www.mc-techgroup.com CSS-M | 1.02.01 3

Contents

1General information....................................................................................................................... 5

2Declaration of conformity ............................................................................................................. 5

3Safety instructions......................................................................................................................... 6

3.1Intended use ............................................................................................................................. 6

4Warranty ......................................................................................................................................... 7

5Used terms and signal indications............................................................................................... 7

6Introduction .................................................................................................................................... 9

7Application ..................................................................................................................................... 9

8Technical Data.............................................................................................................................. 10

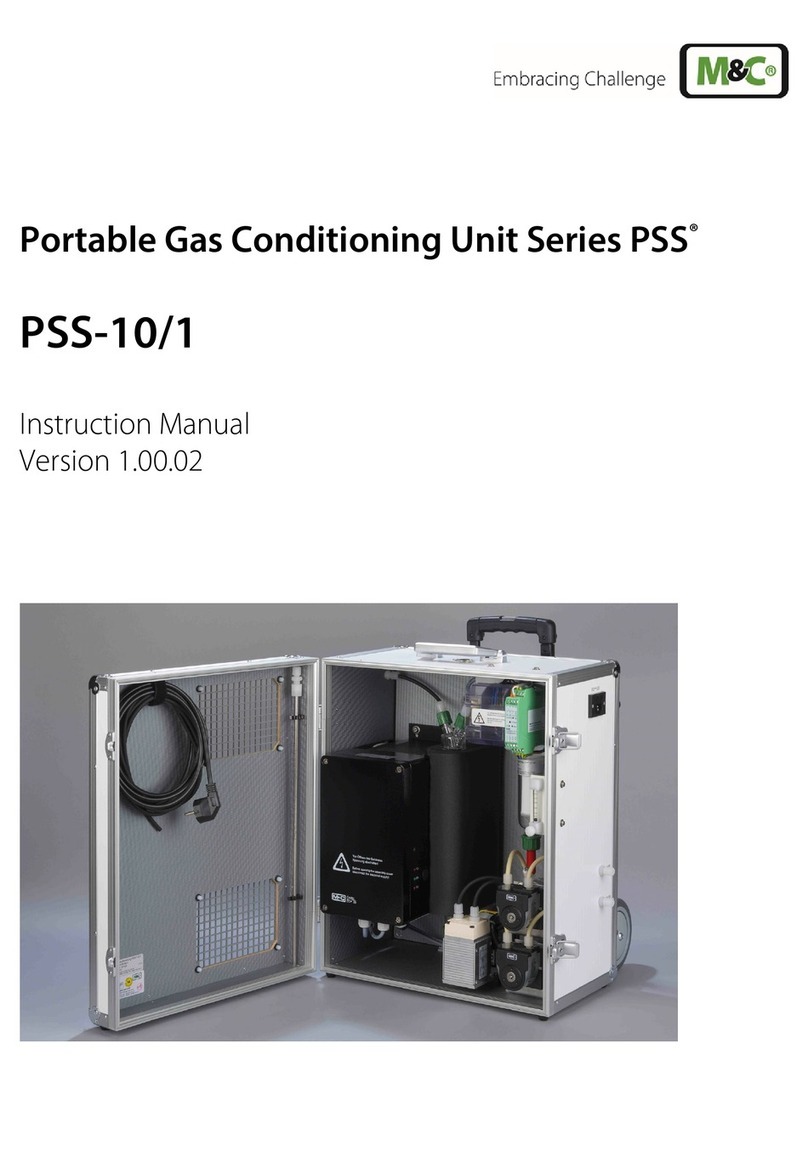

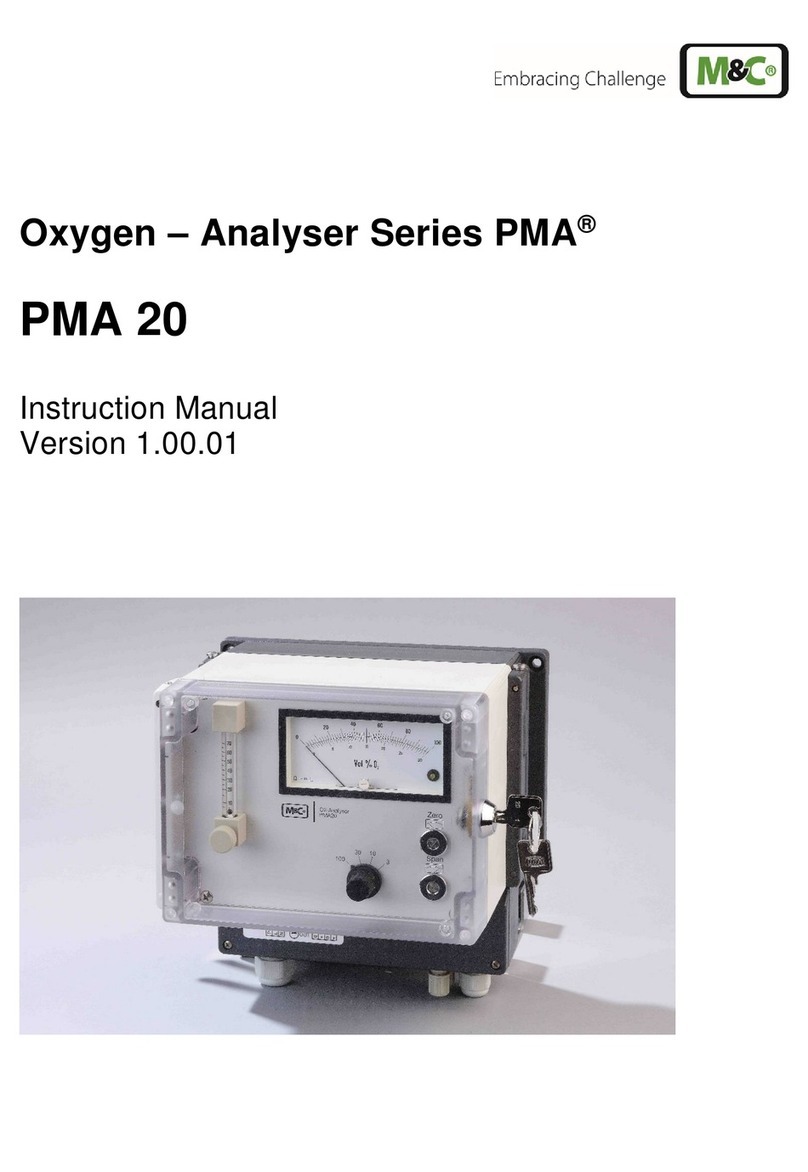

9Description ................................................................................................................................... 11

10Receipt of marchendise and storage .....................................................................................12

11Installation instructions.......................................................................................................... 12

12Supply connections ................................................................................................................. 13

12.1Hose connections ................................................................................................................... 13

12.2Electrical connections ............................................................................................................. 14

13Starting...................................................................................................................................... 15

13.1Cooler regulation .................................................................................................................... 16

13.2New pump switch since 06/2007 ............................................................................................ 16

14Closing down............................................................................................................................ 18

15Maintenance..............................................................................................................................18

15.1Replacement of the filter element and the O-Ring.................................................................. 19

15.2Dismounting the sample gas pump for examination or maintenance ..................................... 20

15.3Maintenance of the integrated peristaltic pump type SR25.2 ................................................. 20

15.3.1Mounting instructions for peristaltic pump ....................................................................... 21

15.3.2Changing the pump tubing .............................................................................................. 22

15.3.3Changing contact pulleys and springs............................................................................. 23

15.3.4Reassembly of the driver................................................................................................. 25

15.3.5Cleaning the pump head ................................................................................................. 25

15.3.6Repair information for integrated peristaltic pump type SR25.2 ...................................... 25

16Operating of the built-in electronic temperature controller ................................................. 26

16.1Temperature controller version until march 2022 ................................................................... 26

16.1.1Changing the set value.................................................................................................... 26

16.2Temperature controller version starting april 2022 .................................................................26

16.2.1Changing the set value.................................................................................................... 27

17Trouble shooting ...................................................................................................................... 27

18Proper disposal of the device .................................................................................................28

19Spare part list ........................................................................................................................... 29

20Appendix ................................................................................................................................... 30