7

MAN x ½ the instrument performs the test with a leakage current at ½x

the value of the rated current indicated, with the leakage current

in phase with the voltage or phase shifted by 180° with respect

to the voltage.

MAN x 1 the instrument performs the test with a leakage current at 1x the

value of the rated current indicated, with the leakage current in

phase with the voltage or phase shifted by 180° with respect to

the voltage.

MAN x 2 the instrument performs the test with a leakage current at 2x the

value of the rated current indicated, with the leakage current in

phase with the voltage or phase shifted by 180° with respect to

the voltage.

MAN x 5 the instrument performs the test with a leakage current at 5x the

value of the rated current indicated, with the leakage current in

phase with the voltage or phase shifted by 180° with respect to

the voltage

AUTO the instrument performs the test automatically with a leakage

current at ½x, 1x, 5x the value of the rated current indicated with

the leakage current in phase with the voltage and then phase

shifted by 180° with respect to the voltage. Recommended test.

.

RAMP Mode the instrument performs the test with a steadily increasing

leakage current, with the leakage current in phase with the

voltage or phase shifted by 180° with respect to the voltage.

Use this test to measure the tripping current.

UtMode the instrument performs the test with a leakage current equal to

½ the value of the rated current indicated and calculates the

contact voltage as well as the Ra earth resistance with the

leakage current in phase with the voltage or phase shifted by

180° with respect to the voltage.

Readings below 1Ω are displayed as 1Ω.

PLEASE NOTE:

MAN x5 and auto test modes are not available for RCD type A, 500mA

8. INSTRUMENT CONNECTION TO PC OR A PRINTER

The connection from the VR2240 to a PC is made using the optional infra red

data lead VRTL1 connected to the PC serial port. The optional software package

VRSOFT1 provides the facility to download and print results onto a form (All

items sold separately).

Before connecting the VR2240 to a PC, it is necessary to select and configure

the COM port on the PC used for data transfer. To set this, start the software and

refer to the help provided with the VRSOFT1 download application.

The selected port should NOT be shared by other devices or applications (eg.

mouse, modem, etc.).

The connection from the VR2240 to the printer VRPRINT1 is made using the infra

red data lead VRTL1, in conjunction with printer adaptor cable TL130 (all items

sold separately).

To transfer the stored data from the instrument to the PC or printer, follow the

directions below.

1. Turn the rotary switch to the RS232 position.

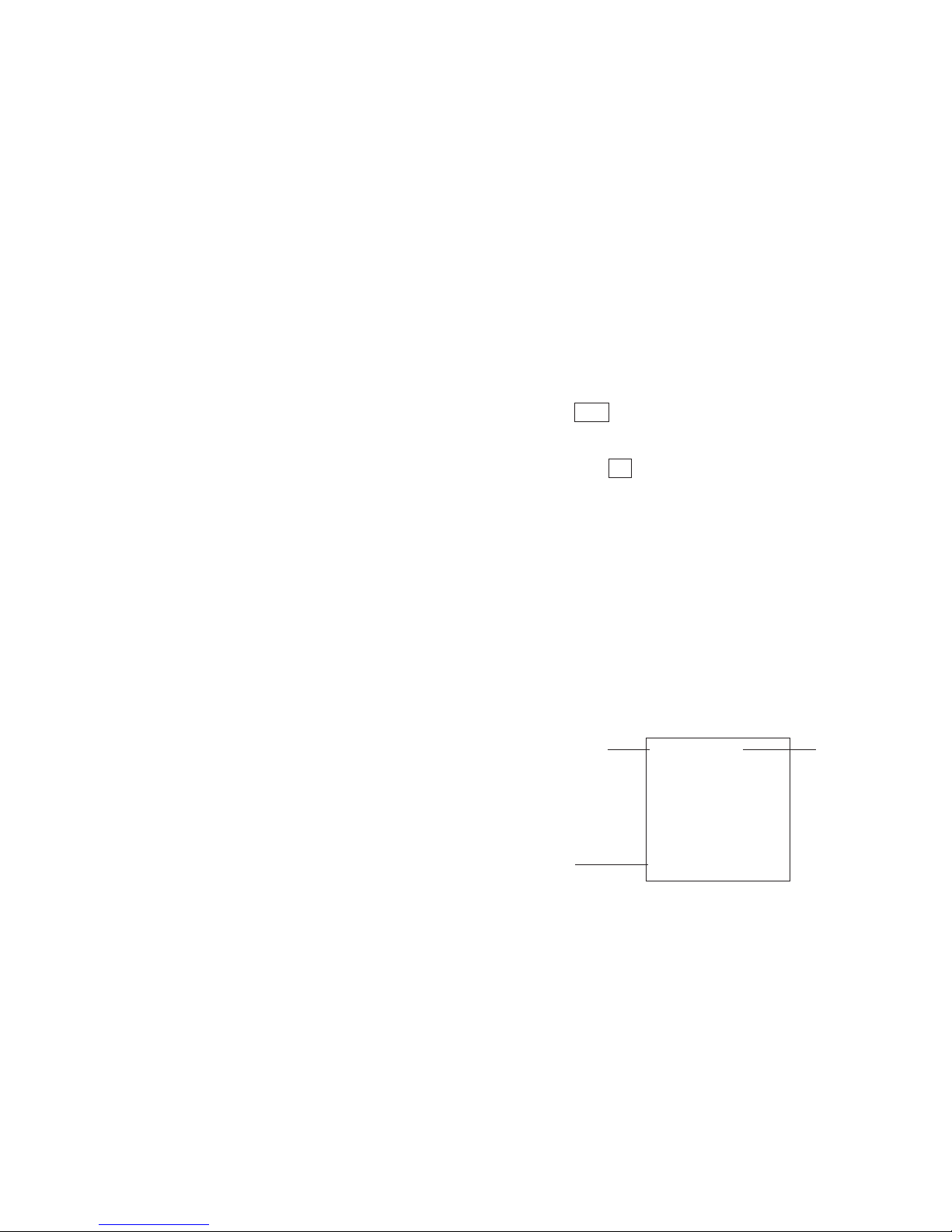

2. Using the FUNC key, select the modes "Prn ALL" or "Prn

n1 n2", to display the following screens respectively:

14

FUNC

Press GO to start printing all of the stored test

results.

Press ESC to stop printing immmediately.

indicates the total number of results

stored in memory.

Press GO to start printing the test results from

memory locations n1 to memory locations n2

inclusive. Note that the printing order is that of

the increasing value of the parameter P, NOT

memory location order. Ensure the range n1

to n2 covers all the results you need.

Press ESC to stop printing immediately.

indicates the memory cell which will

be printed as the last one.

Prn

All 125

Prn

13

25

Note Transmission speed on the PC or printer is set to 4800 baud to match

the output from VR2240.