– 6 –

ASSEMBLY

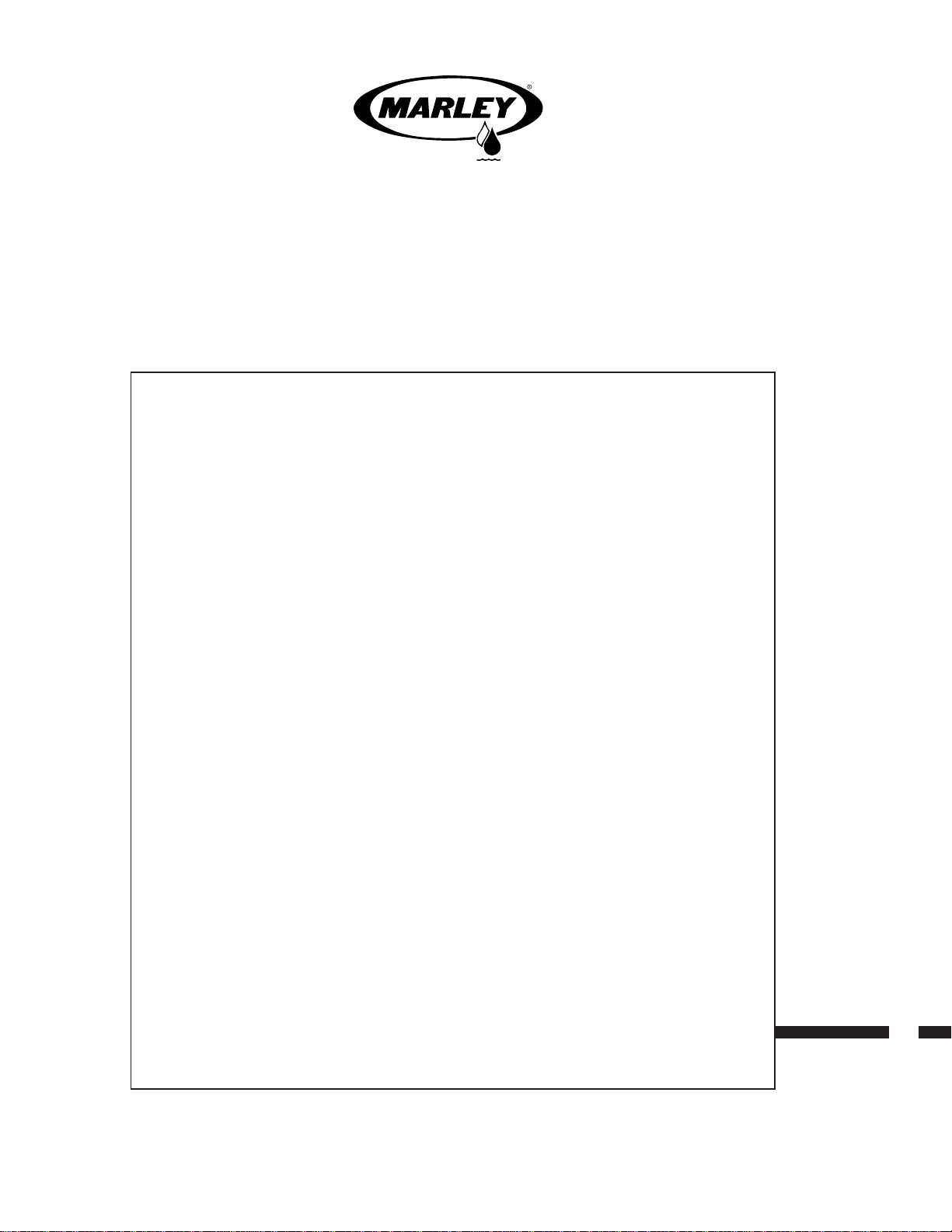

Beforeassemblinganewpiniongearinthepinioncage,check

matchnumberson pinion gear and spiral bevelringgeartobe

certain that they are a matched set. Gears are lapped in

matched sets at the factory and should not be separated.

Numbers are etched on both the pinion and ring gear as

illustrated in Fig. 1, page 2.

All parts that are to be reused should be thoroughly cleaned

with Kerosene before being reinstalled. Do not remove new

bearingsfromcartonuntilreadytouse.Washallbearings(new

or old) with Kerosene. Do not spin-dry bearings. Take each

bearingsetandrollthecupontheconetonoteanyroughness.

Replace bearing if necessary. If bearings cannot be installed

immediatelyafterwashing,lubricateandcoverthemtoprotect

against dust, moisture, etc.

If a press is not available to install bearing cones, they can be

heated as long as the temperature does not exceed 275°-

300°F. If the bearings get hotter than this, they will begin to

draw and soften. Bearings can be heated with infrared lamps

or with oil baths. If an oil bath is used, the bearing should be

supported an inch or so above the pan to prevent local

overheating.

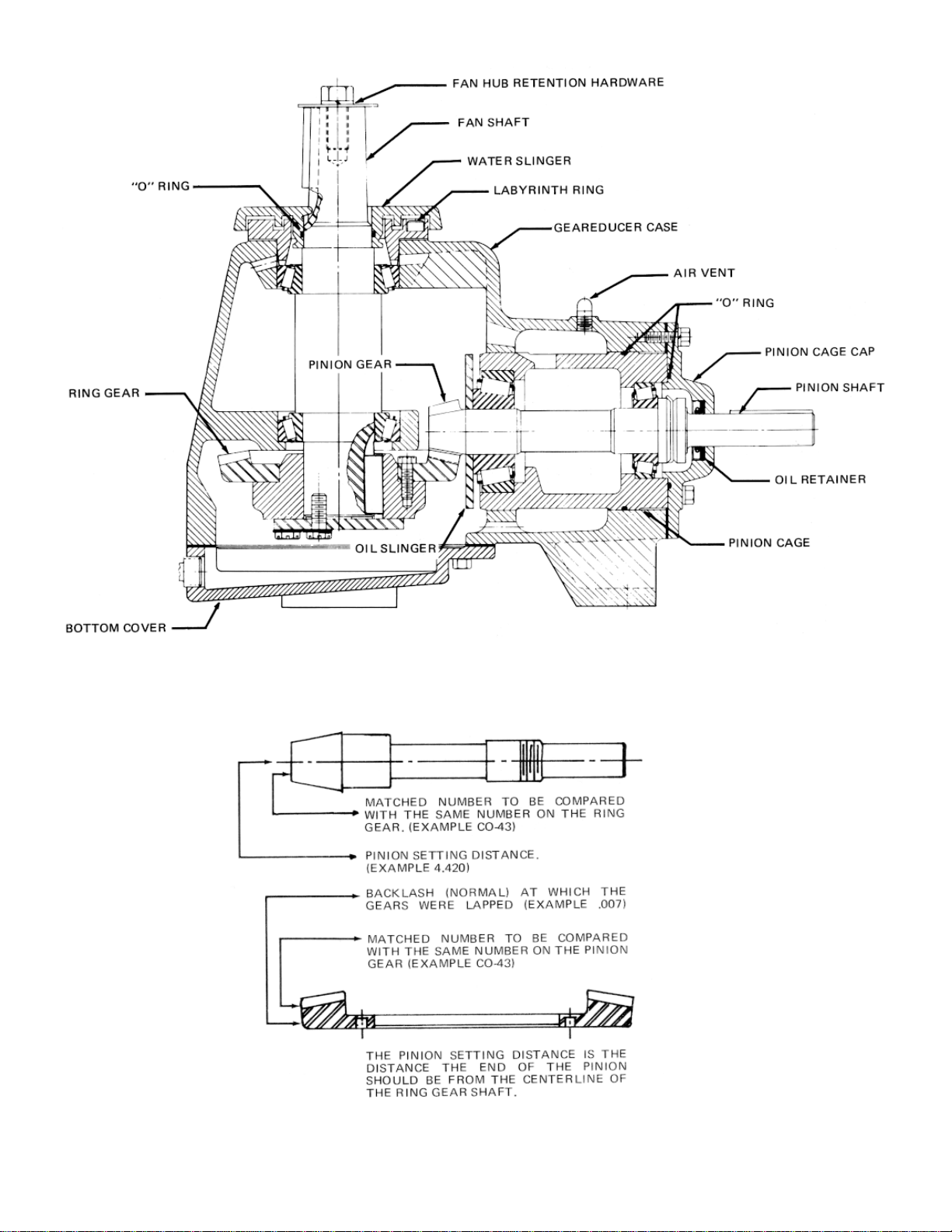

PINION CAGE SUB-ASSEMBLY

1. Place oil slinger (Item 2.11) on pinion shaft (Item 2.9).

2. Press head bearing cone (Item 2.12) on pinion shaft

making sure oil slinger and bearing are against gear.

3. Pressbearingcups(Items2.13and2.14)intopinioncage

(Item 2.4).

4. Lowerpinioncageonpinionshaft,untilheadbearingcone

and cup mate.

5. Press tail bearing cone (Item 2.10) on pinion shaft until it

mates with its bearing cup.

6. Install locknuts (Item 2.7) and lockwasher (Item 2.8).

Tighten nuts on bearing cone until 5 to 15 inch pounds of

bearing preload is obtained. Bearing preload is the resis-

tancein the bearingstoshaft rotation measuredinin./lbs.

torque required to rotate the shaft at uniform velocity.

Preload is necessary to insure the stability of the gear

engagement. Crimp the lockwasher to hold the two nuts

in place.

7. Install “O” ring (Item 2.6) in groove.

8. Installoilretainer(Item2.15)inpinioncagecap(Item2.2).

This seal is to prevent oil leaking out of the Geareducer;

therefore, the sealing lip must point inward. Clean oil

retainer seat in cap and press retainer in place. Use a

short piece of pipe with outside diameter .010 to .020 in.

Iess than the retainer outside diameter. Do not apply

hammer blows or uneven pressure directly to seal sur-

face. Be careful not to tip retainer while installing it.

Provide a sleeve to protect the seal lip as it passes over

the shaft keyway. Shim stock .010 to .015 inch thick can

be used for this sleeve as long as the lapping edge is

smoothed off and the seal is turned with the lap in the

sleeve rather than against it. A small amount of light

grease can be used to lubricate the sealing lip.

9. Position “O” ring (Item 2.5) and push cap (Item 2.2) (with

seal and sleeve) in place on shaft. Attach cap to pinion

cage and slide sleeve from cap.

10. Record the pinion setting distance that is etched on the

pinion gear.

INSTALLATION OF FAN SHAFT

1. Press bottom bearing cup (Item 15) in case.

2. Press bearing cones (Item 13 and 14) on fan shaft (Item

10).

3. Lower fan shaft into case until bearing cone mates with

bearlng cup.

4. Press top bearing cup (Item 11 ) into case.

5. Install labyrinth ring (Item 8) and adjust cap screws (Item

16) until a bearing preload of 5 to 15 inch pounds is

obtained.Measurethegapbetweenthelabyrinthringand

thecase.Makeashimpack(Item9)equaltothethickness

of this gap. Remove ring and install shim pack. Reinstall

labyrinth ring and check bearing preload. If necessary,

adjust shim gap to obtain the proper bearing preload .

INSTALLATION OF RING GEAR HUB

1. Attach ring gear (Item 12) to hub (Item 6). (Use 30 to 35

foot pounds torque on place bolts.)

2. Press ring gear hub on the fan shaft.

CAUTION: Block the end of the fan shaft while pressing

hub on shaft. Do not press against top bearing.

The

tapped hole (5/8-11NC x 1.00 deep) in the end of the fan

shaft may be used to pull the hub on. (If the tapped hole

is used, check around the hole after the hub is on to be

surethereare no raisededgesthatwouldkeep the shims

(Item 5.1 ) from seating properly against the shaft.) Stop

the bottom edge of the hub approximately .100 from the

end of the shaft.

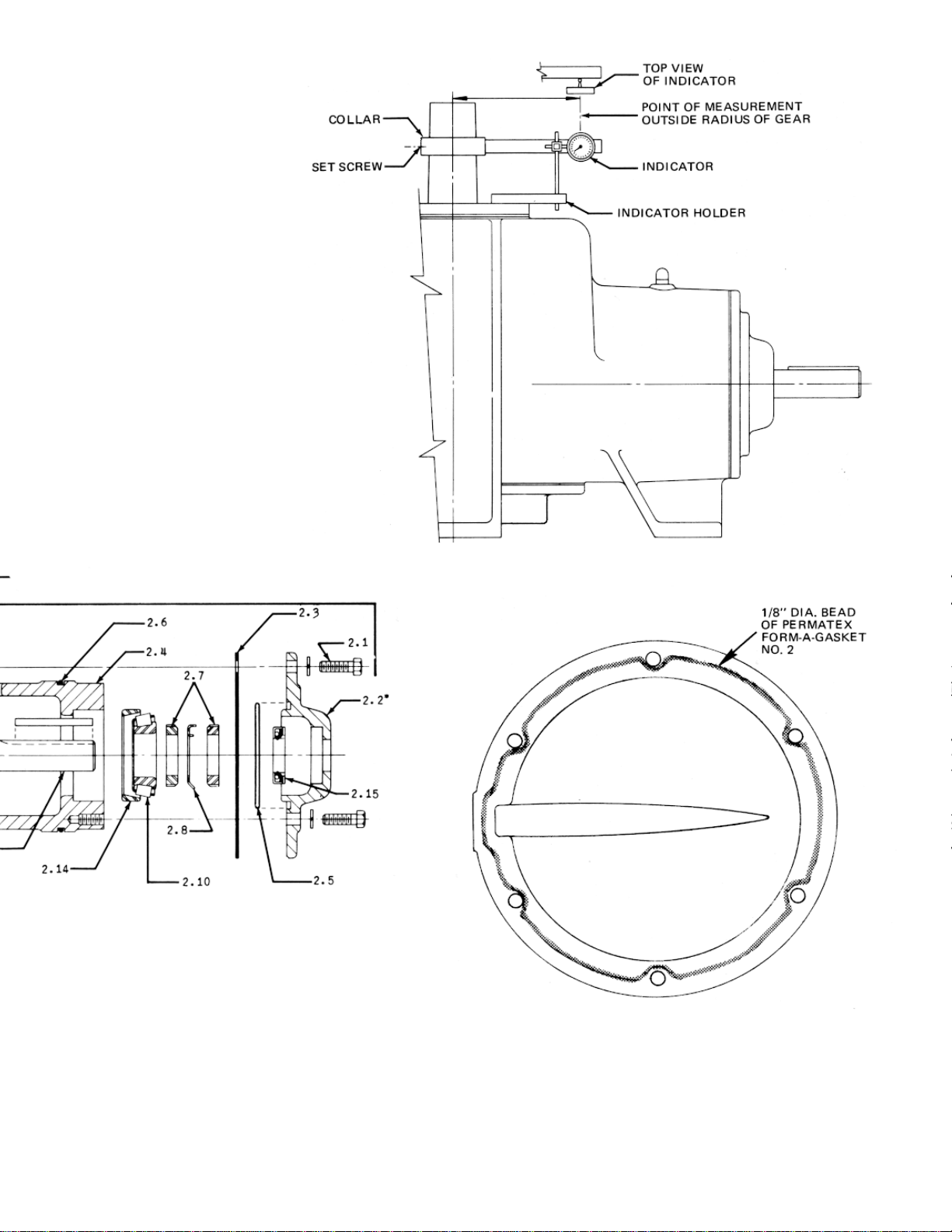

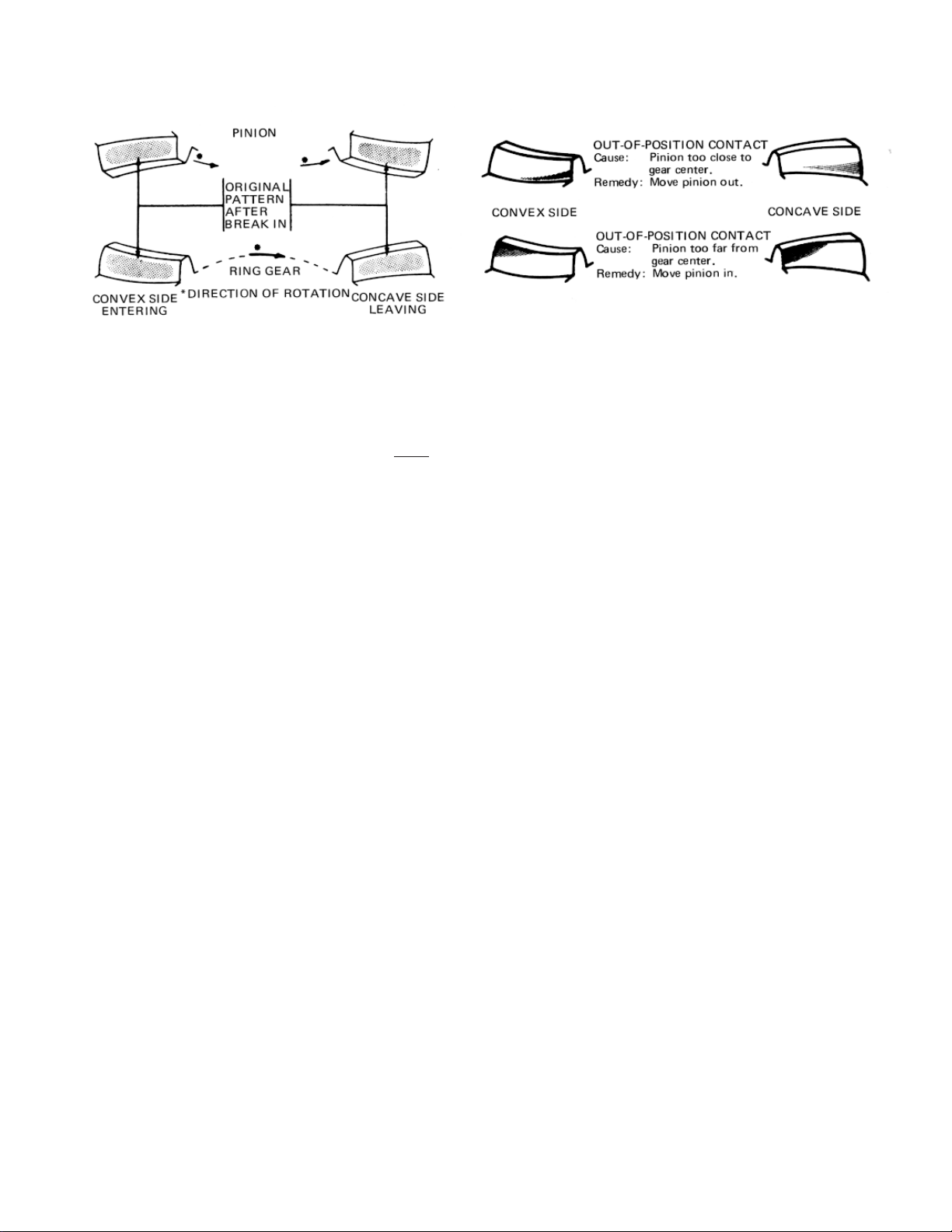

INSTALLATION OF PINION CAGE

1. The “X” marked pinion and gear teeth should be clearly

identifiedwith chalk or other markings which canbe seen

from the inspection opening or the bottom of the case.

2. Findthedifference between the pinionsettingdistanceof

the old gear and the new pinion gear and adjust the old

shimpack(Item2.3)ormakeanewshimpacktocompen-

sate for the different setting distances.