www.mc-techgroup.com PSS-10 | 1.00.02 3

Content

1General information........................................................................................................................................ 4

2Declaration of conformity.............................................................................................................................. 4

3Safety instructions........................................................................................................................................... 5

4Warranty ............................................................................................................................................................ 5

5Used terms and signal indications ............................................................................................................... 6

6Introduction...................................................................................................................................................... 8

7Application........................................................................................................................................................ 8

8Technical data .................................................................................................................................................. 9

9Description...................................................................................................................................................... 10

10 Receipt of goods and storage ..................................................................................................................... 12

11 Installation instructions................................................................................................................................ 13

12 Supply connections....................................................................................................................................... 14

12.1 Tube connections.........................................................................................................................................................................................14

12.2 Electrical connections ................................................................................................................................................................................16

13 Commisioning ................................................................................................................................................ 17

14 Closing down .................................................................................................................................................. 18

15 Maintenance ................................................................................................................................................... 19

16 Trouble shooting ........................................................................................................................................... 20

17 Proper disposal of the device...................................................................................................................... 21

18 Spare parts list................................................................................................................................................ 22

19 Appendix ......................................................................................................................................................... 23

List of Figures

Figure 1 Flow sheet.......................................................................................................................................................................................................8

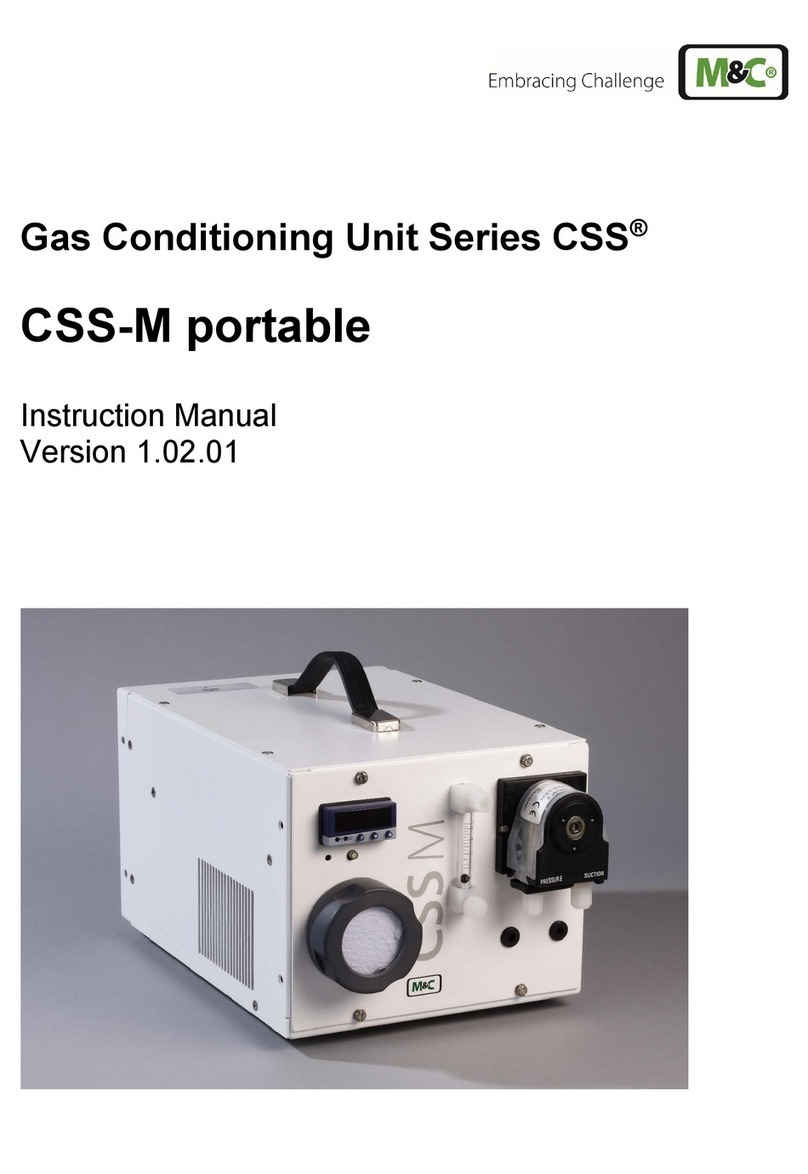

Figure 2 Design of the portable conditioning and sampling system PSS-10/1...................................................................10

Figure 3 Medium connections............................................................................................................................................................................14

Figure 4 Connecting heated sample line with special adapter (option)..................................................................................24

Figure 5 Circuit diagram PSS-10/1, shown here: circuit diagram for 230 V.............................................................................25