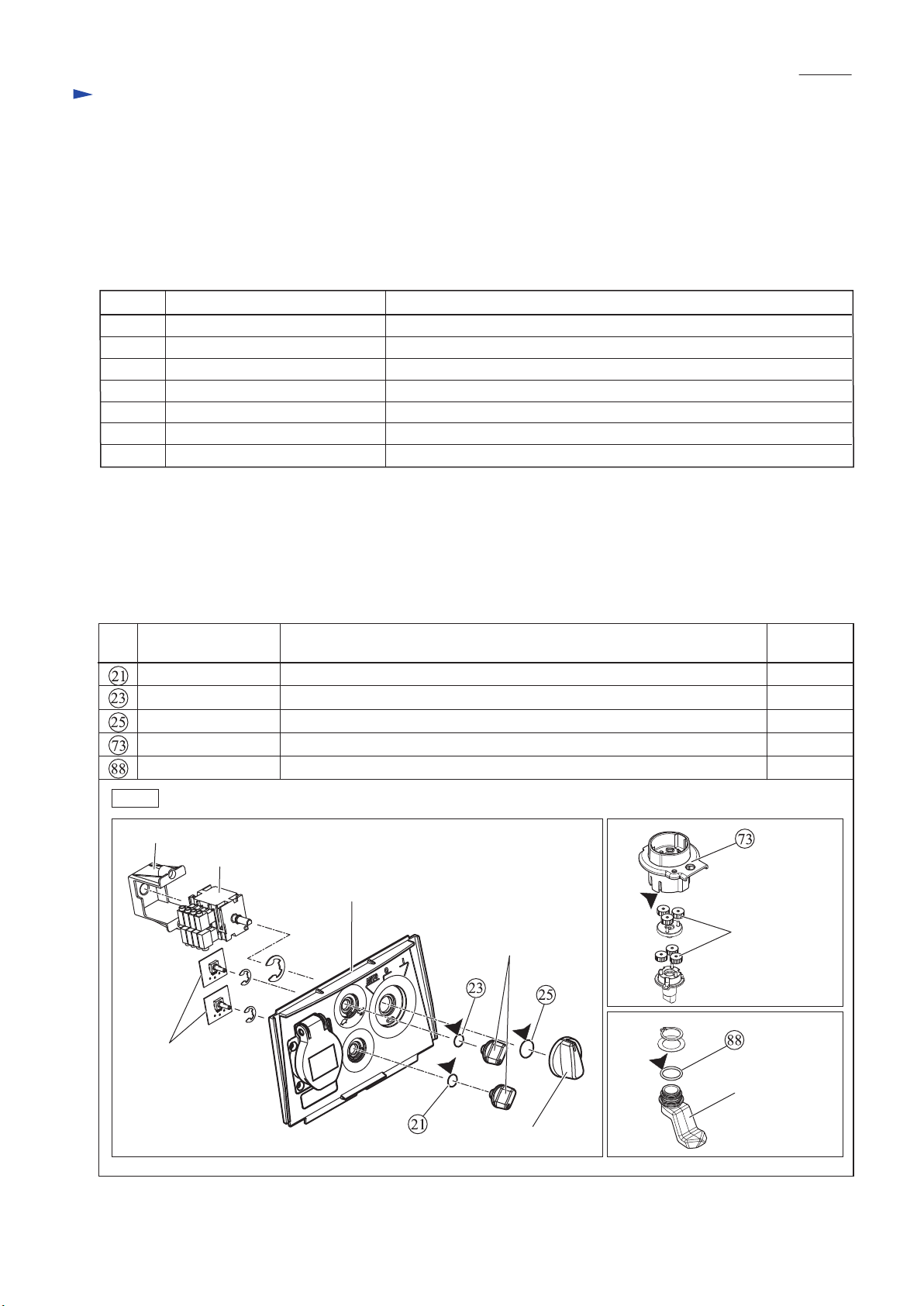

Switch

Switch holder

Sub controller

Switch base E-M complete

Switch lever

Switch dial