Malvern Instruments Spraytec User manual

Spraytec

User Manual

Spraytec

User Manual

MAN0368 Issue 1.0 Nov. 2005

© Malvern Instruments Ltd. 2005

Malvern Instruments makes every effort to ensure that this document is correct. However,

due to Malvern Instruments’ policy of continual product development we are unable to

guarantee the accuracy of this, or any other document after the date of publication. We

therefore disclaim all liability for any changes, errors or omissions after the date of

publication. No reproduction or transmission of any part of this publication is allowed

without the express written permission of Malvern Instruments Ltd.

Head office:

Malvern Instruments Ltd.

Enigma Business Park,

Grovewood Road,

Malvern,

Worcestershire. WR14 1XZ

United Kingdom

Tel + [44] (0)1684-892456

Fax + [44] (0)1684-892789

Windows 2000 and XP are registered trademarks of the Microsoft Corporation.

Spraytec is a registered trademark of Malvern Instruments.

Printed in England

Table of Contents

Part 1 - Operator’s guide

CHAPTER 1 - Introduction to this manual

Introduction 1-1

How to use this manual 1-1

Access to the instrument 1-2

Assumed information 1-3

Where to get help 1-4

CHAPTER 2 - What is the Spraytec?

Introduction 2-1

The Spraytec summarised 2-1

Preparing the spray 2-2

Designing an SOP 2-2

Capturing the scattering pattern 2-3

Calculating the particle size 2-7

Displaying results 2-9

Experiments, records and files 2-11

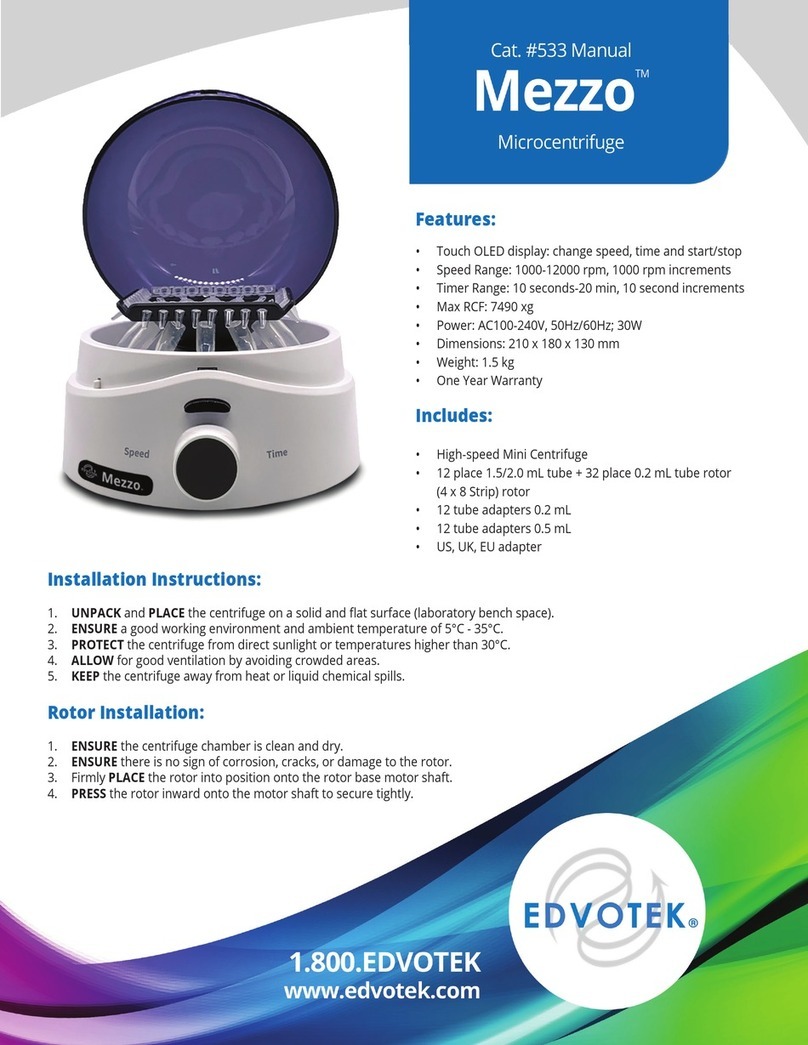

CHAPTER 3 - The Spraytec hardware

Introduction 3-1

Key components 3-1

The Spraytec instrument 3-2

External PSU 3-7

Universal switching box 3-8

Computer and monitor 3-8

Bench shroud 3-9

CHAPTER 4 - The Spraytec software

Introduction 4-1

The main window 4-2

The Measurement file window 4-4

Size History view 4-5

The record views 4-8

The Measurement Manager 4-10

Average PSD window 4-12

CONTENTS

Spraytec Page i

Overlay window 4-13

Menus 4-14

The toolbar 4-18

CHAPTER 5 - Measurement tutorial

Introduction 5-1

Getting started 5-2

Creating an SOP 5-5

Manual measurements 5-29

Measuring the spray 5-30

Results 5-34

CHAPTER 6 - Interpreting the results

Introduction 6-1

Plot and curve types 6-2

Warnings and errors 6-3

Size History view 6-4

Particle Size Distribution view 6-9

Derived Parameters view 6-10

Measurement Parameters view 6-10

Averaging data 6-12

User size bands 6-13

Curve fit 6-15

Using overlays 6-16

Problems with poor data 6-18

Using the Data handling options 6-23

CHAPTER 7 - Using measurement files

Introduction 7-1

Measurement file types 7-1

Using measurement files 7-1

Exporting information 7-2

Printing 7-5

CHAPTER 8 - Basic maintenance

Introduction 8-1

Moving the optical modules 8-1

Changing the lens 8-2

Cleaning the instrument 8-3

Troubleshooting 8-4

CONTENTS Spraytec

Page ii MAN 0368

Part 2 - Supervisor’s guide

CHAPTER 9 - Security

Introduction 9-1

Security principles 9-1

Setting up the Administrator 9-2

Security guidelines 9-3

Setting up user groups 9-4

Setting up individual users 9-5

CHAPTER 10 - Advanced features

Introduction 10-1

Derived parameters 10-2

Triggers 10-5

Alarms 10-8

Spray profiles 10-12

Optical models 10-16

CHAPTER 11 - SOP management

Introduction 11-1

Editing SOPs 11-1

SOP templates 11-2

Deleting an SOP 11-2

Extracting an SOP 11-2

Part 3 - Appendices

APPENDIX A - Health and Safety

General warnings A-1

Laser safety regulations A-2

Spray handling warnings A-4

Moving the system A-5

APPENDIX B - Specification

Specification B-1

Chemical compatibility B-4

CONTENTS

Spraytec Page iii

APPENDIX C - Site requirements

Introduction C-1

Environmental conditions C-1

Space required C-2

Power requirements C-3

Power cords C-3

Additional services C-4

Computer usage C-4

APPENDIX D - Unpacking instructions

APPENDIX E - Installation

Introduction E-1

Moving the instrument E-1

Changing the computer E-3

APPENDIX F - Regulatory statements

CE Declaration of Conformity F-1

FCC Notice (US only) F-2

Canadian Regulatory Information (Canada Only) F-3

VCCI acceptance (Japan only) F-4

Index

CONTENTS Spraytec

Page iv MAN 0368

Part 1 - Operator’s guide

Part 1 - Operator’s guide

Introduction to this manual

Introduction to this manual

CHAPTER 1

Introduction

This manual covers the operation and maintenance of the Spraytec system. In

simple terms the Spraytec measures the size distribution of particles in sprays. It

uses a software package for control, measurement and analysis, presenting the data

according to the user’s needs.

The aims of this manual are to:

.Explain what the Spraytec is, how it works and the parameters it measures.

.Explain in simple terms how the instrument analyses sprays.

.Describe the Spraytec hardware and software components.

.Explain how to use the instrument to make a measurement.

.Explain how to interpret the result data, how to print data and how to ex-

port it to other applications.

.Identify the user maintenance and troubleshooting procedures.

.Provide detailed information on advanced areas like alarms and triggers.

.Show supervisors how to configure security.

How to use this manual

Users must read the Health and Safety information in Appendix A before

operating the instrument. The information given in this appendix applies to the

Spraytec instrument itself, as well as accessories used with it.

We recommend reading this manual fully before starting the first measurement.

Those who are more familiar with laser diffraction as applied to sprays can jump

straight to Chapter 5 which is a practical tutorial on making measurements.

The manual is divided into the following three sections.

Part 1 - Operator’s guide

The Operator’s guide contains all the information required by an operator using

the Spraytec. Topics covered are:

.What the Spraytec does.

.The Spraytec hardware and software components.

.A tutorial – describes how to create three types of Standard Operating

Procedure (SOP) and make a measurement.

.How to interpret the results.

.How to print results and export information for use elsewhere.

.Basic maintenance and troubleshooting procedures.

CHAPTER 1

Spraytec Page 1.1

Part 2 - Supervisor’s guide

The Supervisor’s guide concentrates on administration and the more advanced

Spraytec features. Topics covered are:

.Security – explains how to set up administrators, users and user groups.

.Advanced features – describes triggers, alarms, spray profiles, etc. in detail.

.SOP management – describes how to edit and delete SOPs and also how to

set up SOP templates.

The supervisor should also read Part 1 - Operator’s guide.

Part 3- Appendices

Appendix A contains essential Health and Safety information which all users must

read. Appendices B and C give the specification and site requirements. The other

appendices contain supplementary information not necessary for the general

operation of the system.

Access to the instrument

This manual refers to the various people who will have access to the instrument,

as follows.

Malvern personnel

Malvern personnel (service engineers, representatives, etc.) have full access to the

instrument and are the only people authorised to perform all service procedures

that may require the removal of the covers.

#

Warning!

Supervisor

The supervisor is the person responsible for the management and safety of the

instrument and its operation. The supervisor is responsible for training the

operators. The supervisor can perform all user maintenance routines identified in

Chapter 8.

CHAPTER 1 Spraytec

Page 1.2 MAN 0368

Removal of the covers by unauthorised personnel will invalidate the

warranty of the instrument.

Operator

An operator is a person trained in the use of the system. The operator can

perform all user maintenance routines identified in Chapter 8.

#

Warning!

Assumed information

Naming convention

The Spraytec is referred to either in full as ‘the Spraytec’ or as ‘the instrument’.

The combination of the Spraytec instrument, the computer and the Spraytec

software is referred to as ‘the system’.

Menu commands

Menu commands in the Spraytec software are always shown in bold text and

shown in the form:

main menu-menu item-submenu item.

As an example, the command Tools-Options-Serial Port refers to selecting the

Serial Port option of the Options command in the Tools menu.

CHAPTER 1

Spraytec Page 1.3

Under no circumstances should a supervisor or operator remove the

main cover of the instrument. Failure to follow these guidelines could

result in exposure to hazardous voltages.

Where to get help

Manual and online help

The primary sources of information on the Spraytec system are this manual and

the software’s online help. This manual gives an overview of the system as a

whole, while the online help gives detailed information on the Spraytec software.

Each dialogue in the Spraytec software has a Help button giving information on

its use.

Accessories manual

The Spraytec Accessories User Manual provides details on the use, functions

and maintenance of the following options/accessories:

.Spraytec NSS – the actuator support system.

.Air Purge – used to keep the instrument windows clear of spray.

.Extractor – used to draw spray through the measurement zone.

As further accessories become available, the manual will be expanded to cover

these.

Help desk

All queries regarding the system should initially be directed to the local Malvern

representative. Please quote the following information:

.The model and serial number of the instrument (located on the back of the

Receiver module). This is also available from the software when an instru-

ment is connected.

.The Spraytec software version (to find this, select Help-About in the soft-

ware).

Contact the United Kingdom help desk if the local Malvern representative is not

available. Its direct line is +44 (0) 1684 891800.

'Note .This help line is primarily English speaking.

CHAPTER 1 Spraytec

Page 1.4 MAN 0368

Remote support

Malvern Instruments offers a remote support service, delivered by an Internet

connection. Benefits include fast and efficient fault diagnosis, reducing downtime

and costs.

Online user training is also available, plus software updates. A high speed Internet

connection is recommended for making use of this facility.

Malvern Website - www.Malvern.co.uk

The Malvern website offers a comprehensive range of particle characterisation

resources for use by customers 24 hours a day, seven days a week.

Resources include software downloads, frequently asked questions, a knowledge

base and application notes, plus information on other particle characterisation

solutions that Malvern can provide.

CHAPTER 1

Spraytec Page 1.5

CHAPTER 1 Spraytec

Page 1.6 MAN 0368

What is the Spraytec?

What is the Spraytec?

CHAPTER 2

Introduction

This chapter describes the full process of making a measurement, explaining at

each stage how the Spraytec works. It begins with a summary of what the Spraytec

does, then covers the following:

.Preparing the spray and the instrument.

.Designing a Standard Operating Procedure (SOP).

.Capturing the scattering pattern – the principles of Spraytec operation.

.Calculating the particle size.

.Displaying results – the importance of volume-based results and how pa-

rameters are derived.

.General issues – experiments, records and the use of measurement files.

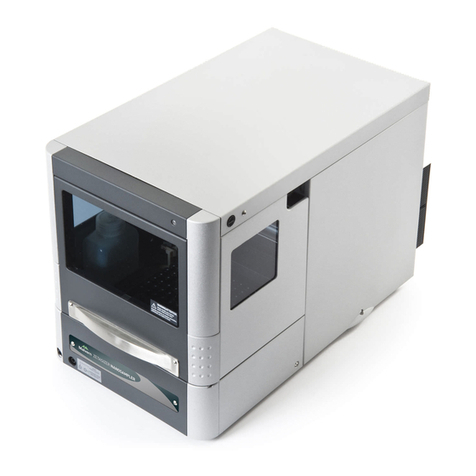

The Spraytec summarised

The Spraytec instrument measures the size of particles in a spray. Specifically, it

measures the distribution of different sizes within a spray. The measurement

process involves the following steps:

.A spray is prepared and delivered using an appropriate spray delivery device

or accessory.

.The spray is delivered between the two functional modules of the instru-

ment, the Transmitter and Receiver modules.

.The Transmitter uses a He-Ne (Helium-Neon) laser to produce a laser

beam that passes through the spray delivered to the measurement zone.

.Detecting optics in the Receiver module detect the light diffraction pattern

produced by the spray, converting the light detected into electrical signals.

The signals are processed by analogue and digital electronics boards, and

passed to the analysis software.

The light diffraction pattern is analysed using an appropriate scattering

model to calculate the spray size distribution.

.The software displays the results in a number of forms, including histo-

grams, result-under plot and result-over plot, etc.

.The user further processes the data as required, re-analysing records, aver-

aging records, comparing sprays using overlays, etc.

.Saved data is exported as required for use and further analysis elsewhere.

The use of Standard Operating Procedures (SOPs) ensures that results are as

objective and reproducible as possible.

CHAPTER 2

Spraytec Page 2.1

Preparing the spray

This involves:

.Priming the device, in some instances.

.Positioning the spray, taking into account the distance to the measurement

zone, the working range and the risk of contaminating the optics.

.Considering whether extraction is needed to draw the spray through the

measurement zone.

.For sprays like nasal sprays, setting actuation parameters to control the

atomisation process.

.Taking account of ambient conditions, for example direct sunlight.

Designing an SOP

There are two ways to make a measurement; manually or using a Standard

Operating Procedure (SOP). An SOP is like a template that defines a set of

measurement parameters and settings. Advantages of using SOPs are:

.It ensures that measurements made on similar sprays are made in a consis-

tent way, essential in quality control environments. SOPs can be created or

modified as required.

.SOPs are ideal for measuring the same spray in slightly different ways. In-

stead of setting up sets of largely identical parameters each time, the user

copies an existing SOP and just changes the required parameters. This re-

duces the risk of making errors in the settings.

.An SOP can be created centrally and then distributed to all Spraytec users

within an organisation. Anyone can create an SOP but typically it is the re-

sponsibility of the system administrator.

Default SOP templates are provided for continuous sprays, rapid mode

measurements and nasal sprays. Initially it may be best to use one of these, then

refine it later as experience grows. The user can design more templates to extend

the set of defaults.

The software can be used to create an SOP without an instrument connected.

The software can be installed on a remote computer and SOPs created and edited

before they are tested on an instrument.

CHAPTER 2 Spraytec

Page 2.2 MAN 0368

Table of contents

Other Malvern Instruments Laboratory Equipment manuals

Malvern Instruments

Malvern Instruments Zetasizer uV User manual

Malvern Instruments

Malvern Instruments ZETASIZER User guide

Malvern Instruments

Malvern Instruments Zetasizer Series User manual

Malvern Instruments

Malvern Instruments Zetasizer uV User manual

Malvern Instruments

Malvern Instruments Mastersizer X User manual

Malvern Instruments

Malvern Instruments DEG0003 User manual

Malvern Instruments

Malvern Instruments Zetasizer Nano User manual