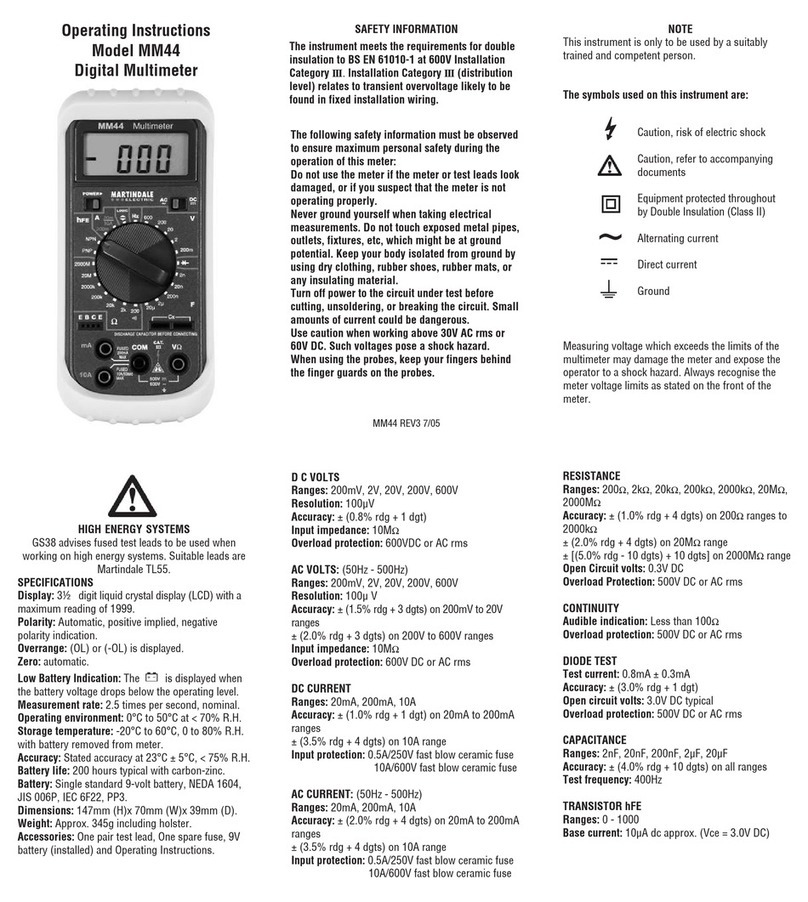

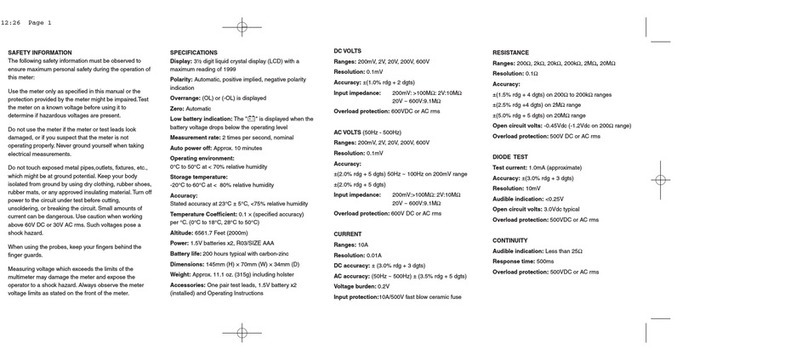

2. TECHNICAL SPECIFICATION

Display: 3.5 digit liquid crystal (LCD), maximum reading 3200 with floating

decimal point. Updates at 2.5 times per second.

Polarity: Automatic, implied for positive values, "-" to show negative

readings.

Overrange: OL or -OL is displayed.

Zero: Automatic.

Low battery indication: A " " symbol appears when the voltage drops

below that required for correct operation.

Auto Power Off: After approx. 10 minutes.

Operating: 0 to 50°C @ < 70% relative humidity (RH).

Storage: -20 to 60°C, 0 to 80% RH (battery must be removed).

Temperature coefficient: Add (0.1 x % accuracy) per °C from 0 to 18°C,

and from 28 to 50°C.

Maximum altitude: 2,000m.

Battery: 1 x 9 volt, type PP3, MN1604, NEDA1604, JIS006P, IEC 6F22.

Battery life: 200 hours, typical (Zinc - carbon).

Dimensions: 143 x 68 x 47mm (5.6 x 2.7 x 1.9 inches).

Weight: 206g (7.3oz) with battery fitted.

Included: Set of test leads, 9V battery (fitted) & user manual.

DC VOLTS

Ranges: 200mV, 2V, 20V, 600V.

Resolution: 100µV

Accuracy: ± 1.2% rdg + 1 digit

Input impedance: 10MΩ

Overload protection: 600V DC or AC rms

500V DC / 350V rms for 15 secs on 200mV range

AC VOLTS (50Hz to 500Hz)

Ranges: 200mV, 2V, 200V, 600V

Resolution: 100µV

Accuracy: ± (2% rdg + 4 digits)

Input impedance: 10MΩ

Overload protection: 600V DC or AC rms

500V DC / 350V rms for 15 secs on 200mV range

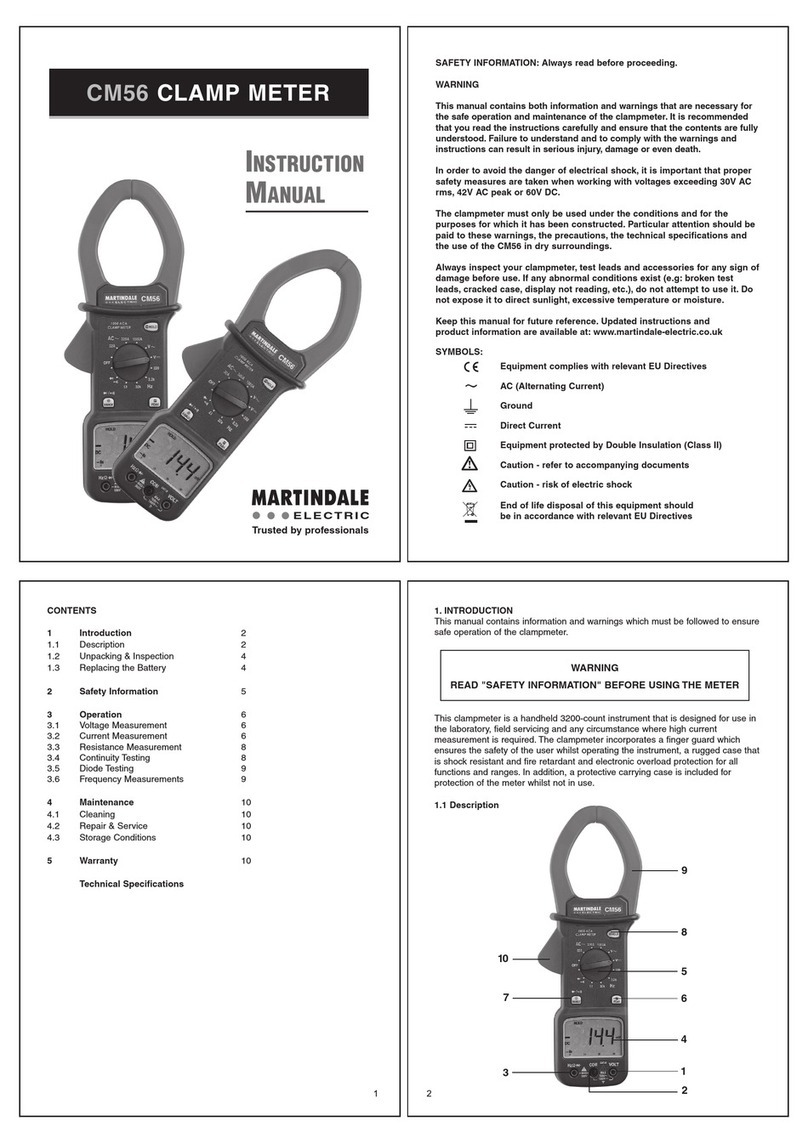

3. OPERATION

3.1. Precautions

Warning: Before using the instrument, read the Safety Information

Section, and examine it for damage or contamination (excessive dirt,

grease, etc.). Check the test leads for any evidence of cracked or

frayed insulation. If any abnormal conditions exist, do not use the

meter.

Warning: When using probes, keep your fingers behind the guards.

Warning: Measuring voltages which exceed the limits of the meter

may damage it and expose the operator to a shock hazard. Always

work within the meter voltage limits indicated on it's front panel.

Warning: Never ground yourself when taking electrical

measurements. Do not touch exposed metal pipes, outlets, fixtures

etc. which may be at ground potential. Keep your body insulated by

wearing dry clothing, rubber shoes or stand on a rubber mat, or other

suitable material.

3.2 Voltage measurement

1. Connect the red test lead to the "VΩ" socket, and the black lead to the

"COM" socket.

2. Select the correct function & range using the rotary switch, ensuring that

AC, or DC, ranges are chosen as appropriate. If the magnitude of the

signal is uncertain, then begin with the highest setting, and reduce it until a

satisfactory indication is obtained.

3. Connect the other end of both test leads to the unit under test.

4. In the DC function a "-" is displayed for negative values, positive

indication is implied.

58