Contents

1 Legal Information.........................................................................................................4

2 About this Document..................................................................................................5

2.1 Objective and Target Group..............................................................................5

2.2 Other Applicable Documents............................................................................5

2.3 Explanation of Symbols....................................................................................5

2.3.1 Typographic Conventions................................................................. 5

2.3.2 Symbols Used.................................................................................... 6

2.4 Figures................................................................................................................6

2.5 Downloading Manuals...................................................................................... 6

3 Safety............................................................................................................................8

3.1 Intended Use......................................................................................................8

3.2 General Safety Instructions.............................................................................. 8

3.3 Organizational Measures.................................................................................. 8

3.3.1 User Manual....................................................................................... 8

3.3.2 General Personnel Qualification.......................................................8

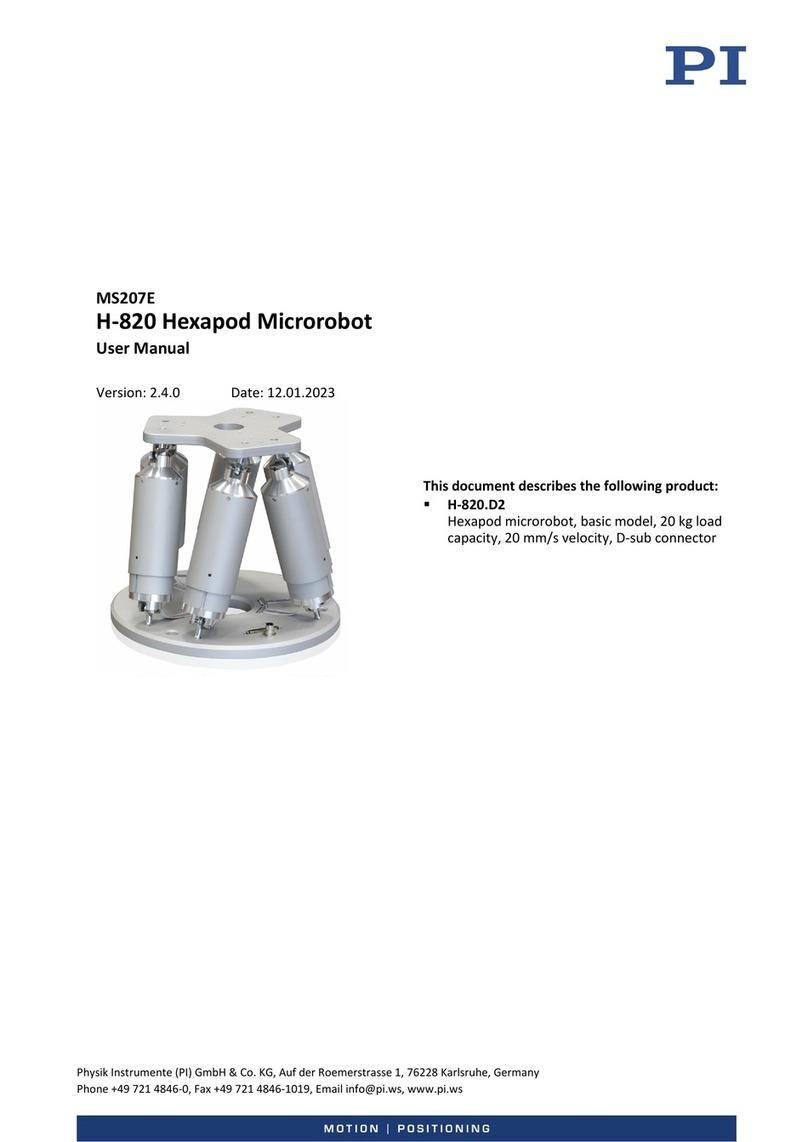

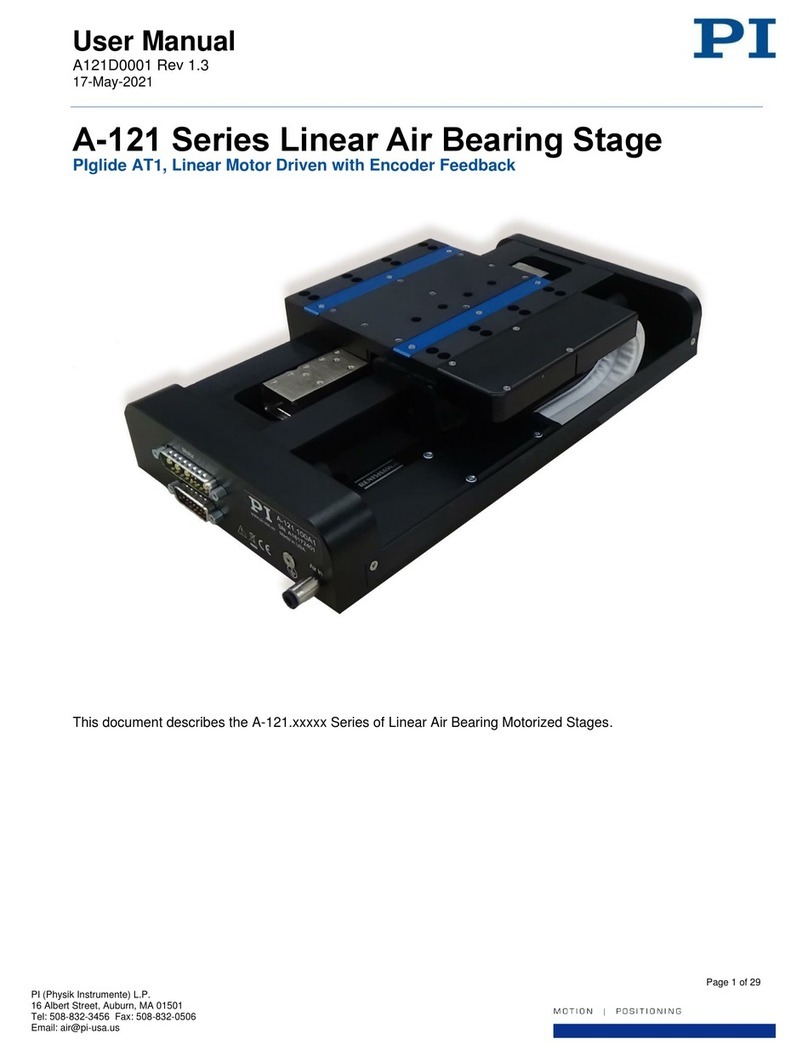

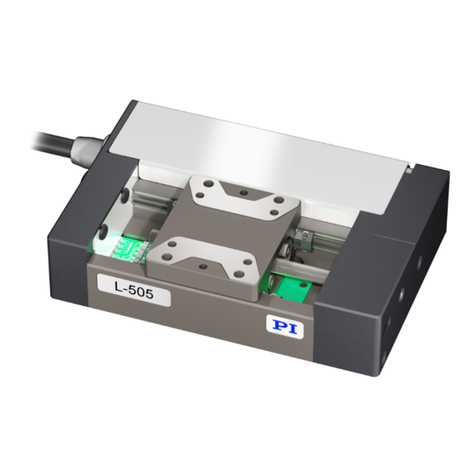

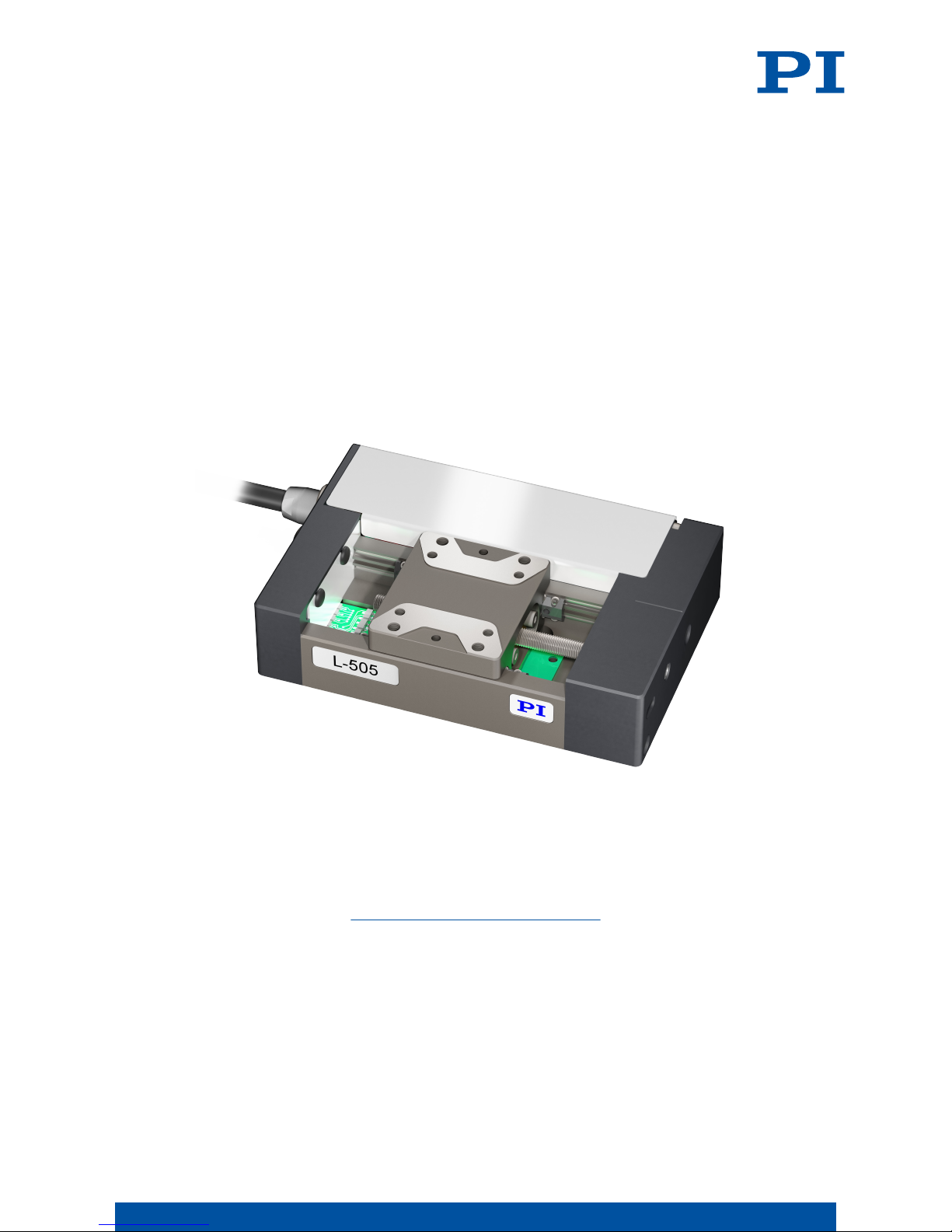

4 Product Description..................................................................................................... 9

4.1 Product Labeling................................................................................................9

4.1.1 Type Plate........................................................................................... 9

4.2 Scope of Delivery.............................................................................................10

4.3 Overview.......................................................................................................... 10

4.3.1 Base Body......................................................................................... 10

4.3.2 Drive Connection..............................................................................11

4.4 Suitable Electronics......................................................................................... 11

4.5 Accessories.......................................................................................................11

5 Unpacking.................................................................................................................. 12

6 Installation................................................................................................................. 13

6.1 Mounting the L-505.02A212F.......................................................................... 13

6.2 Connecting the L-505.02A212F to the Protective Earth Conductor.............. 14

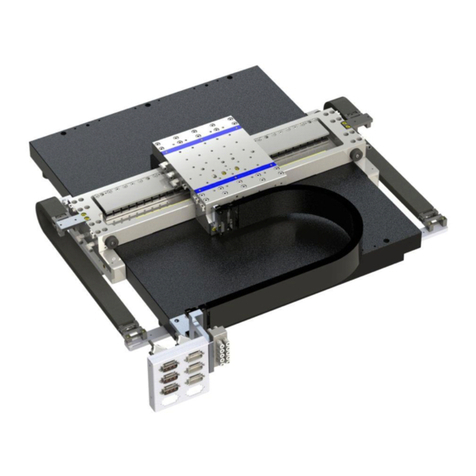

6.3 Setting Up a Multi-Axis System..................................................................... 15

6.4 Building a Vertical Multi-Axis System............................................................17

6.5 Mounting the Load onto the L-505.02A212F..................................................20

6.6 Connecting the L-505.02A212F........................................................................21

7 Startup / Operation................................................................................................... 23

7.1 Starting and operating the L-505.02A212F.....................................................23

8 Maintenance...............................................................................................................25

8.1 Maintenance Run.............................................................................................25

8.2 Relubricating.................................................................................................... 25

8.3 Moving the Motion Platform by Hand........................................................... 26

8.4 Cleaning............................................................................................................26

CONTENTS L505M0020EN ‒ 10/22/2018

2MOTION | POSITIONING